Water jet robot control system and method

A control system, water jet technology, applied in the direction of program control manipulator, manipulator, manufacturing tools, etc., can solve the main structure damage, shorten the main structure engineering life, easily damaged steel bars and other problems, to improve the operation accuracy, reduce invisible damage, The effect of guaranteeing the life of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

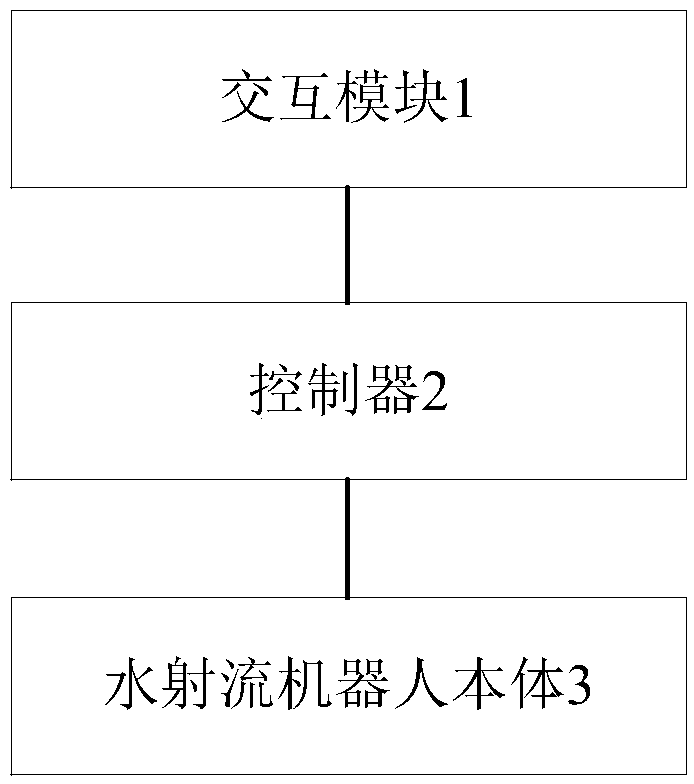

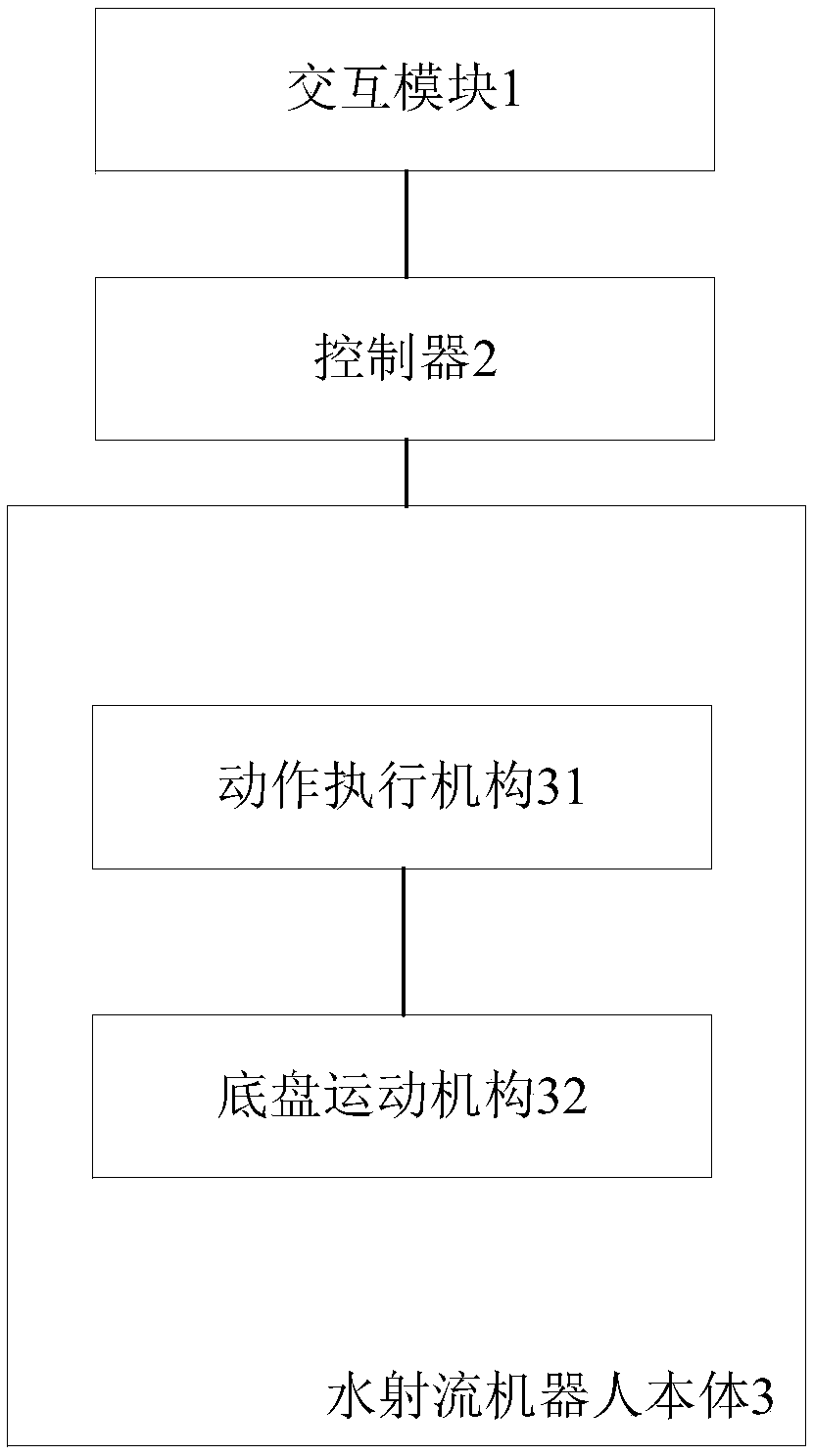

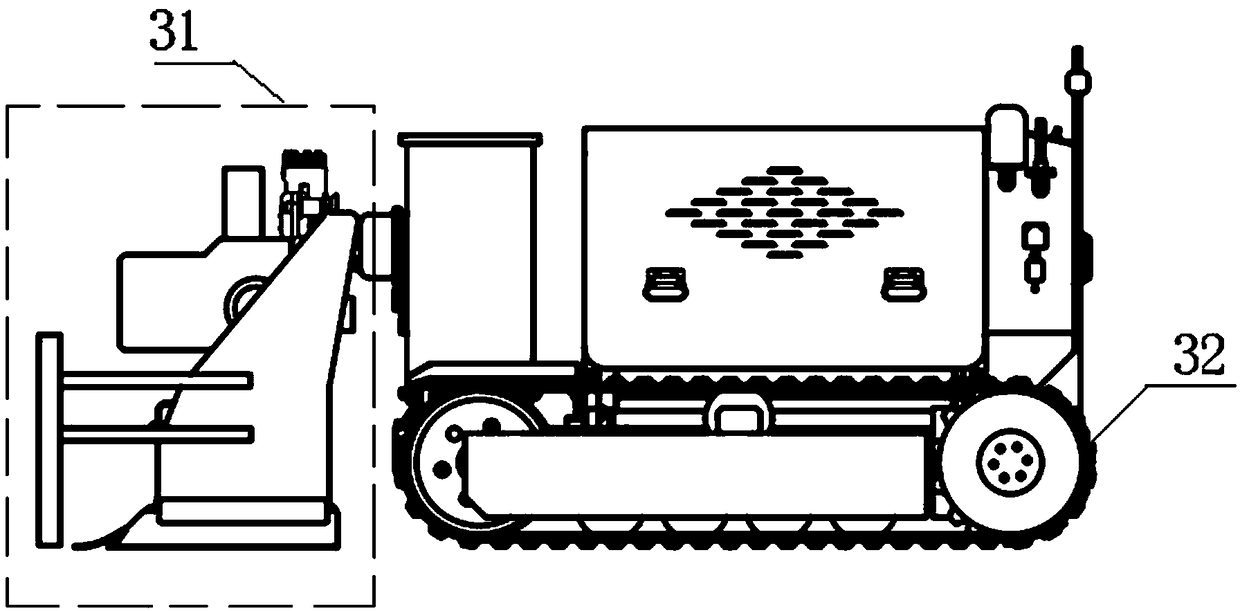

[0039] An embodiment of the present invention provides a water jet robot control system, such as figure 1 As shown, the water jet robot control system includes: an interaction module 1, a controller 2, a water jet robot body 3, and the like.

[0040] Among them, the interaction module 1 is used to obtain the operation tasks and operation parameters set by the user. The operation tasks include the operation area and operation depth that need to be crushed, and the operation parameters include the operation range parameters and the output pressure of the high-pressure pump in the water jet robot. Adjustment parameters and the position parameters and rotation angle parameters of the water jet spray gun 313, etc., in practical applications, the interaction module 1 can be, for example, a touch display screen, which has a good human-computer interaction interface to complete the user's parameter setting , the touch display screen is directly connected with the controller 2 by means...

Embodiment 2

[0059] An embodiment of the present invention provides a water jet robot control method, such as Figure 10 As shown, the water jet robot control method includes:

[0060] Step S1: Obtain the job tasks and job parameters set by the user. For details, refer to the relevant description of the interaction module (1) in Embodiment 1.

[0061] Step S2: Adjust the working state of the water jet robot according to the working parameters. For details, refer to the relevant description of the controller (2) in Embodiment 1.

[0062] Step S3: The water jet robot body (3) executes the technological action at the position to be operated according to the operation task, and performs the operation. For details, refer to the relevant description of the water jet robot body (3) in Embodiment 1.

[0063] By executing the above steps S1 to S3, the water jet robot control method of the embodiment of the present invention realizes the remote automatic control of the water jet robot, improves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com