An oil drum handling device with a mobile platform

A mobile platform and handling device technology, applied in transportation and packaging, motor vehicles, multi-axis trolleys, etc., can solve the problems of insecurity and high labor costs for oil drum handling, achieve safe handling, fast and convenient clamping, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

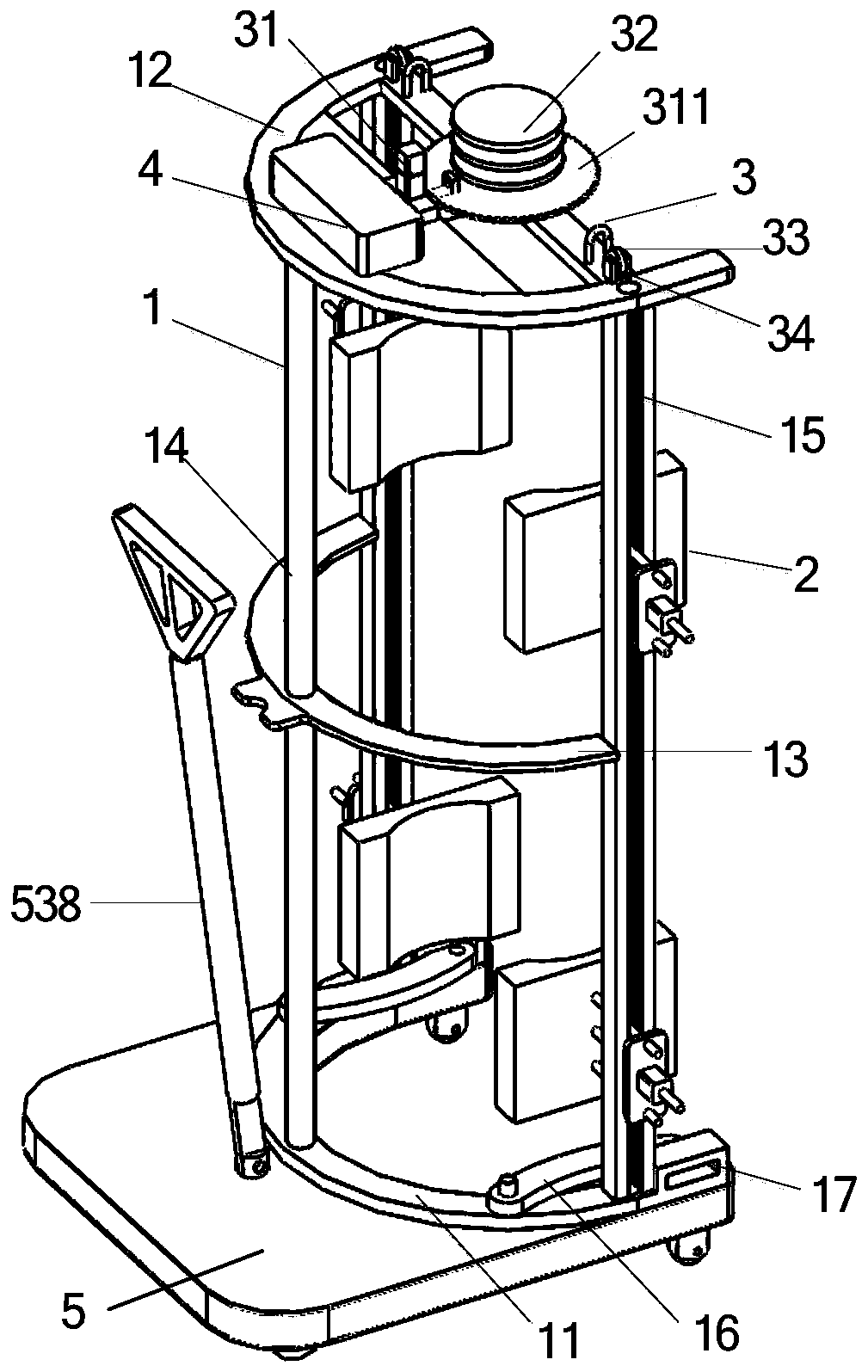

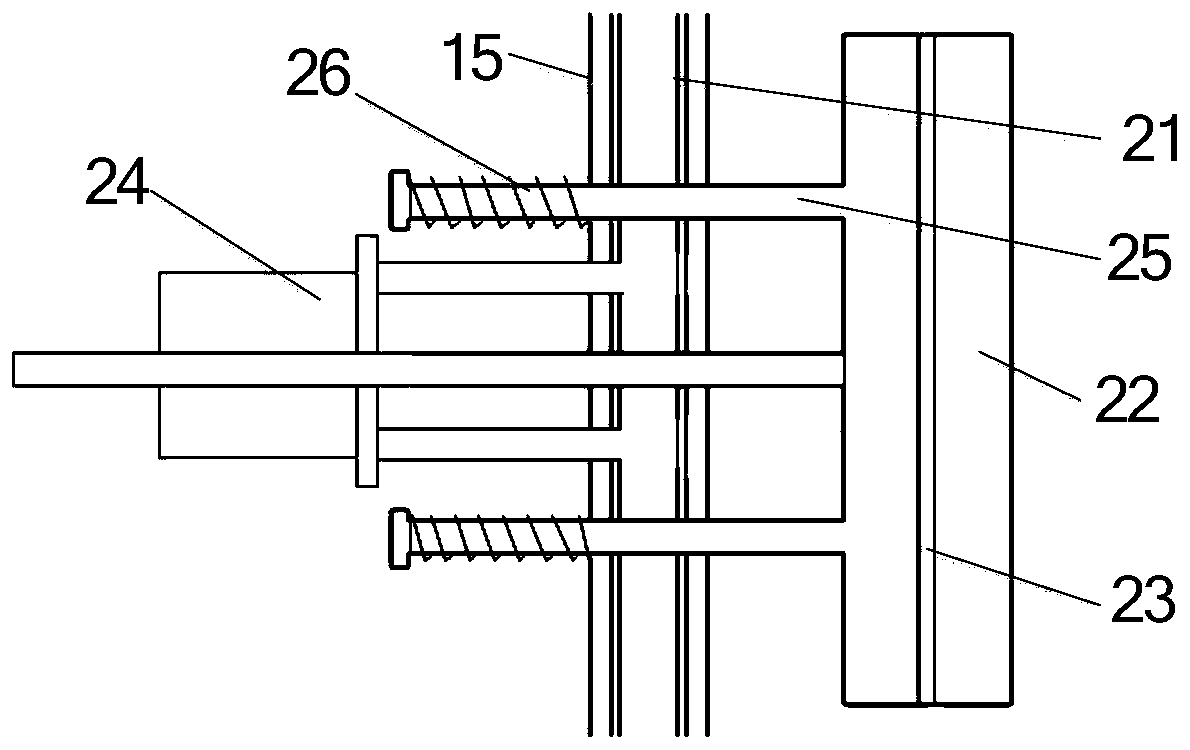

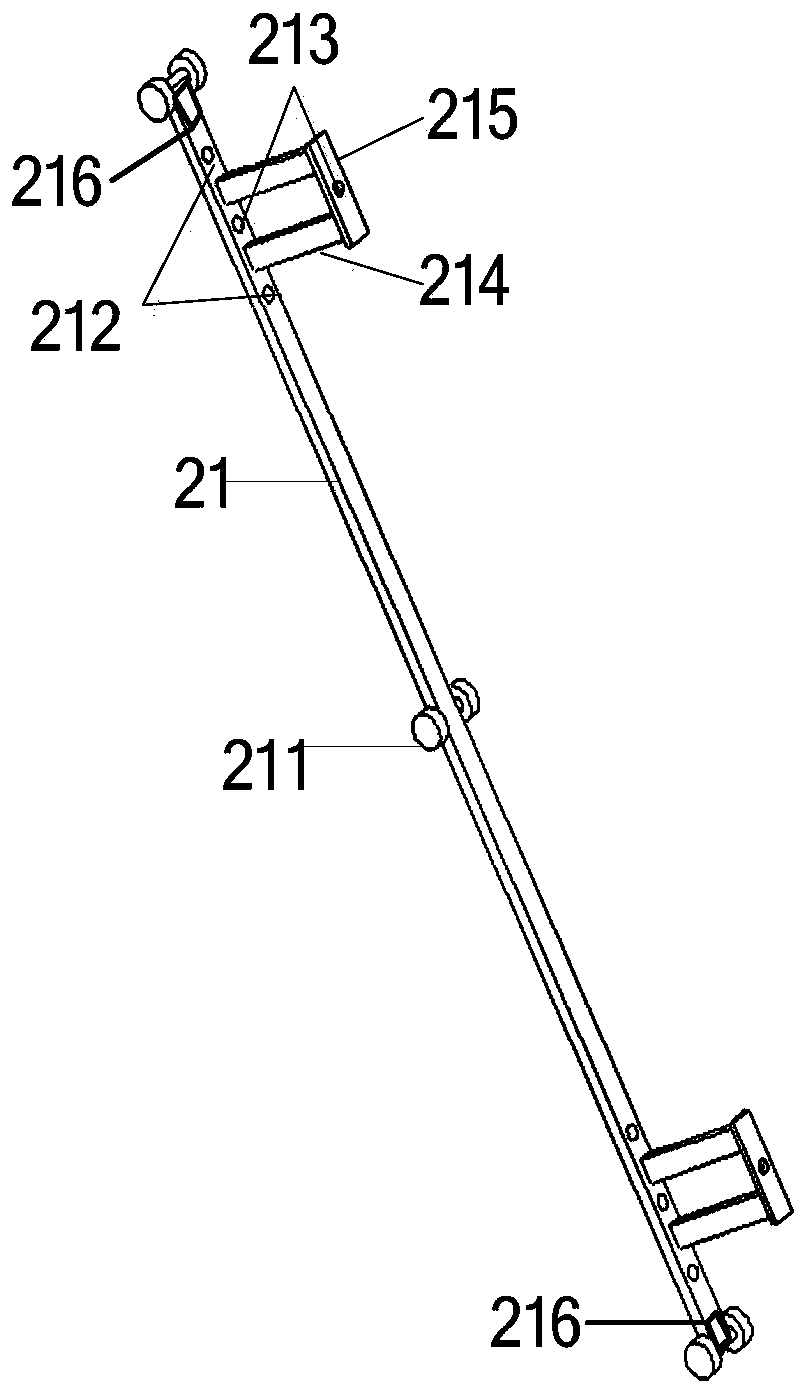

[0033] Such as figure 1As shown, the oil drum handling device includes a frame 1 , a clamping part 2 , a lifting part 3 and a moving platform 5 . The frame 1 is semi-cylindrical, and the clamping part 2 is arranged symmetrically on both sides of the frame 1. The clamping part 2 is divided into upper and lower groups. The upper end surface is used to control the one-way rotation of the lifting part 3 . , the frame 1 includes a semi-arc-shaped base plate 11 arranged at the bottom, a top plate 12 is arranged directly above the base plate 11, and three uprights 14 are arranged between the base plate 11 and the top plate 12, and the three uprights 14 are respectively located in the middle and two ends of the base plate 11, The columns 14 located at both ends of the base plate 11 are provided with guide rails 15 along the length direction of the columns, and the middle and both ends of the bottom surface of the base plate 11 are provided with self-locking wheels 18; between the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com