Turnable power head for drilling box and drilling machine

A drilling rig power head and power head technology, which is applied in the field of power heads, can solve the problems of broken anchor rods in the drill hole and low work efficiency, so as to achieve accurate hole finding and avoid inaccurate hole finding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

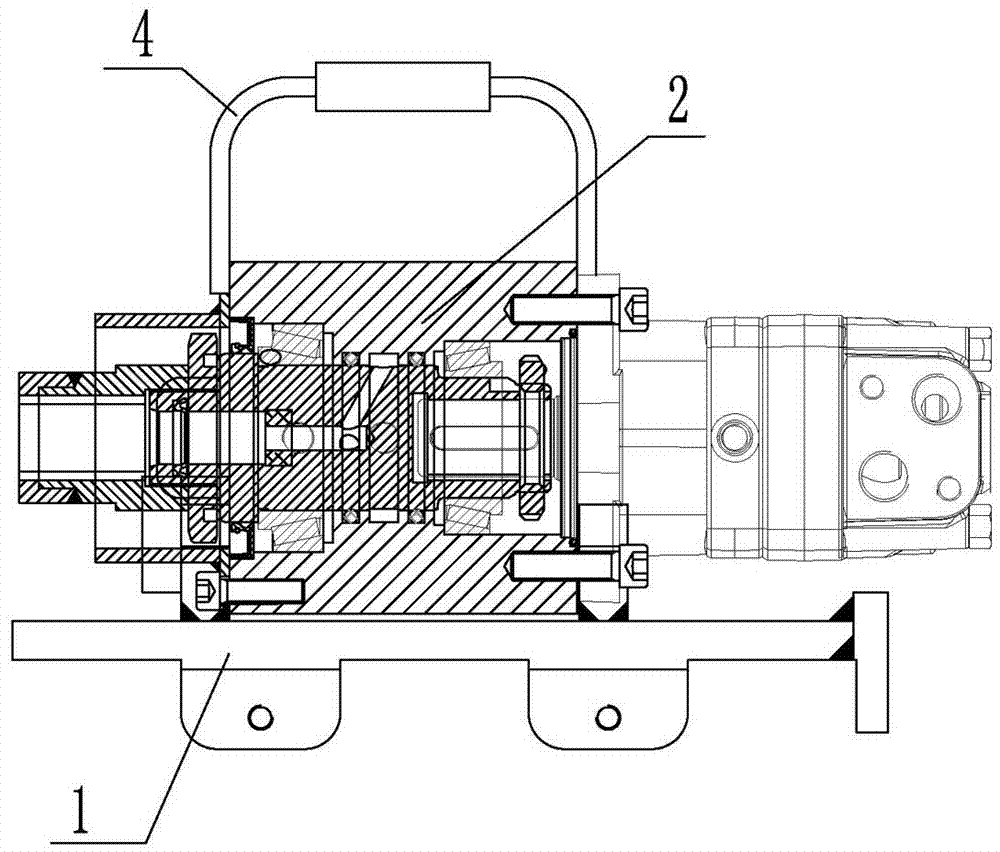

[0008] A reversible drill box drill power head, such as figure 1 , figure 2 and image 3 As shown, it includes the fixed seat 1 and the power head 2, the hinged seats 3 are respectively installed on both sides of the upper part of the fixed seat 1, and the two sides of the lower part of the power head 2 are respectively provided with mounting seats 18, and the pin holes 19 are provided on the mounting seats 18, and the pin holes 19 are fitted with The hinged shaft 5 is installed, and the hinged shaft 5 is fitted in the hinged seat 3. After one hinged shaft 5 is extracted from the hinged seat 3 and the pin hole 19, the power head 2 can rotate around the other hinged shaft 5. The fixed seat 1 is installed on the airborne hydraulic rock bolter. With this structure, after the drill rod is removed, one hinged shaft 5 can be pulled out from the hinged seat 3 and the pin hole 19, and the power head 2 can be rotated around the other hinged shaft 5 to leave the original position, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com