Impeller structure of mixed transportation pump

A mixed pump and impeller technology, applied to pumps, parts of pumping devices for elastic fluids, pump elements, etc., can solve the problems of increased hydraulic loss of stationary impellers, large vortices of stationary impellers, low efficiency of mixed pumps, etc. , to achieve the effects of reduced vortex and hydraulic loss, improved booster performance, and increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is specifically described below through the examples, the examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the contents of the present invention And adjustments also belong to the protection scope of the present invention.

[0022] In conjunction with the accompanying drawings.

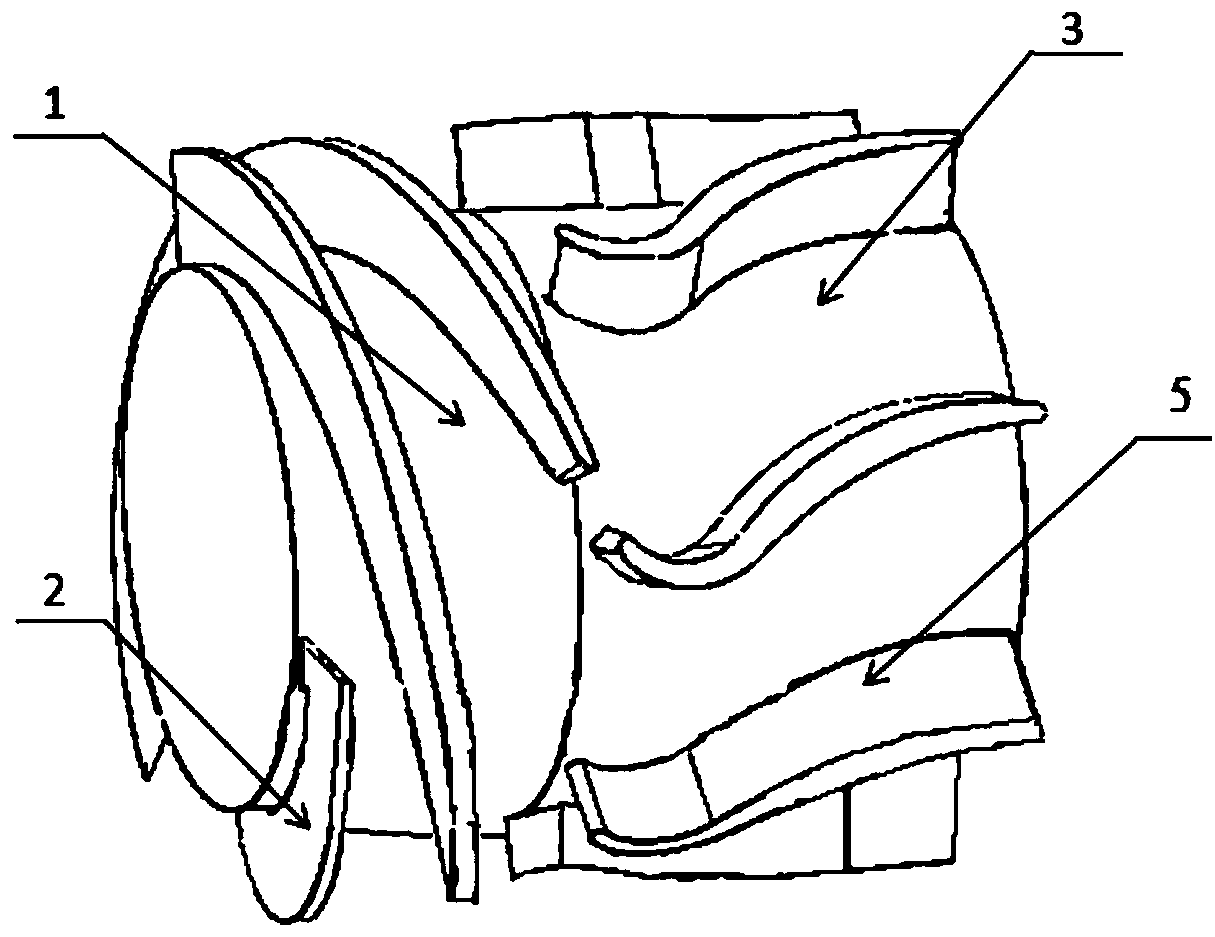

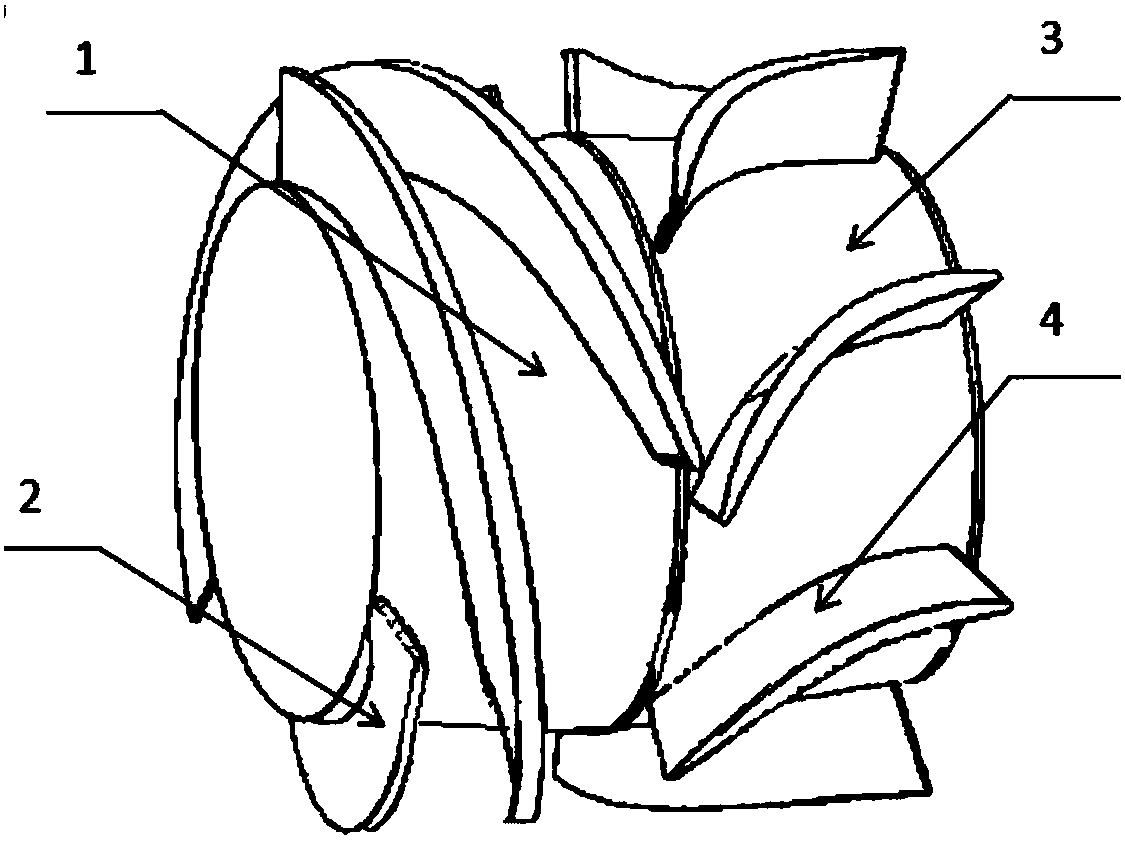

[0023] Such as figure 1 As shown, the impeller structure of the mixed transport pump includes the moving impeller 1 and its moving impeller blade 2 and the stationary impeller 3 and its stationary impeller blade 5. 2 have the same outlet direction, and the placement angle of the static impeller blade 5 outlet is 90 degrees.

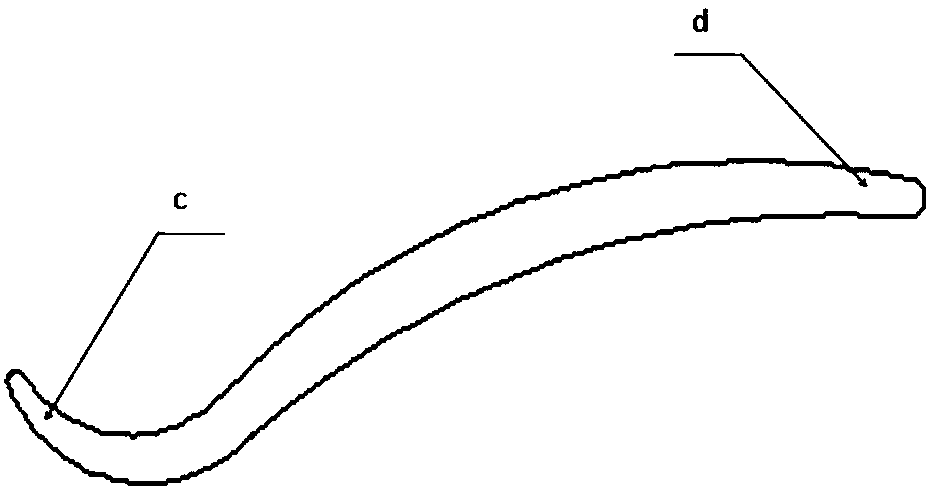

[0024] Such as figure 1 , figure 2 As shown, the bending direction of the inlet section c of the vane of the stationary impeller is opposite to that of the outlet sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com