Automatic plate clamping device

A clamping device and plate technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of construction personnel's inconvenience, construction personnel's damage, and no fixation, so as to improve the quality of work and reduce redundant manual processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

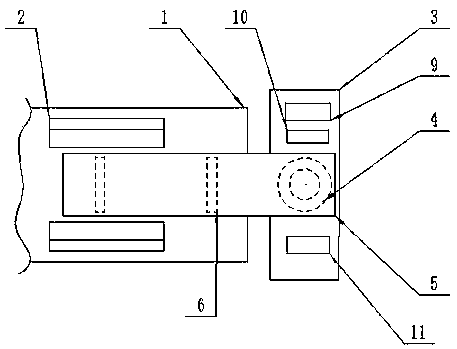

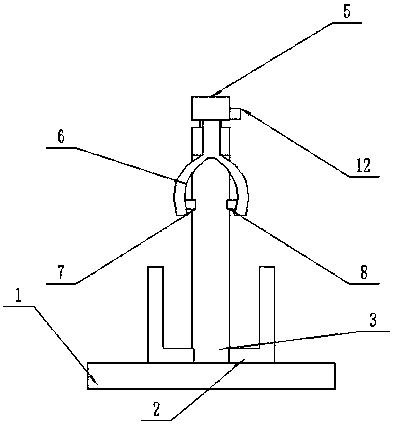

[0013] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, an automatic plate clamping device includes a sliding belt (1), and a set of opposite L-shaped plate fixing frames (2) are arranged on the sliding belt (1), and the L-shaped plate fixing frame (2) An intelligent grabbing mechanism is provided above, and the intelligent grabbing mechanism consists of a frame (3), a rotating motor (4) arranged on the upper end of the frame (3), and a swinging mechanism fixed at the rotating end of the rotating motor (4). arm (5), a group of mechanical tightening arms (6) arranged on the lower surface of the swing arm (5), and infrared receivers (7) and infrared generators ( 8) Composition, the frame (3) is provided with a controller (9), mains interface (10) and capacitive touch screen (11), the controller (9) and mains interface (10), capacitive touch screen (11) is electrically connected with the intelligent grasping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com