Steel strand bending machine

A technology of steel strands and benders, applied in the field of benders, can solve the problems of inability to protect the anti-rust paint layer, easily injure the staff, and the bending angle of the steel strands is not smooth enough, so as to achieve easy operation and good Controllability and the effect of increasing the bending speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

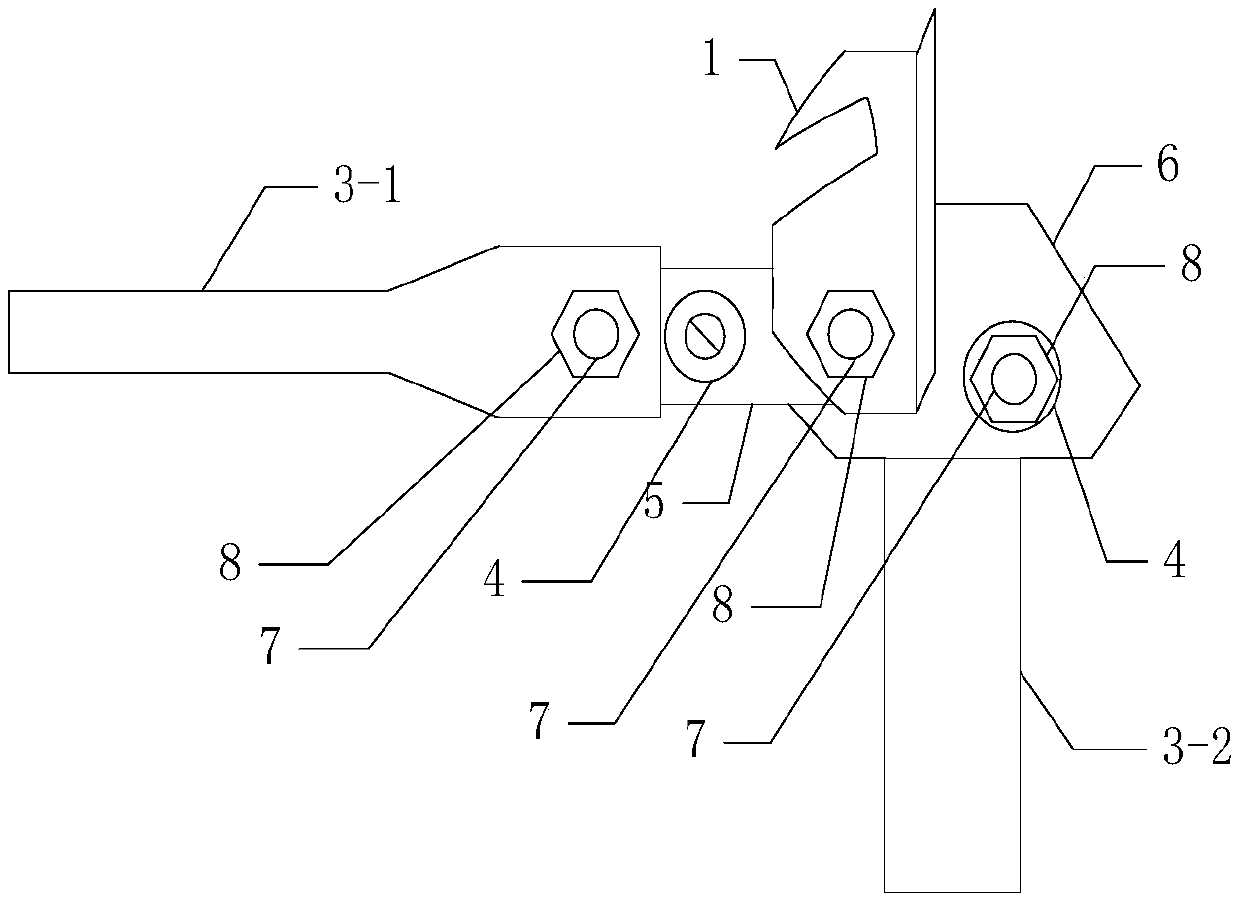

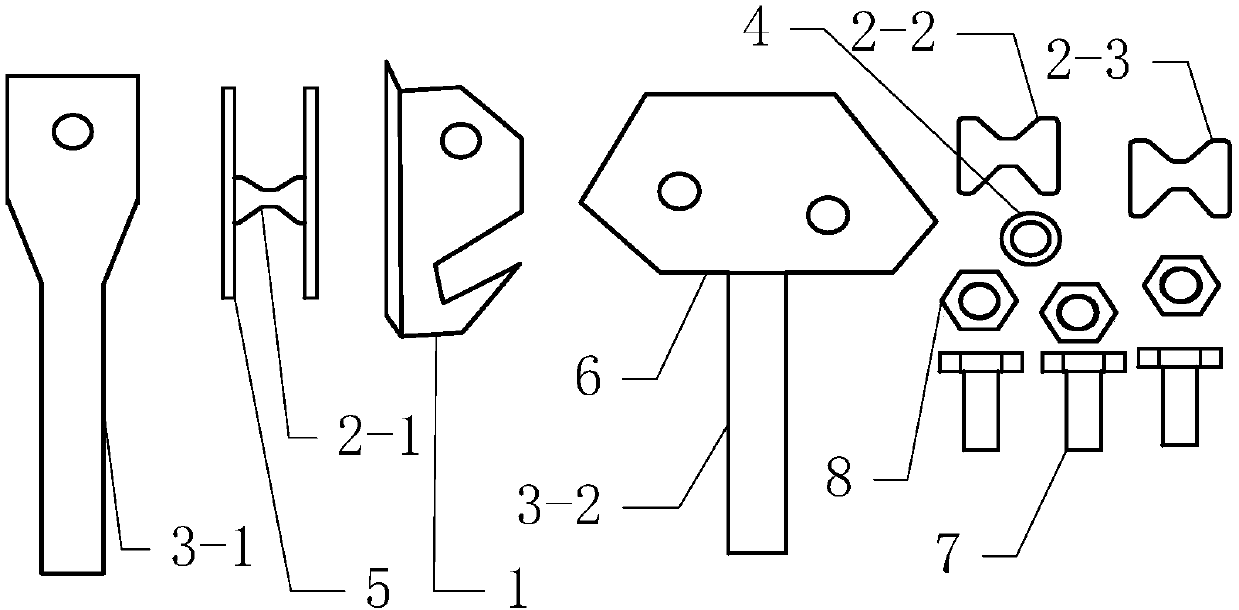

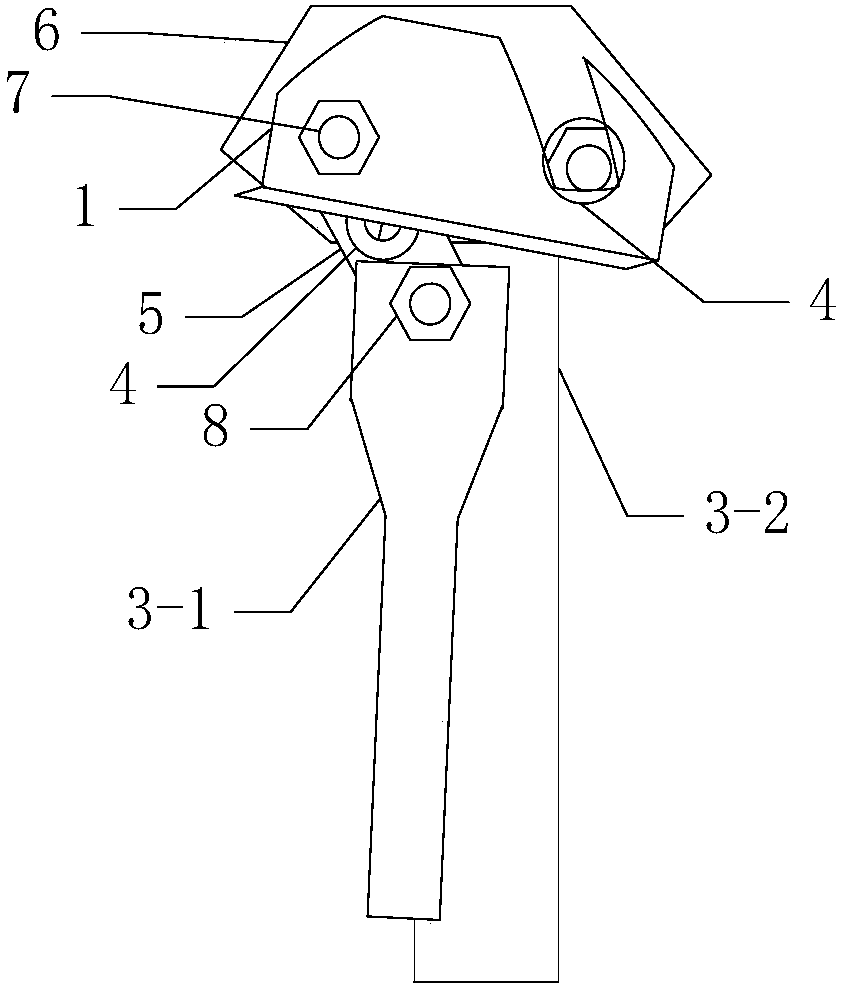

[0011] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, the steel strand bender described in this embodiment includes three pulleys 2, two handles 3 and a fixed plate 6; it is characterized in that it also includes a baffle plate 1 and n spacers 4 , two connecting plates 5, two bolts 7 and three nuts 8;

[0012] Described handle 3 is No. 1 handle 3-1 and No. 2 handle 3-2, and No. 2 handle 3-2 is fixed on the fixed plate 6; One end of two connecting plates 5 is connected with the other end of fixed plate 6 simultaneously, And two connecting plates 5 are stacked up and down, and the other end of the connecting plate 5 is connected with one end of the No. 1 handle 3-1;

[0013] Described three pulleys 2 are No. 1 pulley 2-1, No. 2 pulley 2-2 and No. 3 pulley 2-3, and No. 1 pulley 2-1 and No. 2 pulley 2-2 are installed between two connecting plates 5 Between, No. 1 pulley 2-1 is positioned at the center of two c...

specific Embodiment approach 2

[0017] Specific Embodiment 2: This embodiment further limits the steel strand bender described in Specific Embodiment 1. In this embodiment, the No. 1 handle 3-1 is a movable handle, and No. 2 handle 3-1 is a movable handle. 3-2 is a fixed handle.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment further limits the steel strand bender described in Embodiment 1. In this embodiment, the pulley 2 is a nylon pulley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com