A compound mold structure

A composite mold and template technology, which is applied in metal processing and other directions, can solve the problems of low efficiency, turning processing efficiency, and large waste, and achieve the effect of high efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

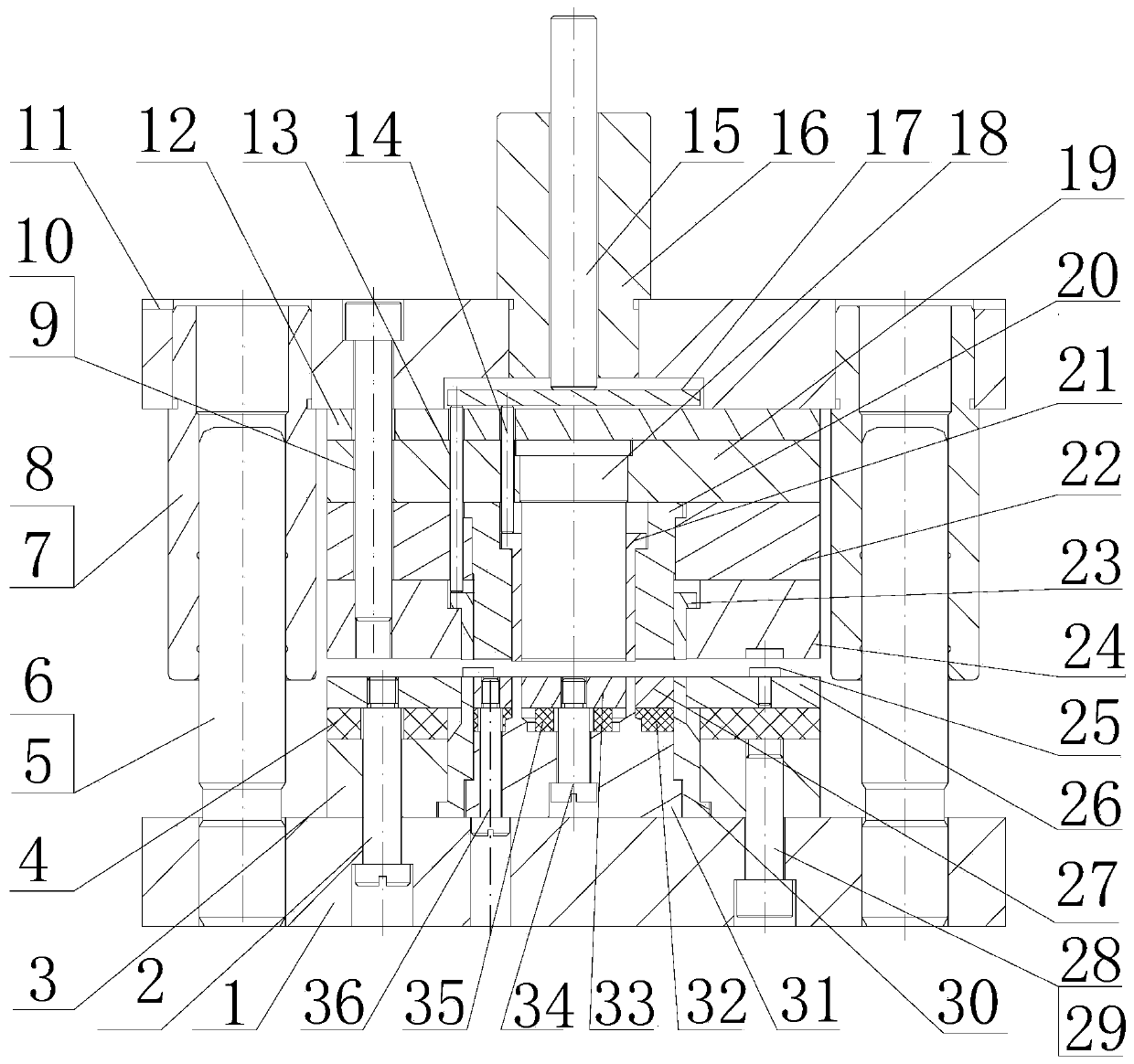

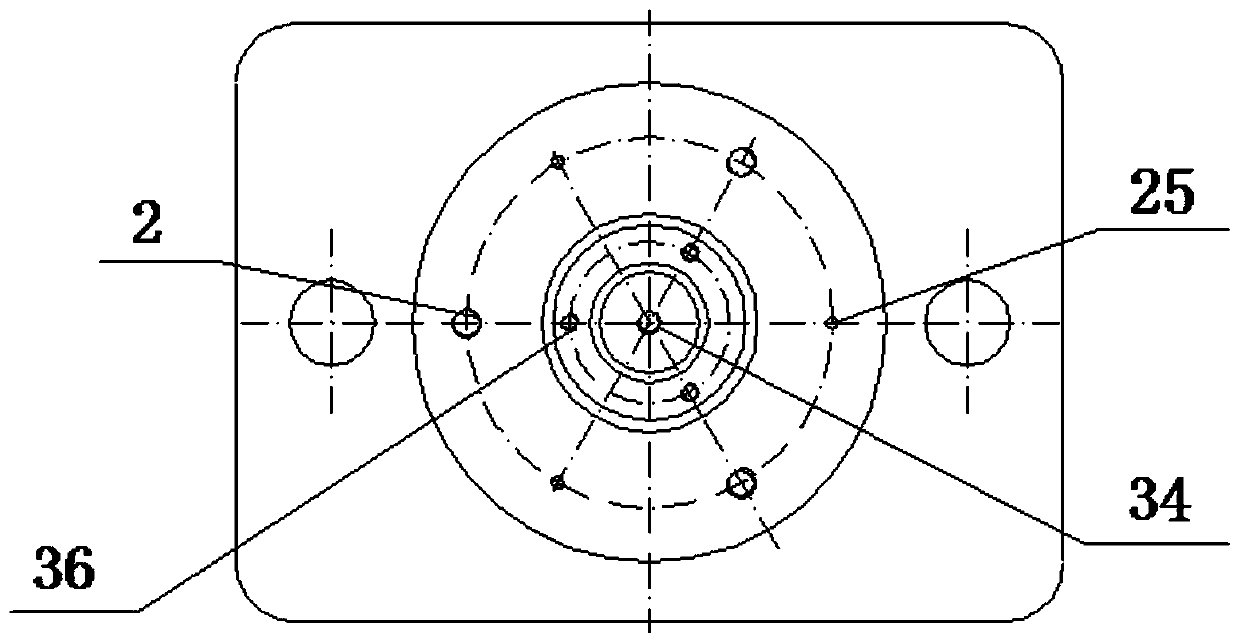

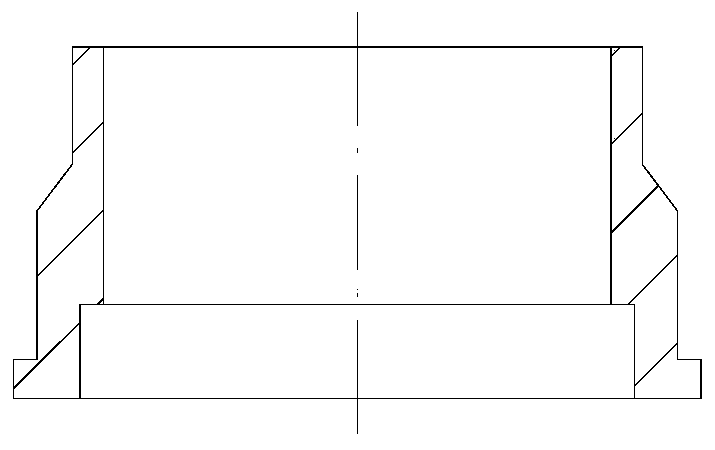

[0036] Such as figure 1 - Figure 16 As shown, the composite mold structure of the present invention includes an upper mold and a lower mold that are arranged oppositely.

[0037] The upper mold includes an upper template 11, an upper mold backing plate 12, a small punch splint 19, a large punch splint 22 and a large gasket shape blanking die 24 stacked from top to bottom, and the upper template 11, the upper mold backing plate 12. The small punch splint 19, the large punch splint 22 and the large washer-shaped blanking die 24 are fixedly connected into one body by three screws 9 and two pins 10, and the middle part of the upper template 11 is set and installed on the press The mold handle 16 on the slide block, the middle part of the mold handle 16 is sleeved with a punching rod 15, the bottom of the punching rod 15 is provided with a top plate 17, and the top plate 17 is embedded in the bottom of the upper template 11. The middle part of the small punch splint 19 is sandwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com