Salvage device capable of circularly collecting materials in rotary mode

A salvage device and a rotary type technology, applied in the field of water conservancy salvage devices and salvage devices, can solve the problems of unfavorable space utilization, easy to be compressed, waste of space resources, etc., and achieve the effects of increasing storage capacity, good efficiency and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

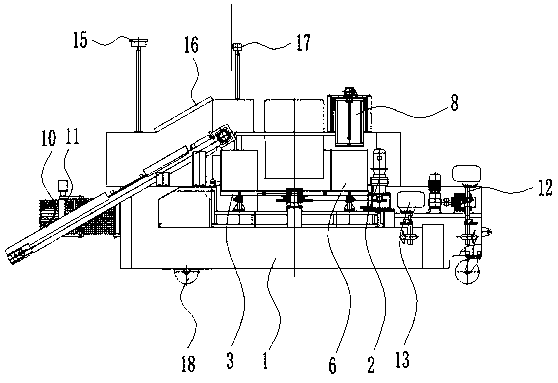

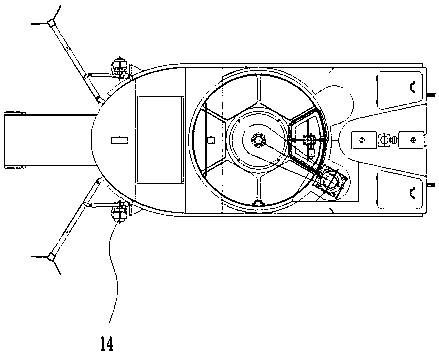

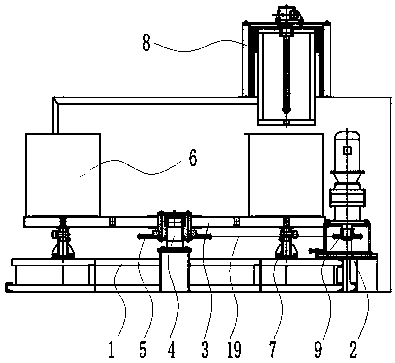

[0033] A kind of salvage device for rotary circulation receiving materials, such as figure 1 As shown, it includes a floating body 1, which is provided with a transmission mechanism 10 for salvage, on which the two sides of the front end of the transmission mechanism 10 are located, a material gathering mechanism 11 is also arranged on the floating body 1, and a rotatable turning mechanism is also provided on the floating body 1. And the first driving device 2 for driving the rotary mechanism to rotate, the rotary mechanism includes a load-bearing disc body 3, the disc body is arranged on the base through a rotatable rotating shaft 4, and the disc body 3 is also provided with At least 1 litter basket 6 for placing floating objects.

[0034] In this embodiment, the floating objects are collected from both sides to the middle through the material gathering mechanism, and then the floating objects are transported to the rotary mechanism through the transmission mechanism, and col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com