Novel sizing machine for papermaking

A sizing machine, a new type of technology, applied in the field of sizing machines, can solve the problems of slow adjustment efficiency and complicated operation, and achieve the effect of convenient adjustment, simple operation and fast adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

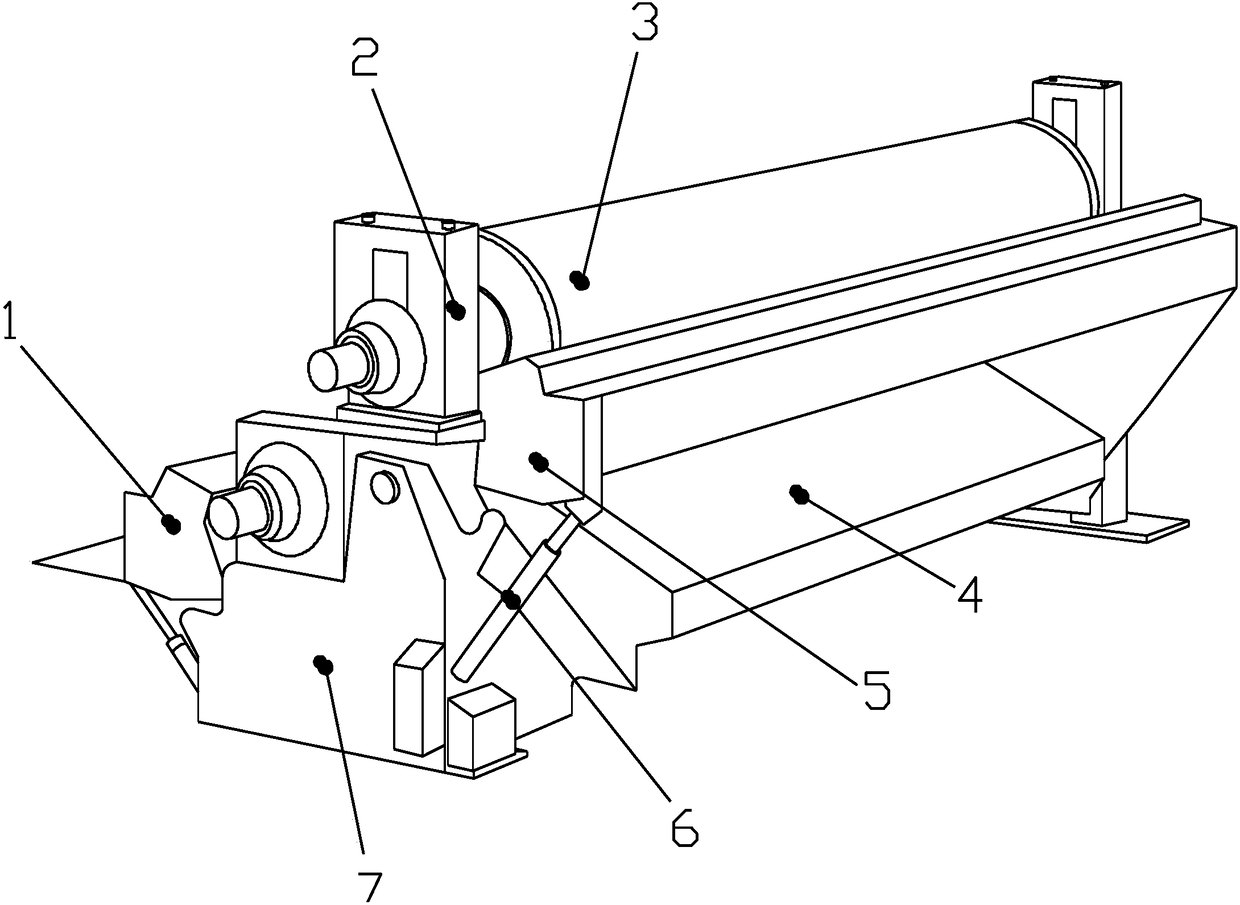

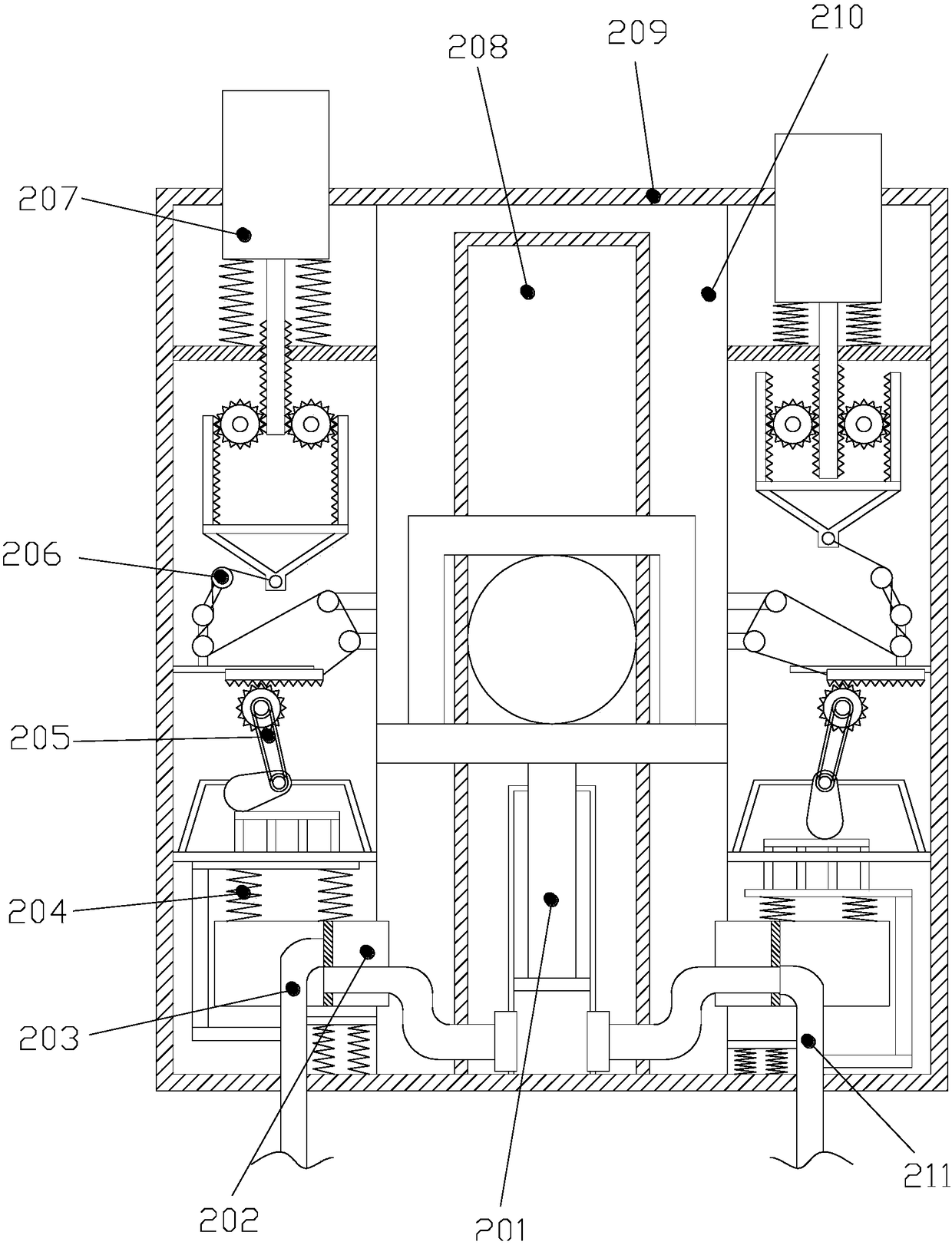

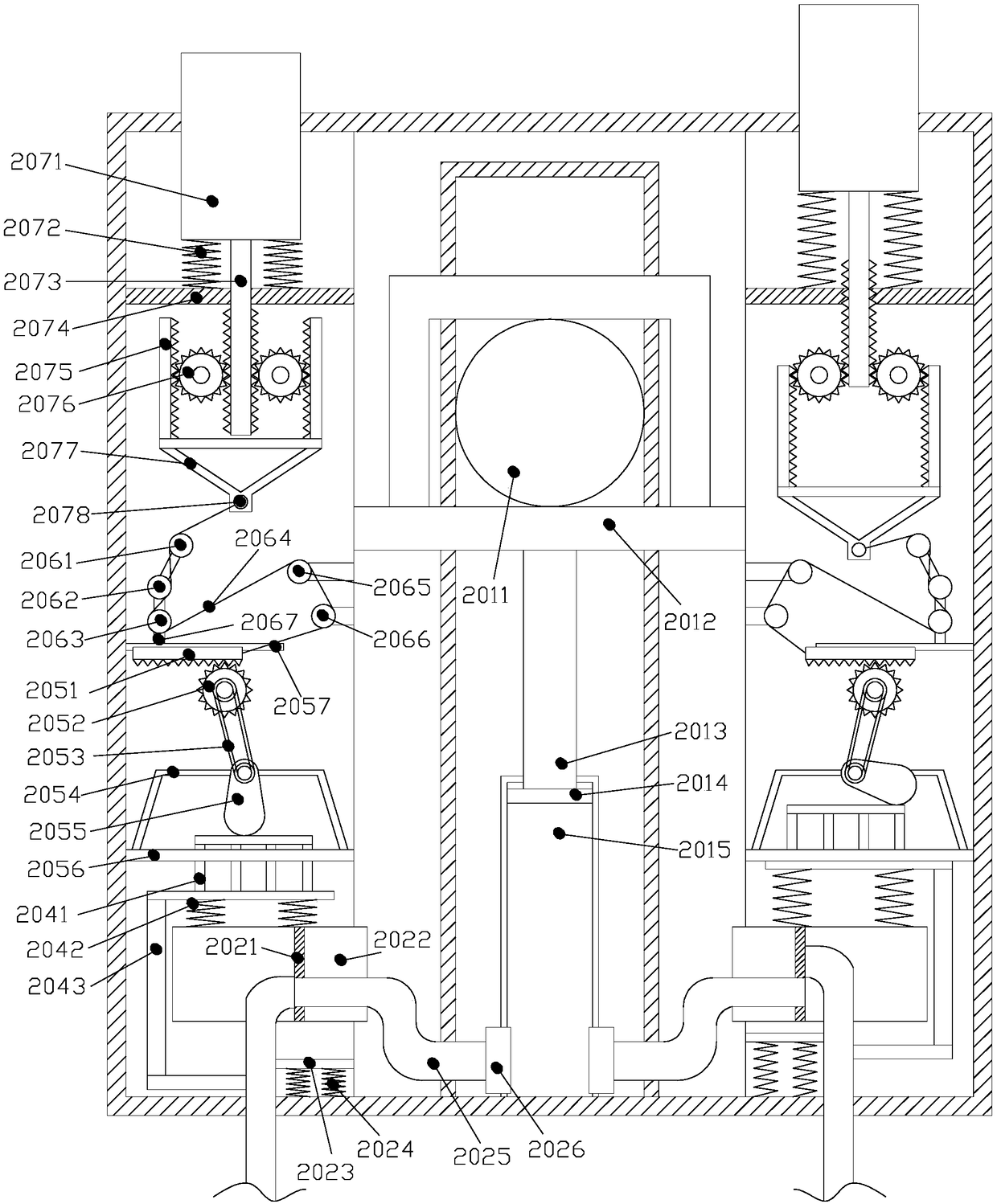

[0025] see Figure 1-Figure 5, the present invention provides a novel sizing machine for papermaking: its structure includes a paper inlet 1, a sizing roller bracket 2, a sizing roller 3, a paper outlet 4, a protective baffle 5, a support rod 6, and a body 7 , the paper inlet 1 is mounted on the rear end of the body 7 by fastening, the top ends of the body 7 are provided with grooves for the rubber roller bracket 2 of the movable device, and the two ends of the sizing roller 3 pass through The fastening mode is installed and connected with the sizing roller bracket 2, the rear end of the paper outlet 4 is installed on the bottom of the front end of the body 7 by embedding, and the protective baffle 5 is mounted on the upper end of the body 7 by buckling. The bottom of the protective baffle 5 is connected to the lower end of the machine body 7 through the support rod 6, and the sizing roller bracket 2 includes a lifting drive mechanism 201, an air connection mechanism 202, a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com