High-efficiency heat-dissipating device for battery of electric vehicle

A technology for electric vehicles and cooling devices, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of large cooling equipment, impact on the performance of battery equipment, and large space in the car, so as to improve the comprehensive utilization of resources High efficiency, realization of recycling rate, flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

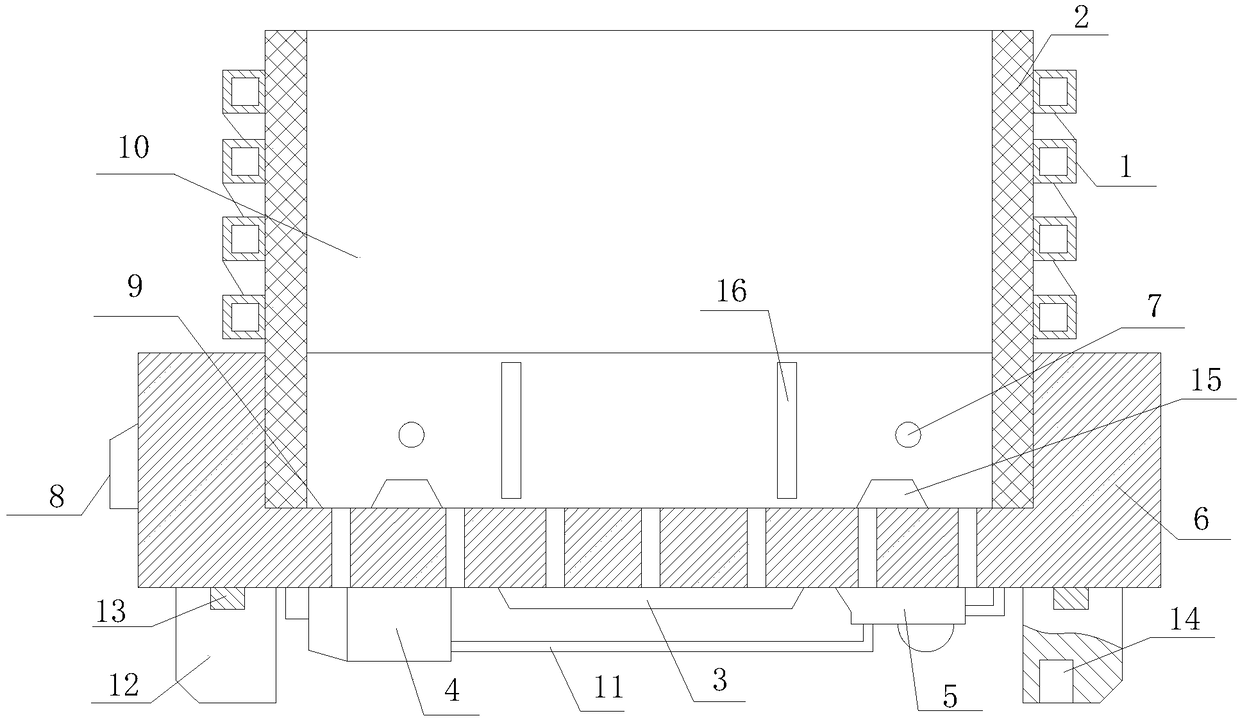

[0016] Such as figure 1 The high-efficiency heat dissipation device for an electric vehicle battery includes a heat exchange tube 1, a heat exchange plate 2, a thermoelectric power generation device 3, a semiconductor refrigeration device 4, a ventilation fan 5, a bearing base 6, a temperature sensor 7 and a control circuit 8, The upper end surface of the bearing base 2 is provided with a positioning groove 9 with a cross-section in the shape of "凵", a number of through holes 10 are evenly distributed on the lower end surface, and at least one heat exchange tube 1 is installed on the upper end surface of the bearing base 6, and the axis of the positioning groove 9 is in a spiral shape. structural distribution, and form a tubular structure heat exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com