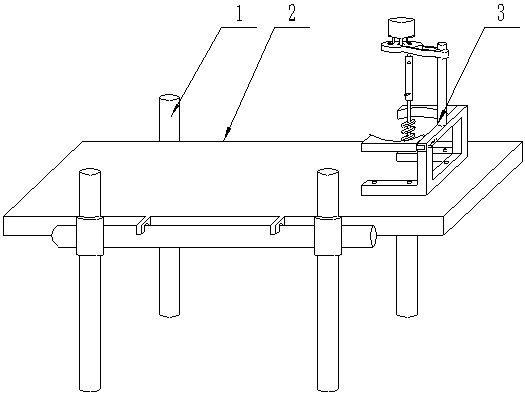

Scaffold for building construction

A technology for building construction and scaffolding, which is applied to scaffolding accessories, buildings, building structures, etc., can solve the problems of easy solidification of concrete, low safety factor, waste of time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

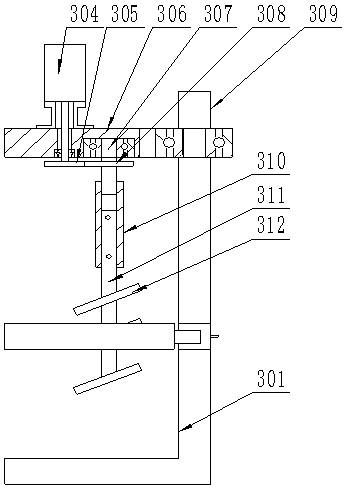

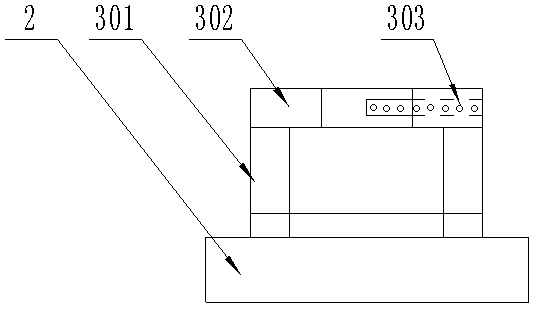

[0021] Specific implementation method: in the process of use, the user first places the bucket containing concrete on the bearing plate 2, pulls out the fixing pin, separates the fixing pin from pin hole 1 and pin hole 2, and moves the front splint 303 forward, The front clamping plate 303 moves forward to drive the slider to move forward inside the chute. When the front clamping plate moves to a suitable position, stop moving the front clamping plate 303, then place the bucket between the front clamping plate 303 and the rear clamping plate 302, and make the material The barrel and the rear splint 302 are closely attached, and the user pushes the front splint 303 backward, and the front splint 303 moves backward to drive the slider to move backward inside the chute. When the front splint 303 is closely attached to the barrel, stop pushing the front splint 303, the user connects the pin hole 1 and the pin hole 2 through the fixing pin, thereby fixing the bucket on the fixed fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com