Fault detection early-warning device for shield pump

A technology for fault detection and shielded pumps, which is applied to components, pumps, and pump control of pumping devices for elastic fluids, to achieve the effect of solving the problem of eccentric wear monitoring and early warning under all working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

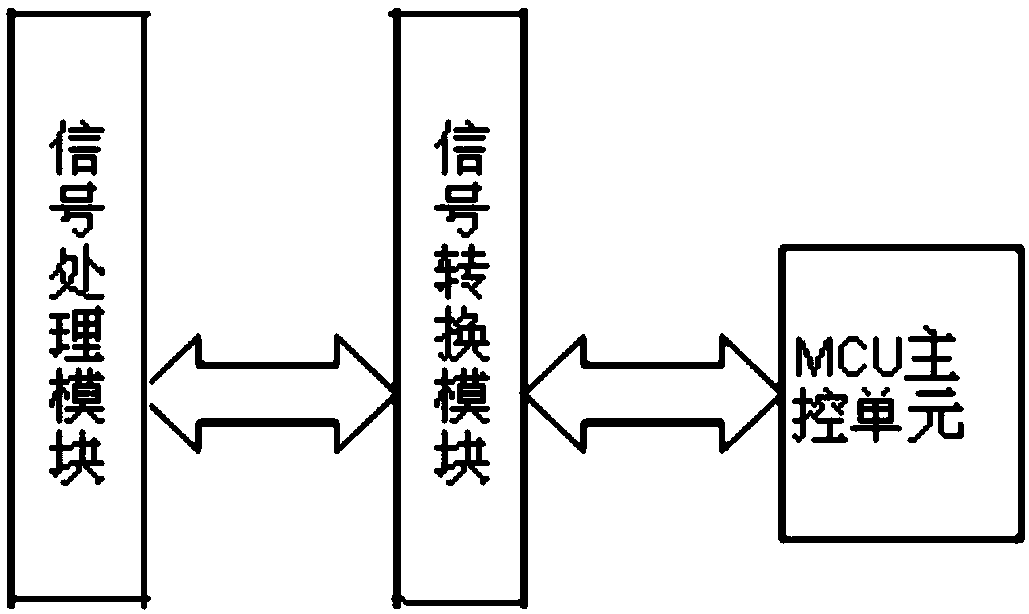

[0018] Such as figure 1 As shown, a fault detection and early warning device for shielded pumps includes a data acquisition unit, a display operation unit, a communication interface unit, a power supply unit, an MCU main control unit, and a fault detection sensor group, and the fault detection sensor group includes a deflection The detection coil and the acceleration vibration sensor placed in the direction perpendicular to the axis of the deflection detection coil, the stator winding temperature measurement sensor are PT-1000 thermal resistance and the stator space pressure measurement sensor, and the deflection detection coil and PT-1000 thermal resistance are respectively passed through the protective The line is connected with the data acquisition unit, which is used to collect the alternating voltage signal output by the deflection detection coil and the temperature me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com