An automatic cross-stitch needle threading device

A cross-stitch needle threading and transmission device technology is applied to embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc. It can solve the problems of not having the function of producing cross-stitching technology, and achieve a high degree of mechanical and electrical integration and good safety performance. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

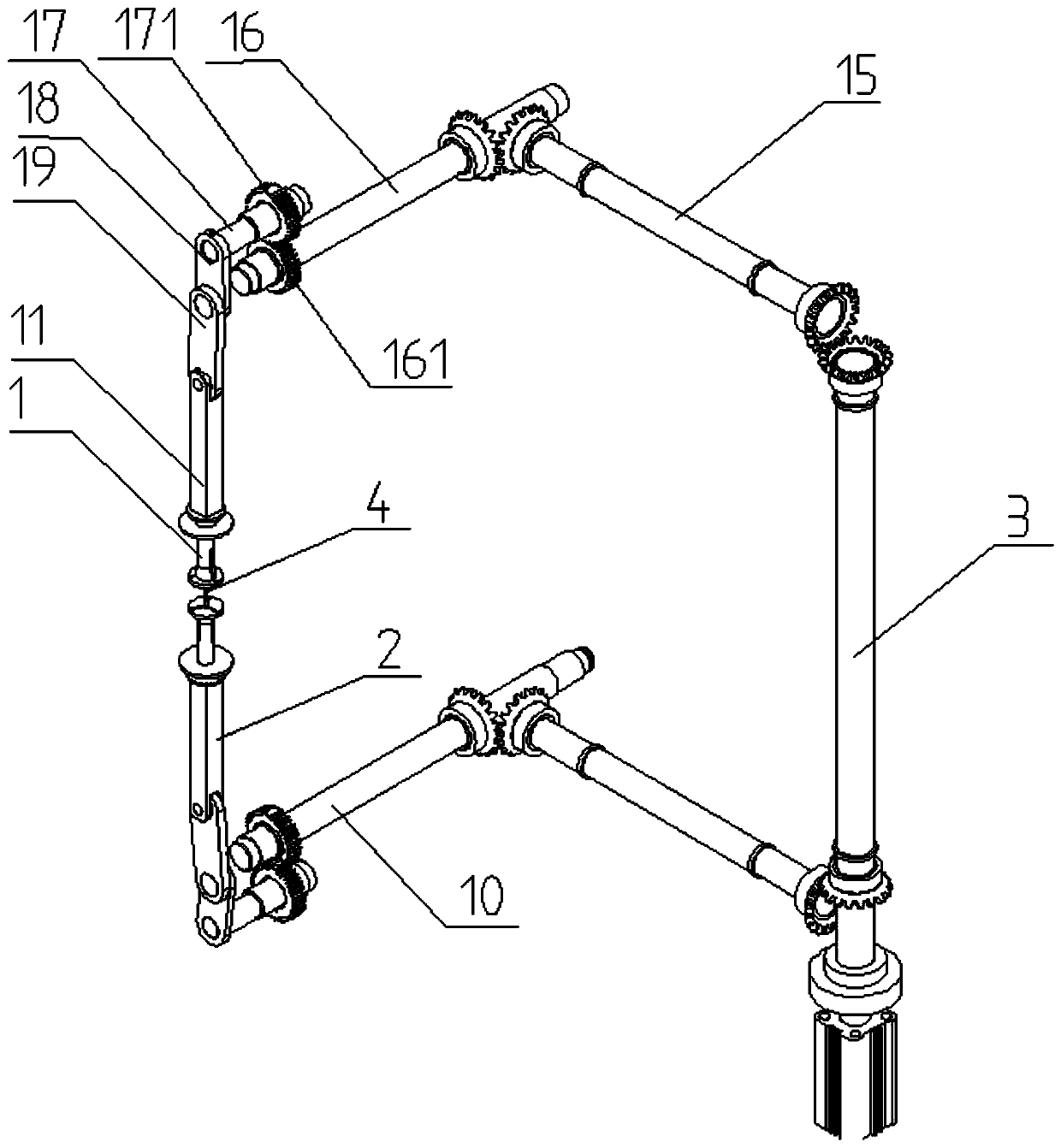

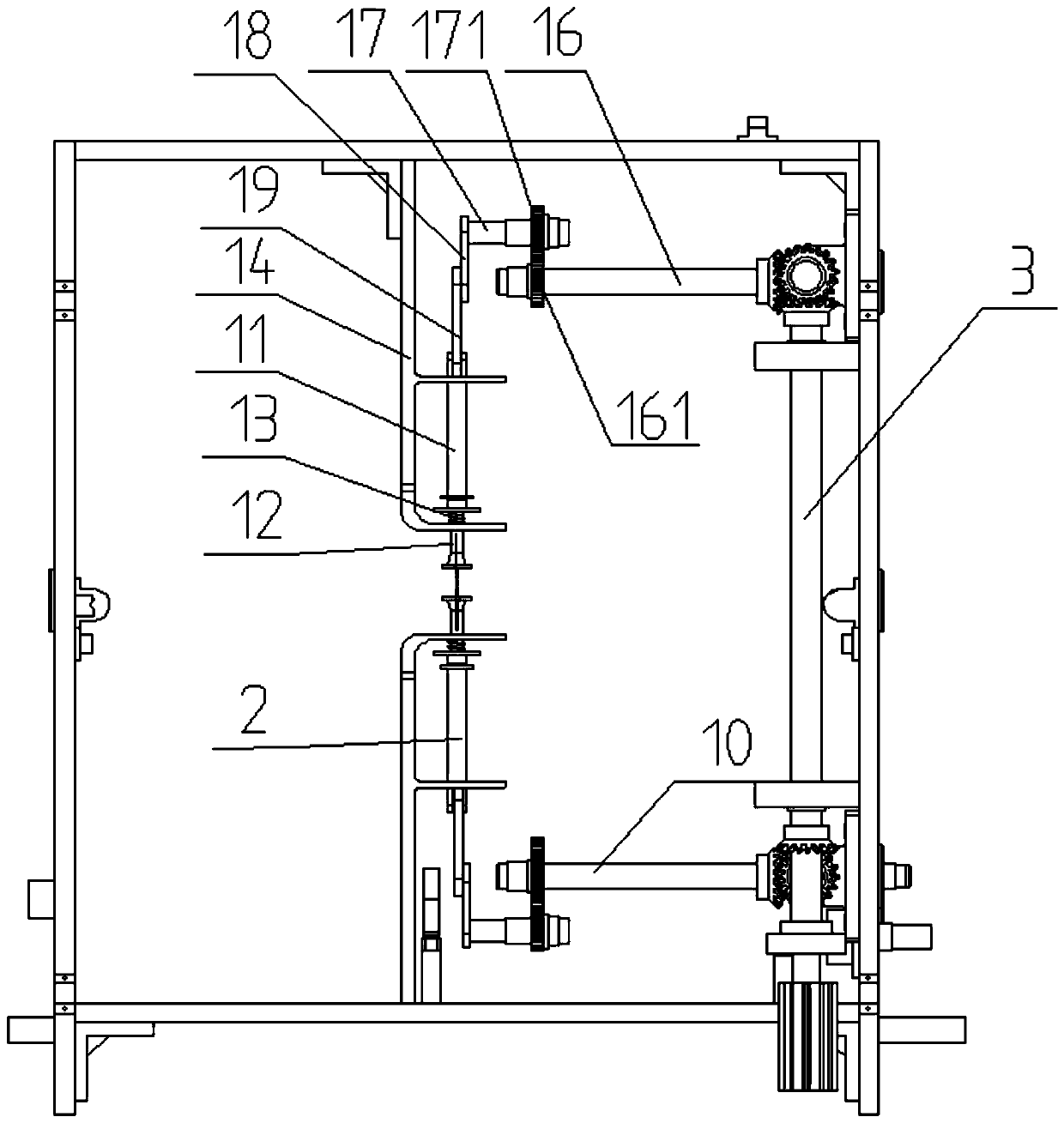

[0029] like Figure 1-Figure 2 As shown, an automatic cross-stitch needle threading device includes an upper needle clamping mechanism 1, a lower needle clamping mechanism 2, a needle clamping transmission device and a driving device, the upper needle clamping mechanism 1 is arranged above the embroidered cloth, and the lower clamping mechanism The needle mechanism 2 is arranged under the embroidered cloth, and the upper clamping mechanism 1 is used to clamp the embroidery needle and drive the embroidery needle to pass through the embroidered cloth from top to bottom, and release the embroidery needle after the embroidery needle passes through the embroidered cloth, The embroidery needles are delivered to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com