Dry-wet method temperature and humidity sensing probe adopting fiber grating sensors

A fiber grating and humidity sensing technology, applied in instruments, measuring devices, etc., can solve the problems of environmental sensitivity, high labor cost, and decreased accuracy of electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

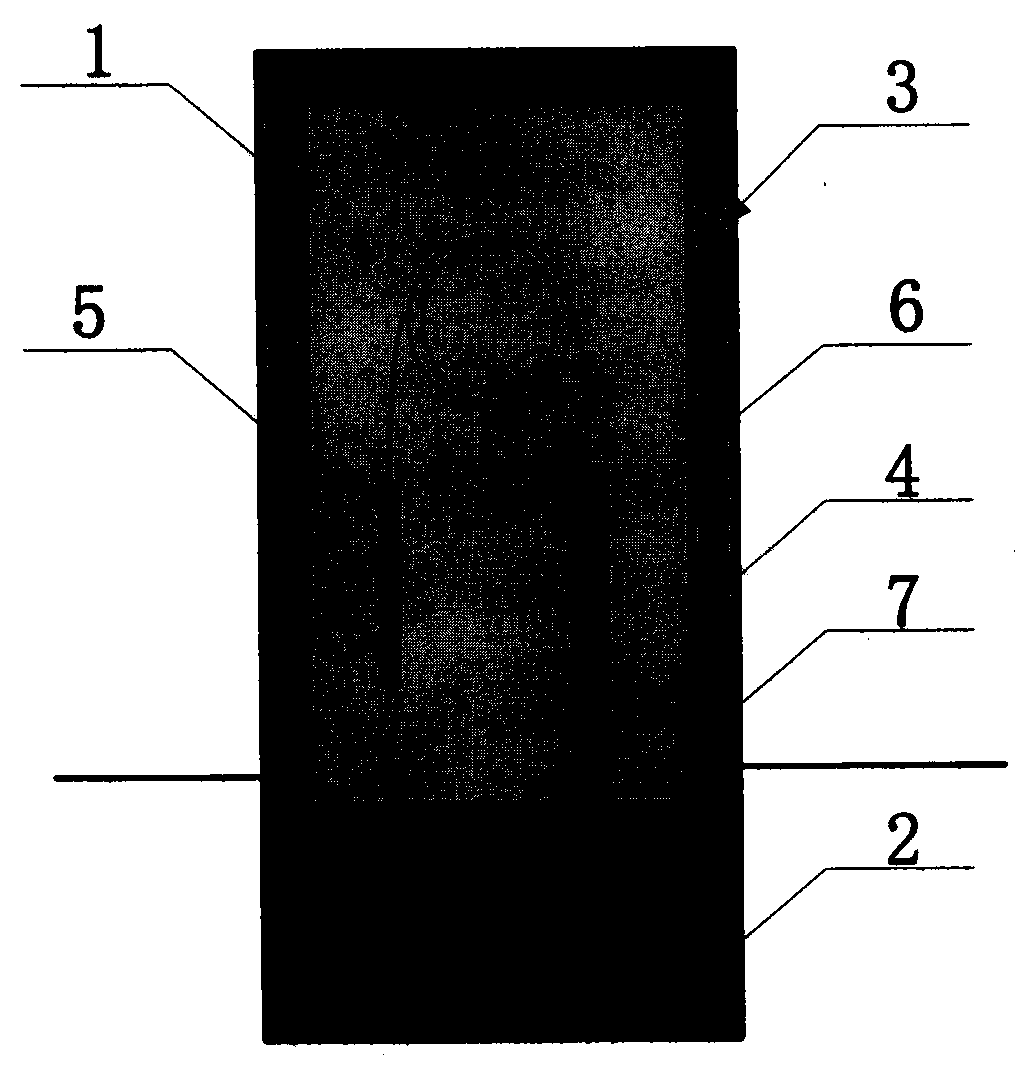

[0009] figure 1 Shows the working principle diagram of the dry and wet temperature and humidity sensing probe using the fiber grating sensor. The probe is mainly composed of a fixed base plate (1), water tank (2), outer shield (3), humidity drainage line (4), fiber grating temperature sensor (5), fiber grating humidity sensor (6), tail cable (7), etc. Partial composition. The fiber grating temperature sensor (5) is fixed on either side of the bottom plate, the fiber grating humidity sensor (6) is covered with the humidity drainage line (4) and fixed on the other side, the end of the humidity drainage line (4) is inserted into the water tank (2), The fiber grating temperature sensor (5) and the fiber grating humidity sensor (6) are connected by optical fibers, the input and output fibers of the two are led out from the hole in the middle of the pigtail cable (7), and the outer shield (3) is buckled on the fixed bottom plate (1) ) Protect the temperature and humidity sensor and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com