Construction method for boring of extra large diameter pile foundation in dangerous landform region of mountainous area

A topography, super-large diameter technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as waste of resources, failure to achieve expected results, increase construction costs, etc., to reduce difficulty and speed up manual excavation , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

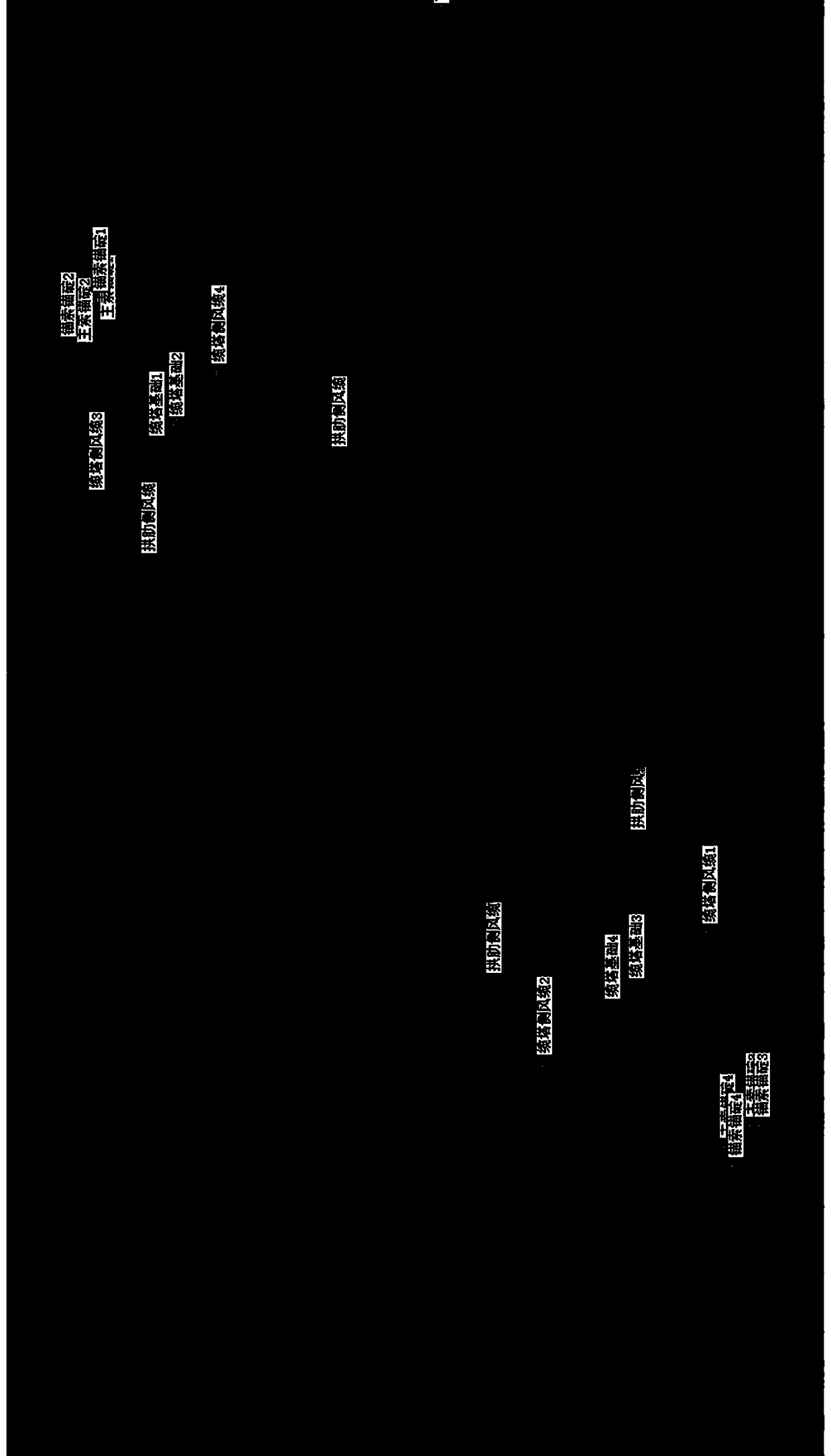

[0019] Use UAV aerial photography to obtain the image of the area to be constructed, and combine BIM technology and the digital map of the area to establish a digital map model and digital map simulation terrain for the area, and derive the actual topography of the site. According to the simulated terrain on the digital map, the amount of excavation and filling is reasonably allocated, and materials are collected locally at the filling place, and construction access roads, construction sites and slope protection operation platforms are planned and built. digital map model figure 1 , the digital map simulates the terrain to participate in figure 2 .

[0020] The construction access road provides reliable traffic conditions for small rotary drilling rigs to enter the site smoothly. Due to site limitations, the construction access road does not have the conditions for large-scale machinery to enter the site. The construction access road is 6.5m wide and laid with reinforced mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com