Water-containing plate assembly and lower air outlet machine room air conditioner

A technology of water trays and components, applied in air conditioning systems, prevention of condensed water, space heating and ventilation, etc., can solve the problems of large pressure difference, unable to discharge in time, and affect the normal operation of the machine, so as to facilitate collection and improve replacement The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

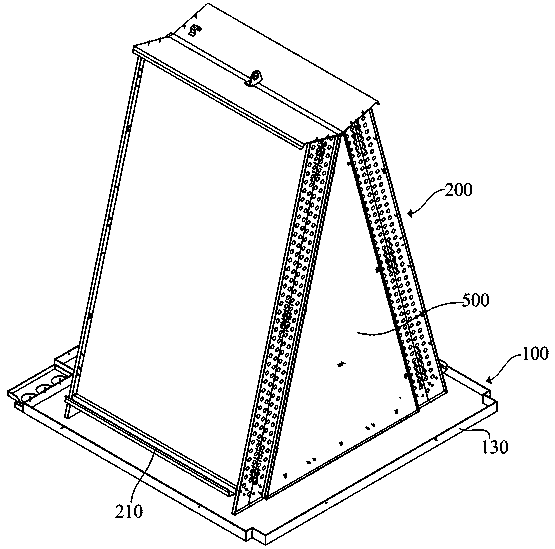

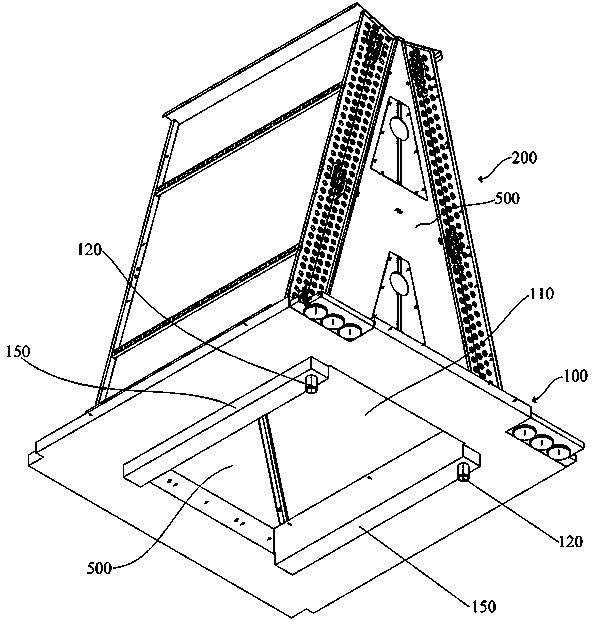

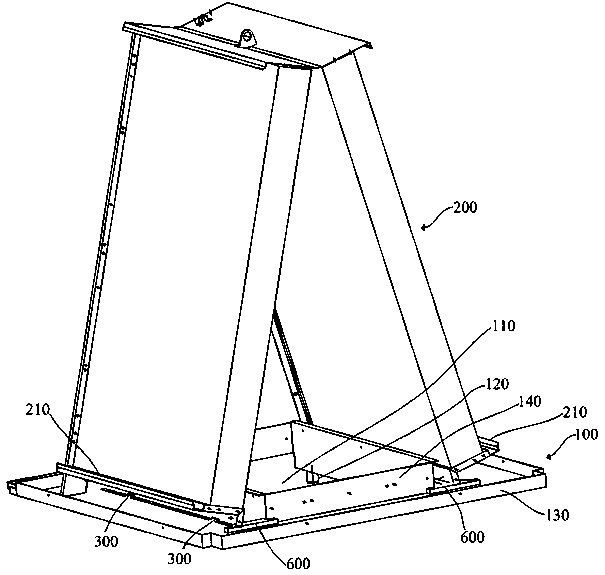

[0029] Such as Figure 1 to Figure 6 As shown, a water tray assembly in this embodiment includes a water tray body 100 and a heat exchanger 200, the heat exchanger 200 is installed on the water tray body 100 with its bottom end, and the water tray body 100 is provided with Ventilation holes 110 and drain ports 120, the surrounding edges of the water tray body 100 have upwardly turned outward flanges 130, the surrounding edges of the ventilation holes 110 are provided with upwardly folded internal flanges 140, and the lower end of the heat exchanger 200 is located at The outside of the inner flange 140; different from the prior art, the water receiving tray body 100 in this embodiment is also provided with a water storage groove 150 that is sunken downward relative to the water receiving tray body 100, and the water outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com