An elbow joint of a mechanical arm and its action method

A technology of elbow joints and robotic arms, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of uncompactness, high cost, and complicated mechanical arm settings, and achieve low cost, convenient operation, and compact design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

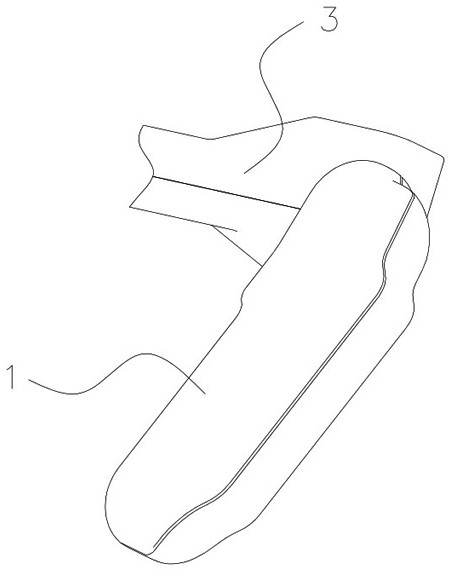

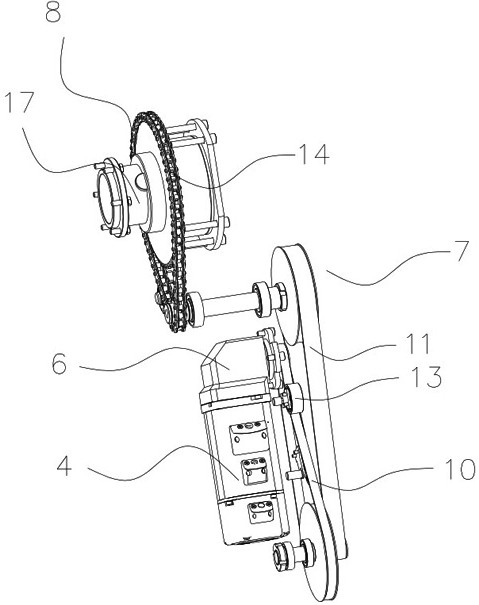

[0035] exist figure 1 , figure 2 , image 3 In the illustrated embodiment, an elbow joint of a mechanical arm includes:

[0036] Boom 1, a support arm used to realize the action of the elbow joint; a mounting seat 2 is arranged inside the big arm 1;

[0037] The forearm 3 is connected with the big arm 1 to realize the execution part of the elbow joint action;

[0038] The driving assembly 4 is arranged inside the mount 2 as a driving component for realizing the action of the elbow joint;

[0039] The transmission assembly 5 is set inside the installation seat 2 and transmits the driving force of the drive assembly 4 to the transmission part of the small arm 3; the transmission assembly 5 includes a right-angle planetary reducer 6, a belt transmission 7 and a chain transmission 8 connected in sequence; the chain The transmission 8 is connected with the forearm 3 and drives the forearm 3 to move to realize the driving of the elbow joint.

[0040] The drive assembly 4 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com