Connecting device for electric tower operation

A connecting device and electric tower technology, applied in the direction of seat belts, life-saving equipment, etc., can solve the problems of shortening the extendable distance of seat belts, failing to find the connection point of seat belt buckles, and falling to death, so as to reduce the incidence of falling accidents , Extend the safe working range, extend the effect of the safe working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

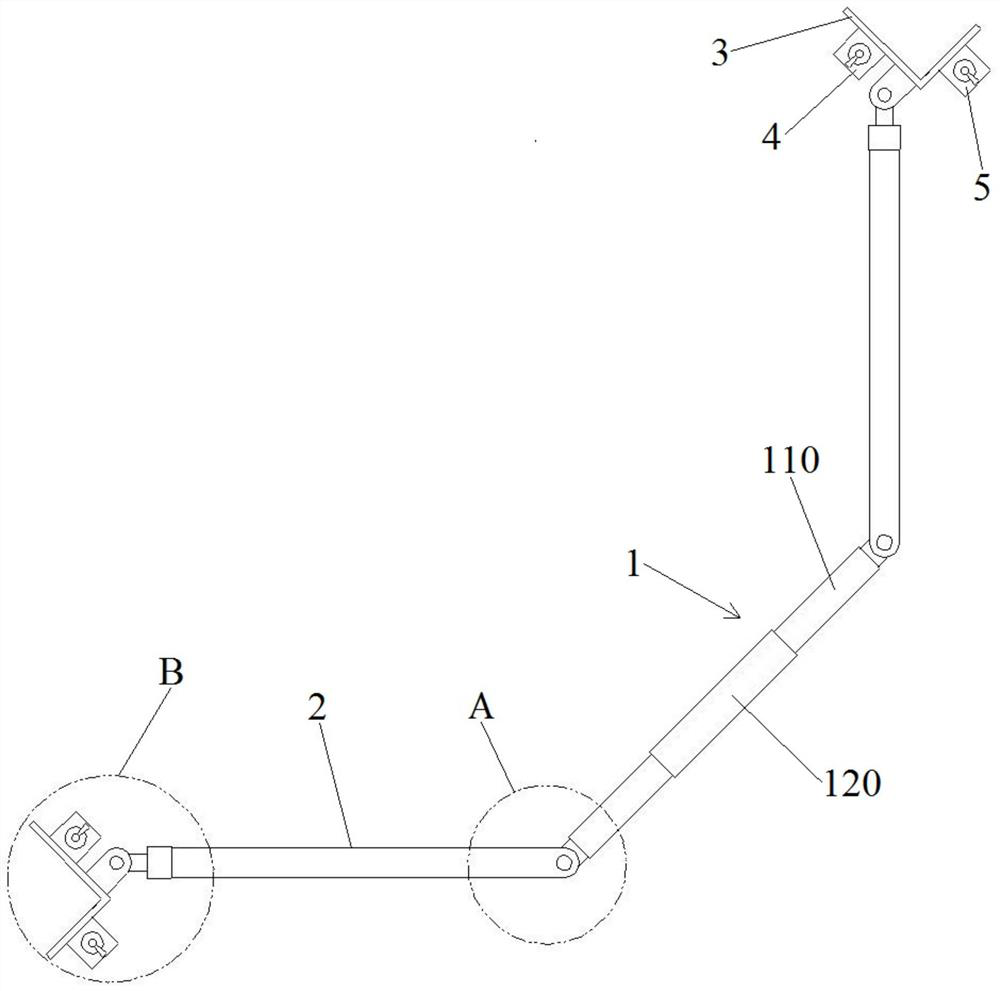

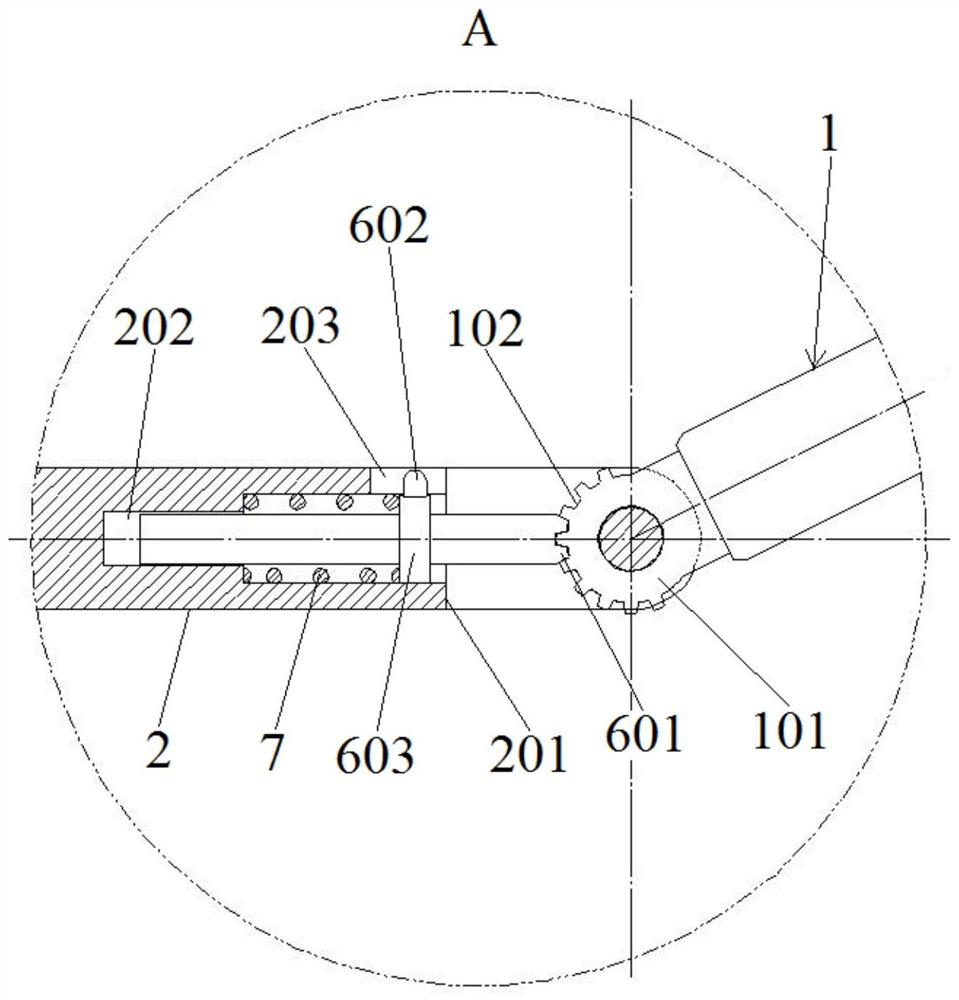

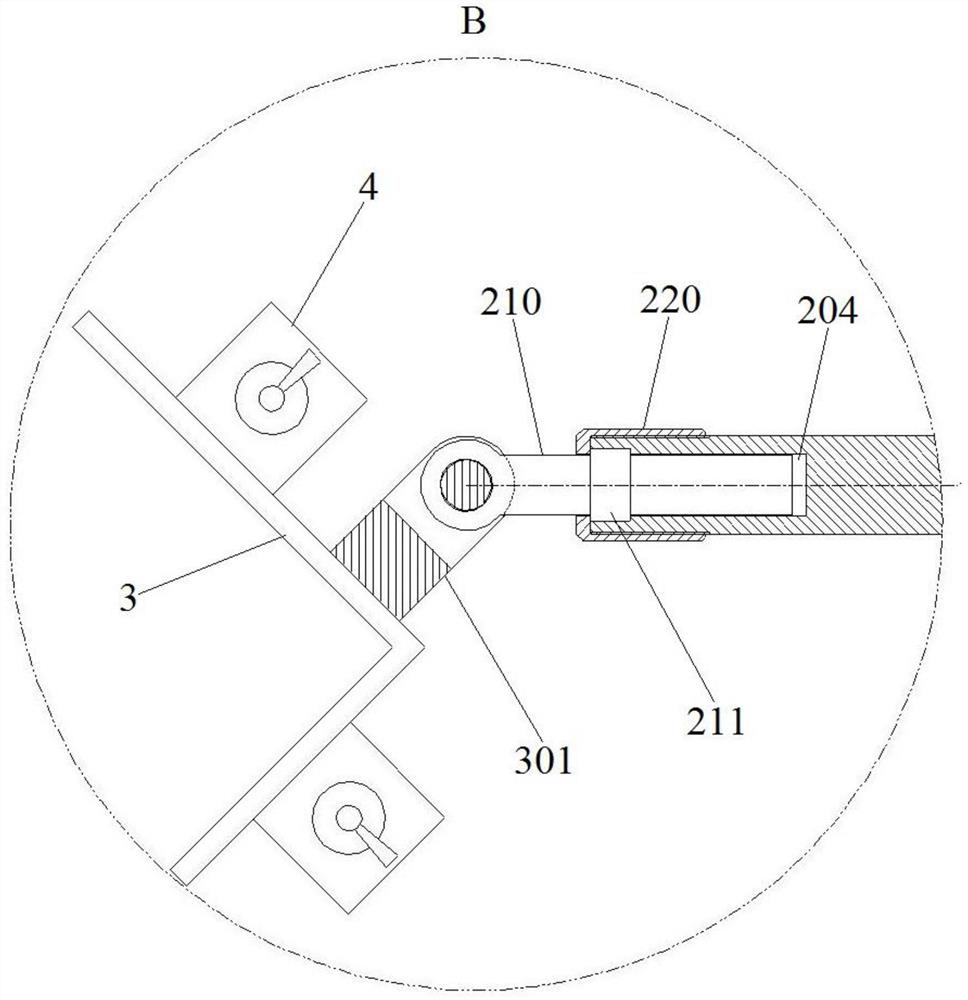

[0030] see figure 1 , figure 1 It is the connection device for electric tower operation of the present invention, comprising a middle pole 1, two side poles 2 and two angle steel sheets 3, the two ends of the middle pole 1 are respectively provided with fixed hinge joints 101; the two ends of the side poles 2 They are respectively the first end and the second end. The first end of each side bar 2 is respectively provided with a hinge groove 201, and the two side bars 2 are respectively hinged with the fixed hinge joints 101 at both ends of the middle bar 1 through the hinge groove 201. An angle positioning device is respectively arranged between the first end of the rod 2 and the end of the middle rod 1; A first magnetic suction seat 4 and a second magnetic suction seat 5 are respectively fixedly connected to the surface.

[0031] The two angle steel sheets 3 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com