A demoulding machine for bathroom products and a demoulding process using the demoulding machine

A sanitary product and demoulding machine technology, which is applied in the field of demoulding technology, can solve problems such as difficult to control the impact force and product damage, and achieve the effects of increasing the demoulding speed, improving the impact efficiency, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

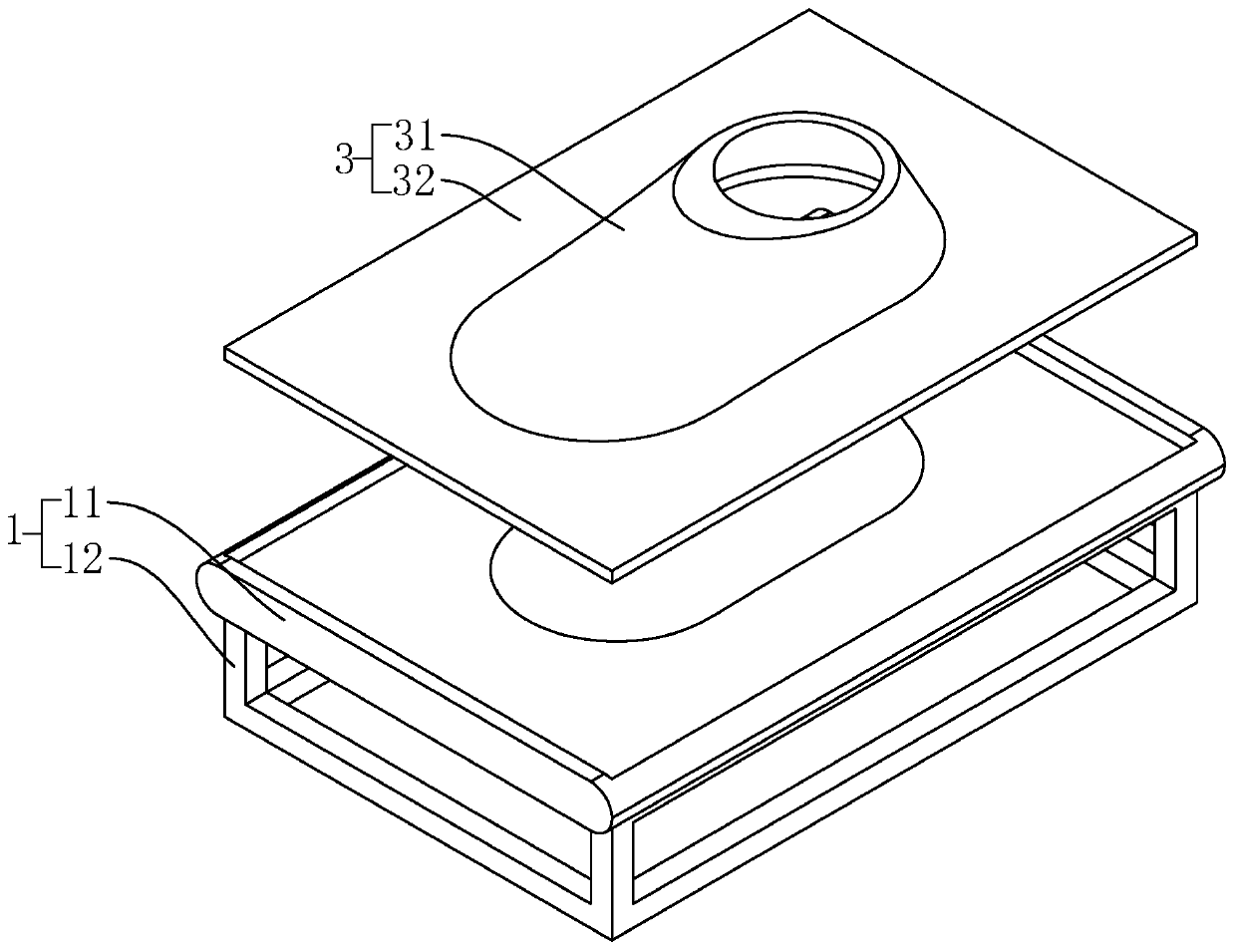

[0049] see figure 1 and figure 2 , a demoulding machine for sanitary products, including a demoulding frame 2 matched with a fixing frame 1. The fixed frame 1 includes a mold core 11 for product molding and a support seat 12 welded on the back of the mold core 11, and the cross-sectional area of the mold core 11 is rectangular. The product is bathroom washbasin 3. It includes a pot body 31 and a support plate 32 connected to the periphery of the pot body 31 for supporting the pot body 31 . The cross-sectional area of the support plate 32 is a rectangle similar to that of the mold core 11 .

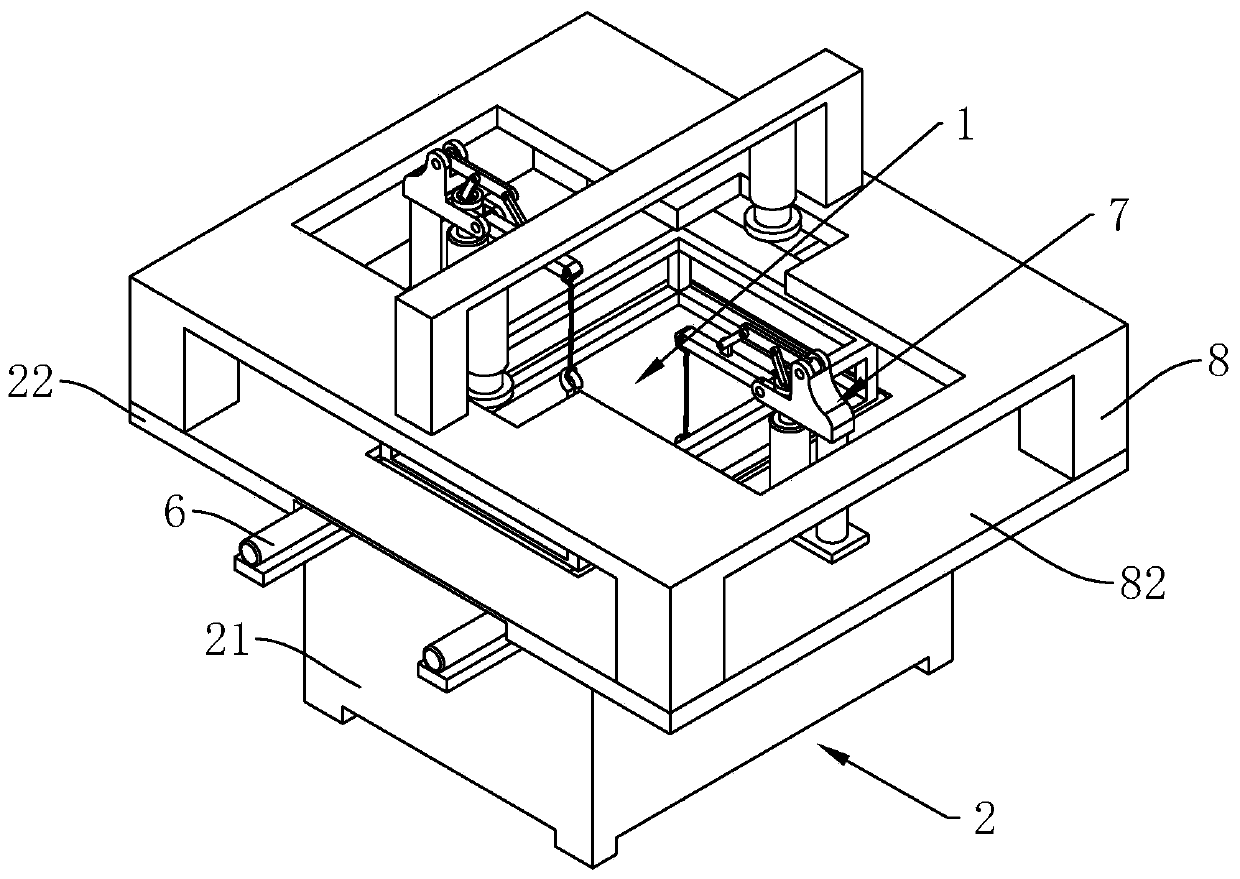

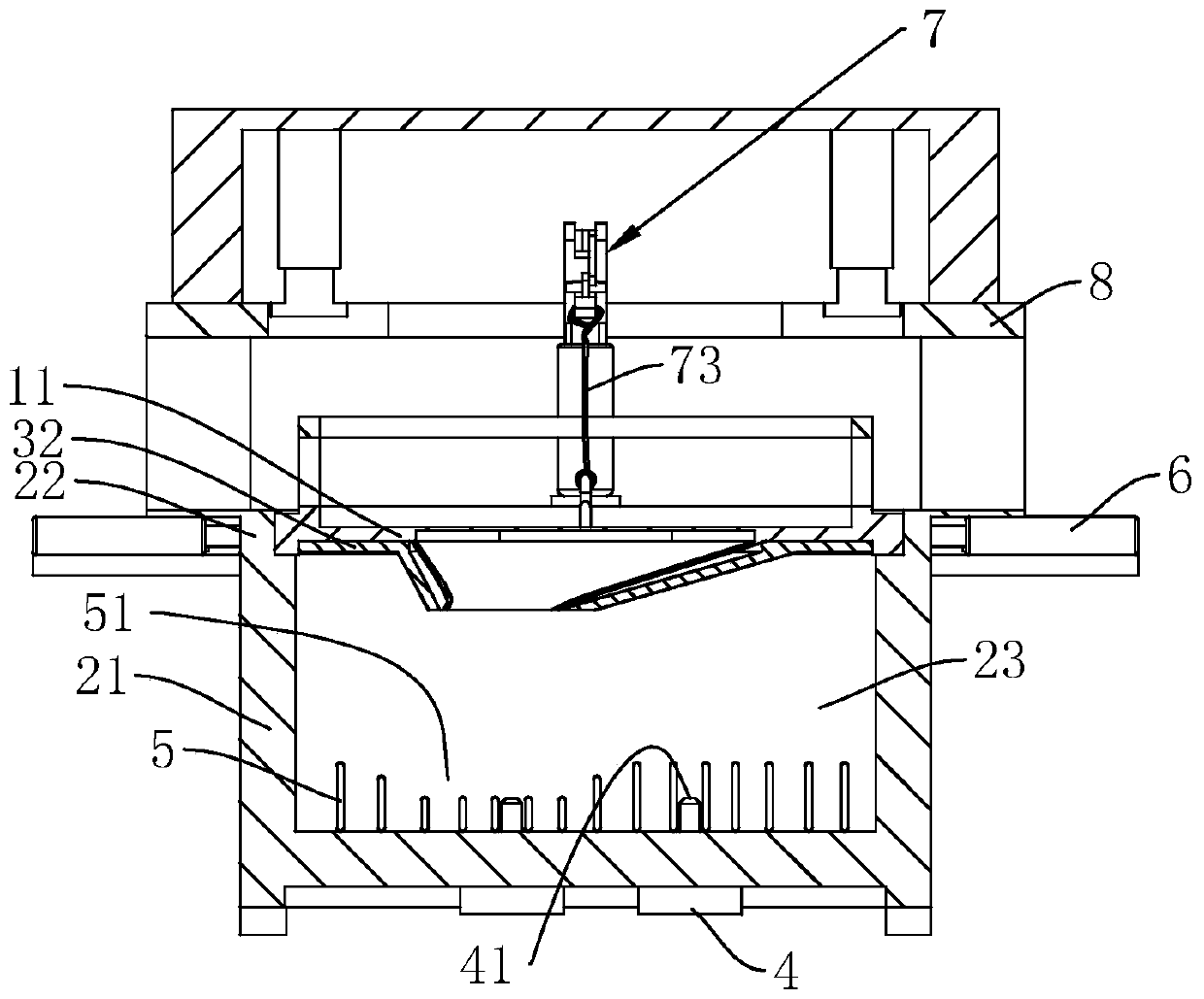

[0050] see figure 2 and image 3 The stripping frame 2 includes a frame body 21 , a positioning plate 22 installed on the frame body 21 , and a material receiving trough 23 opened on the frame body 21 and opening at the end surface of the positioning plate 22 . The opening area of the receiving trough 23 is larger than the cross-sectional area of the support plate 32 but sma...

Embodiment 2

[0057] see Figure 7 , a demoulding process, comprising the steps of:

[0058] Step1, disassemble the bathroom washbasin 3 after blister forming together with the fixing frame 1 from the mold;

[0059] Step2.1, transport the fixed frame 1 to the transmission trolley 92 located on the transmission rail 91, the support seat 12 of the fixed frame 1 is placed on the transmission trolley 92, and the transmission trolley 92 is provided with an installation groove for the support seat 12 to be embedded 921;

[0060] Step2.2, the transmission wheel 922 on the transmission trolley 92 cooperates with the transmission rail 91, so that the transmission trolley 92 transports the fixed frame 1 to the demoulding machine;

[0061] Step3.1, remove the fixed frame 1 from the transfer trolley 92, send the side of the fixed frame 1 adhered to the bathroom wash basin 3 towards the receiving tank 23 from the opening 82 of the coaming plate 8 into the demoulding frame 2, and embed it for positioni...

Embodiment 3

[0069] Embodiment 3 is substantially the same as Embodiment 2, the only difference being that the number of impacts of Step 3.4 and Step 4.1 is controlled to 7 times; Step 3.1 to Step 4.1 are repeated three times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com