Dustbin uniform distribution weighing adjusting method

A technology of uniform distribution and adjustment method, which is used in trash cans, garbage collection, household appliances, etc. It can solve problems such as uneven garbage, and achieve the effect of strong calculation and solution accuracy, weakening crosstalk, and avoiding the reduction of equipment life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

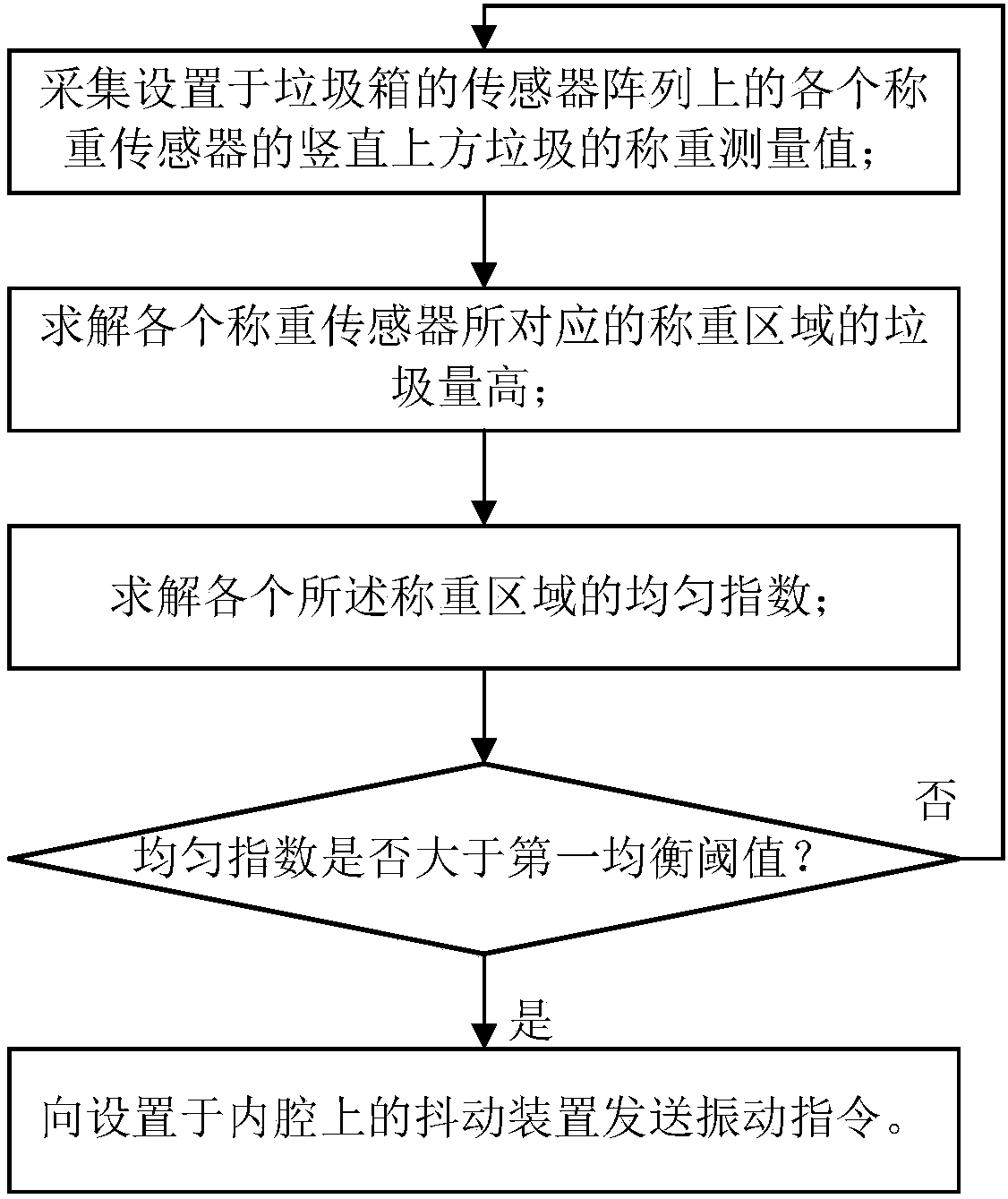

[0027] like Figure 1-4 As shown, in the first embodiment of the present invention, a method for adjusting the uniform distribution of dustbins is provided, and the method includes:

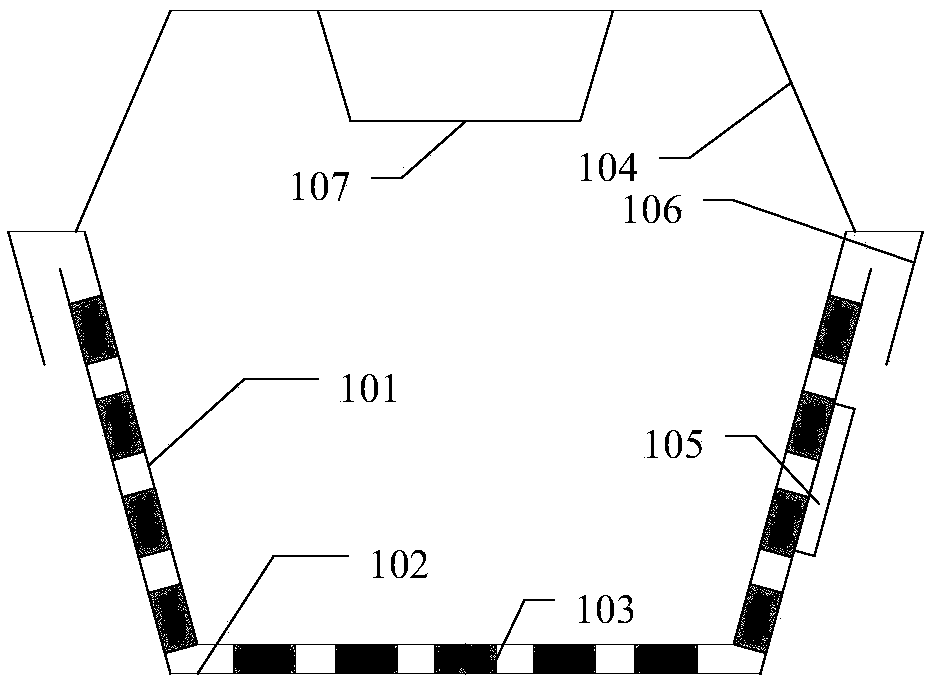

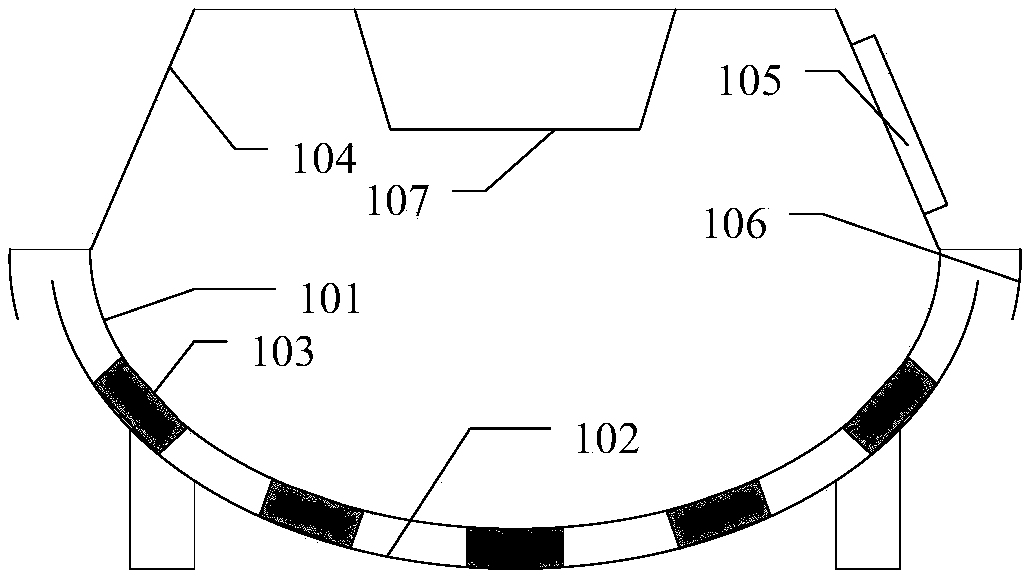

[0028] Collect the weighing measurement value T of the garbage vertically above each load cell 103 arranged on the sensor array of the dustbin i The load cell 103 is connected between the inner chamber 101 of the dustbin for storing garbage and the outer chamber 102 of the dustbin; the inner chamber 101 is a flexible material, and the load cell 103 There is a lateral gap between;

[0029] Solve the garbage volume height H of the weighing area corresponding to each of the load cells 103 i ; The amount of garbage is high H i Satisfy: Wherein, the i is the number of the load cell 103 in the sensor array, and the h i is the height of the load cell 103 relative to the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com