Elevator landing floor hole filling system and method thereof

A technology for elevator landings and holes, which is used in elevators, lifts, transportation and packaging in buildings, can solve problems such as occupying a large space, and achieve the effect of protecting safety and ensuring effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

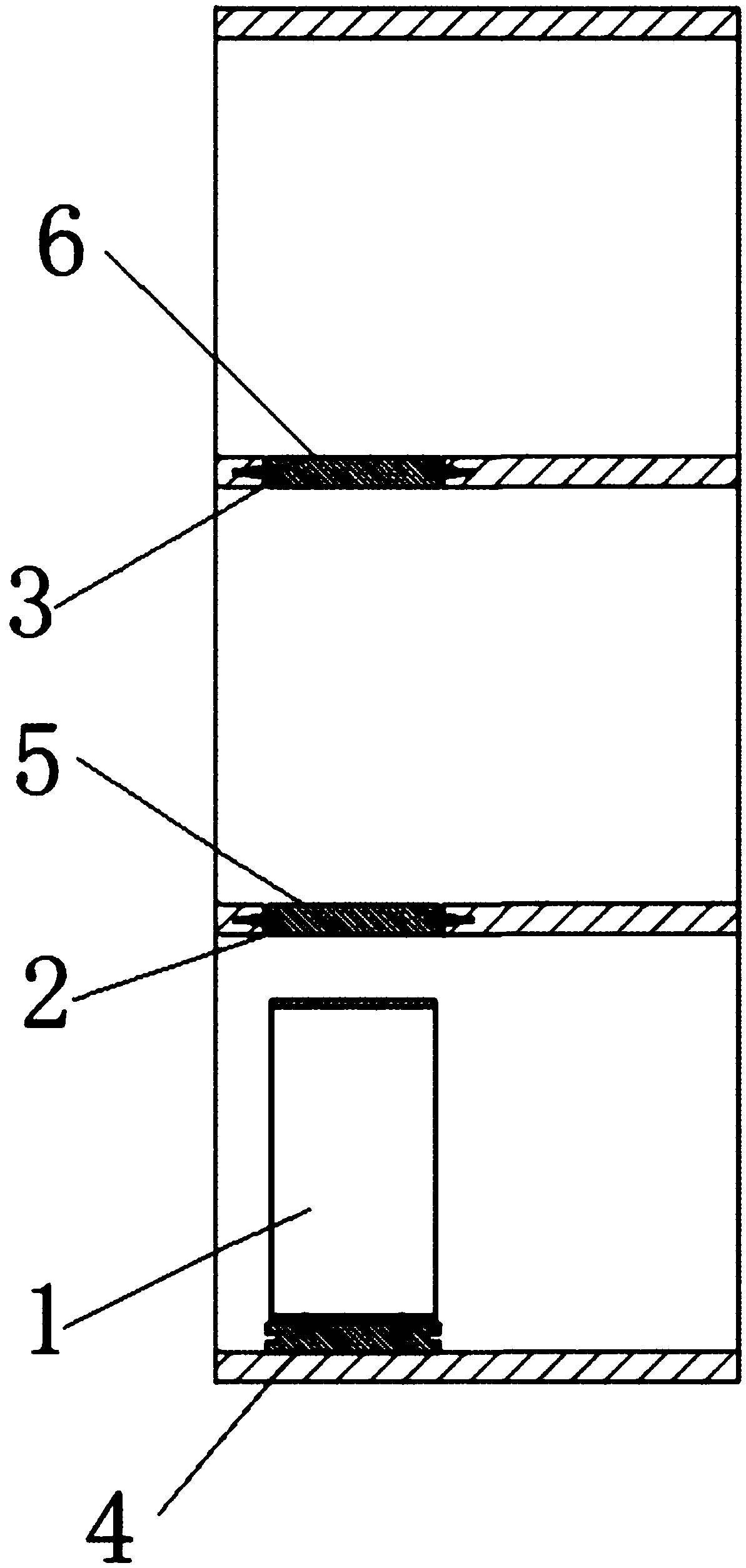

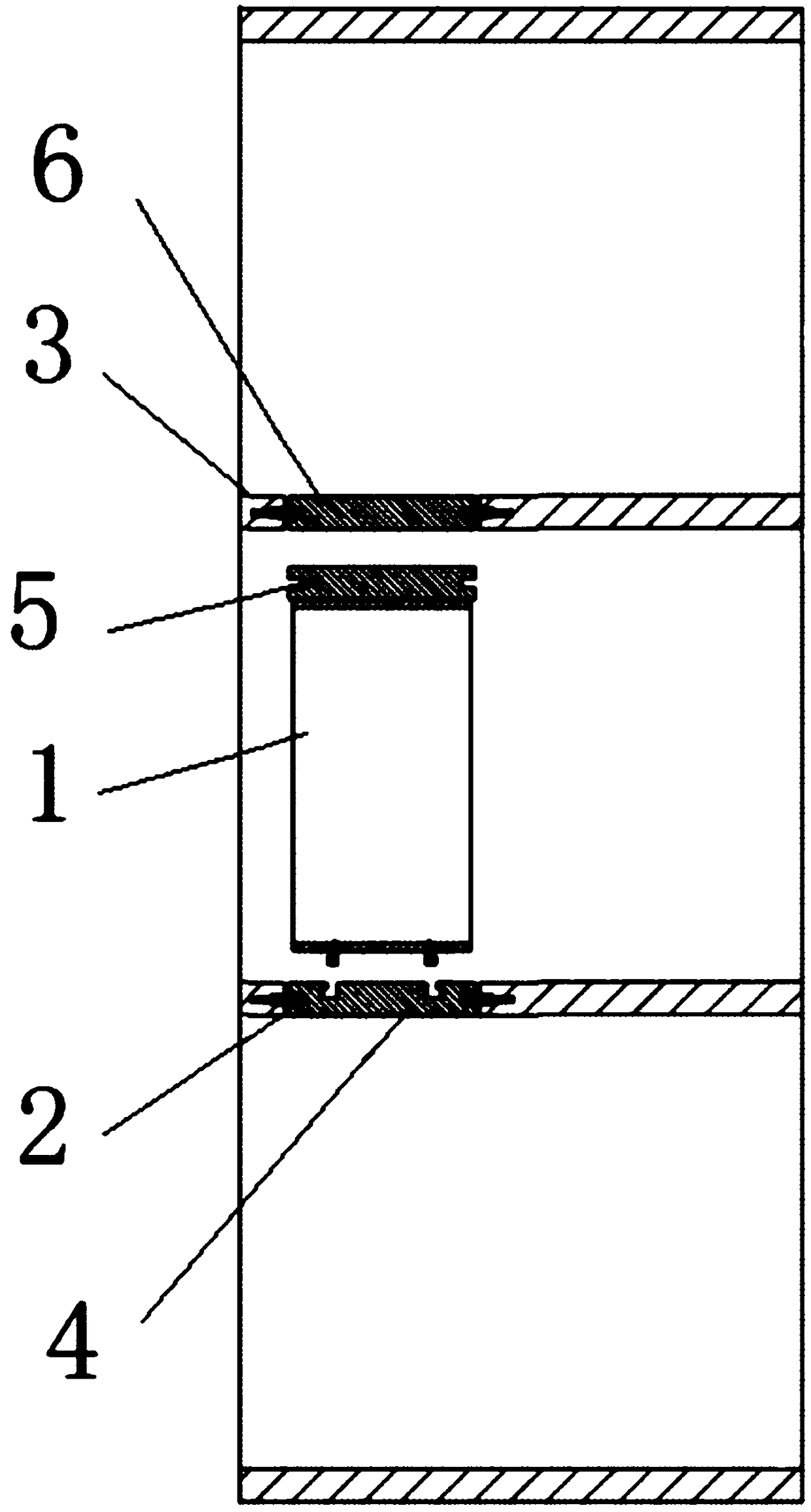

[0030] like Figure 1-5 As shown, the floor hole filling system of an elevator landing in this embodiment is used for a three-story elevator without a hoistway. The elevator includes an elevator control system, a car 1, a hole 2 on the second floor and a hole 3 on the third floor, and also includes a shape The car bottom cover plate 4, the second floor cover plate 5 and the third floor cover plate 6 matched with the hole 2 on the second floor and the hole 3 on the third floor, the bottom of the car 1 is connected with the car through the first normally closed electromagnetic opening and locking device 7. The bottom cover plate 4 is locked and fixed, the second floor hole 2 is locked and fixed with the second floor cover plate 5 through the second normally closed electromagnetic opening and locking device 8, and the third floor hole 3 is locked and fixed through the third normally closed electromagnetic opening and locking device 9 Locked and fixed with the cover plate 6 on the...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the elevator is an elevator with a shaft, the first normally closed electromagnetic opening and locking device is arranged on the car floor cover 4, and the second normally closed electromagnetic opening and locking device is arranged on On the cover plate 5 of the second floor, the third normally closed electromagnetic opening and locking device is arranged on the cover plate 6 of the third floor.

[0043] A method according to the above-mentioned elevator floor hole filling system:

[0044] When the elevator was on the first floor, the elevator control system controlled the first normally closed electromagnetic unlocking and locking device 7, the second normally closed electromagnetic unlocking and locking device 8 and the third normally closed electromagnetic unlocking and locking device 9, so that The car bottom cover plate 4 is locked and fixed on the bottom of the car 1, the second floor cover plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com