A sunroof windshield installation assembly

A windshield and assembly technology, applied in the field of sunroof windshield installation assembly, can solve the problems of loose mounting support, many parts, complicated assembly, etc., and achieve the effect of reducing installation inconvenience and easy loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

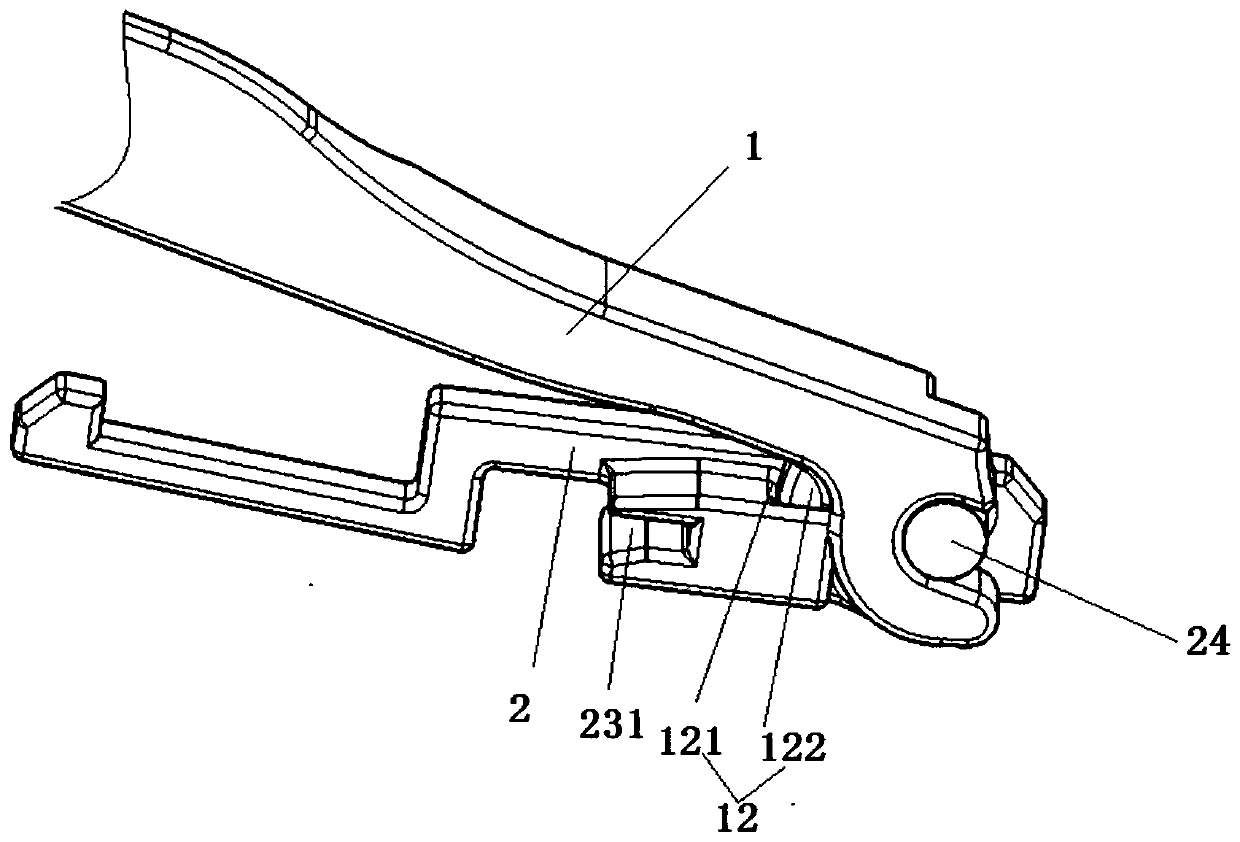

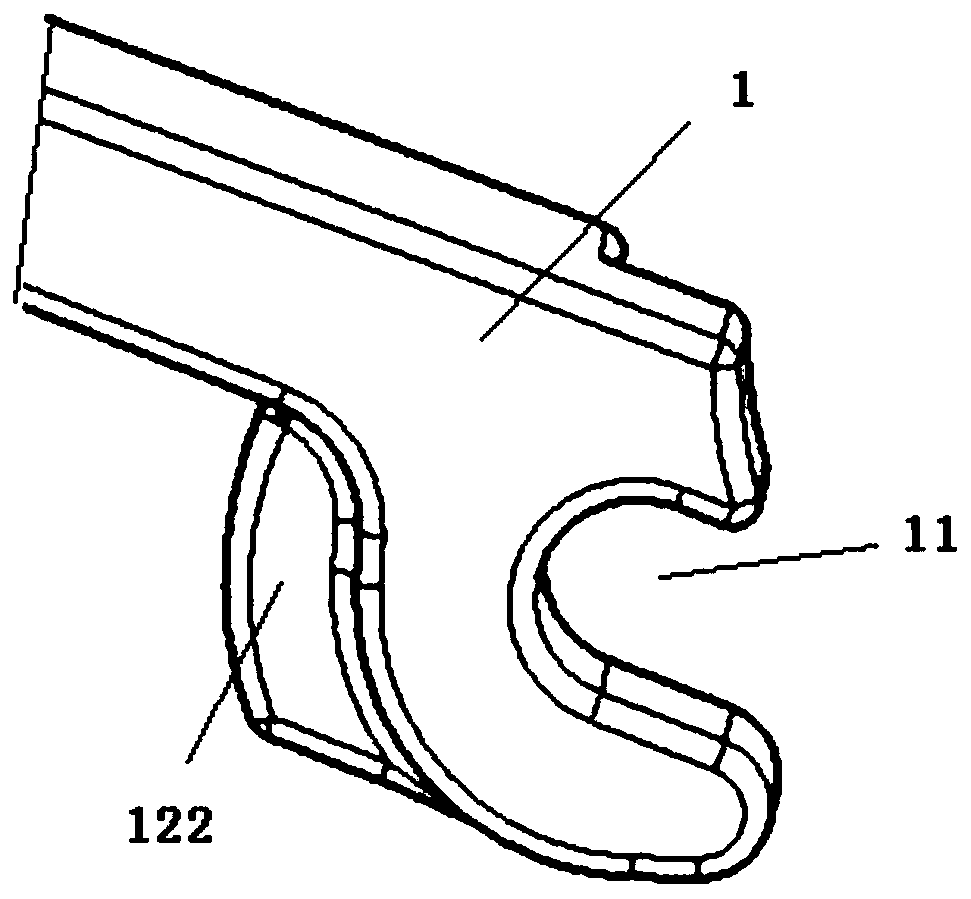

[0032] Embodiments of the present invention: as figure 1 As shown, a sunroof windshield installation assembly is disclosed, including a support 1, a mounting seat 2 and a guide rail 3, wherein one end of the support 1 is fixedly connected to the windshield, and the other end of the support 1 is connected to the mounting seat 2 Relative rotation, wherein the mounting base 2 is fastened on the guide rail 3 . In this way, the support base 1 can drive the windshield to rotate around the installation base 2 to realize the lifting of the windshield, and the installation base 2 is fastened on the guide rail 3 to avoid installation inconvenience during the bolt-fixed connection process and after installation. The case of loose screws.

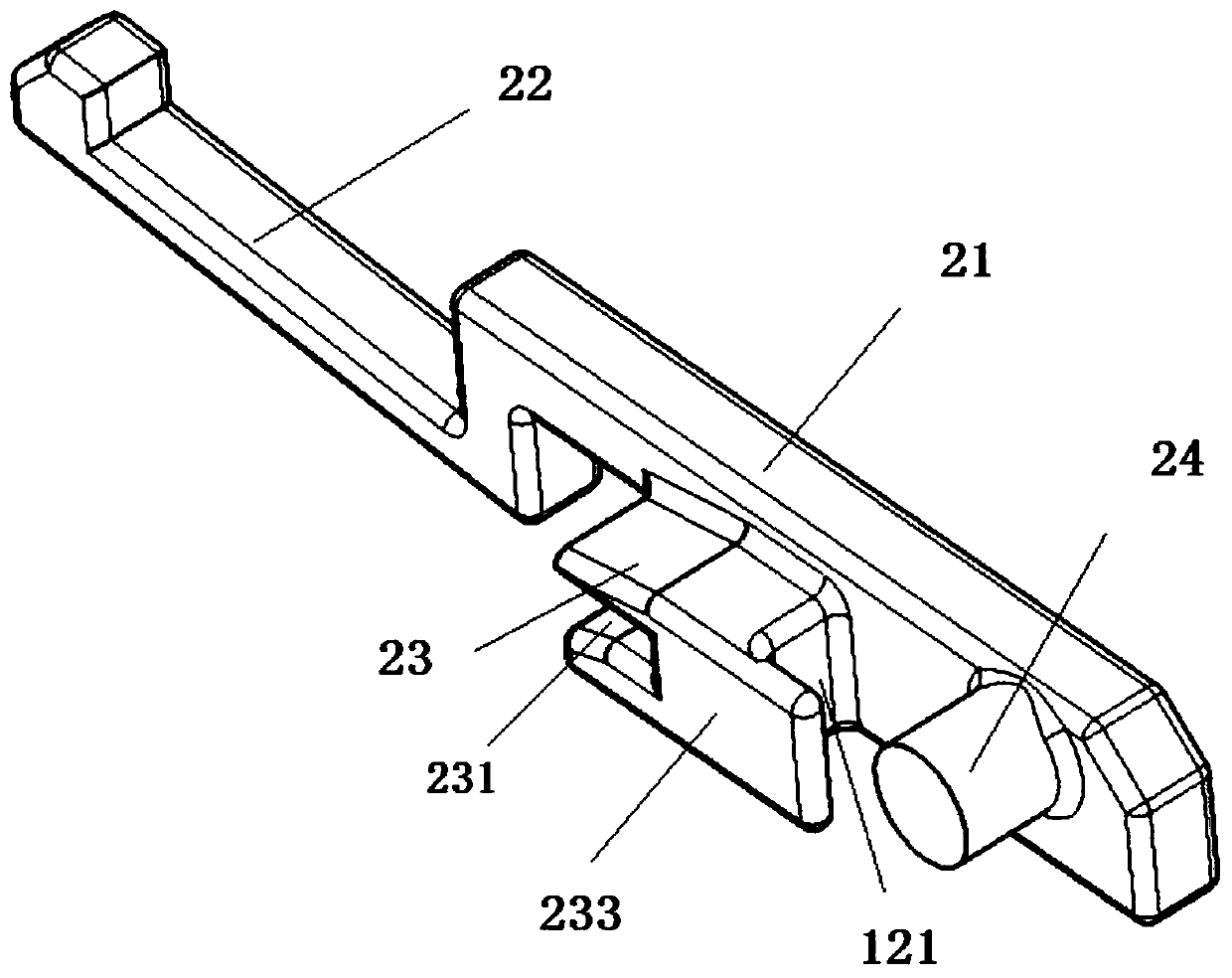

[0033] Specifically, such as image 3 As shown, the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com