An electric oil drum handling device

A technology for handling devices and oil drums, which is used in transportation and packaging, motor vehicles, multi-axis trolleys, etc., can solve the problems of high labor cost and unsafe handling of oil drums, and achieve fast and convenient clamping, safe handling, and overall structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

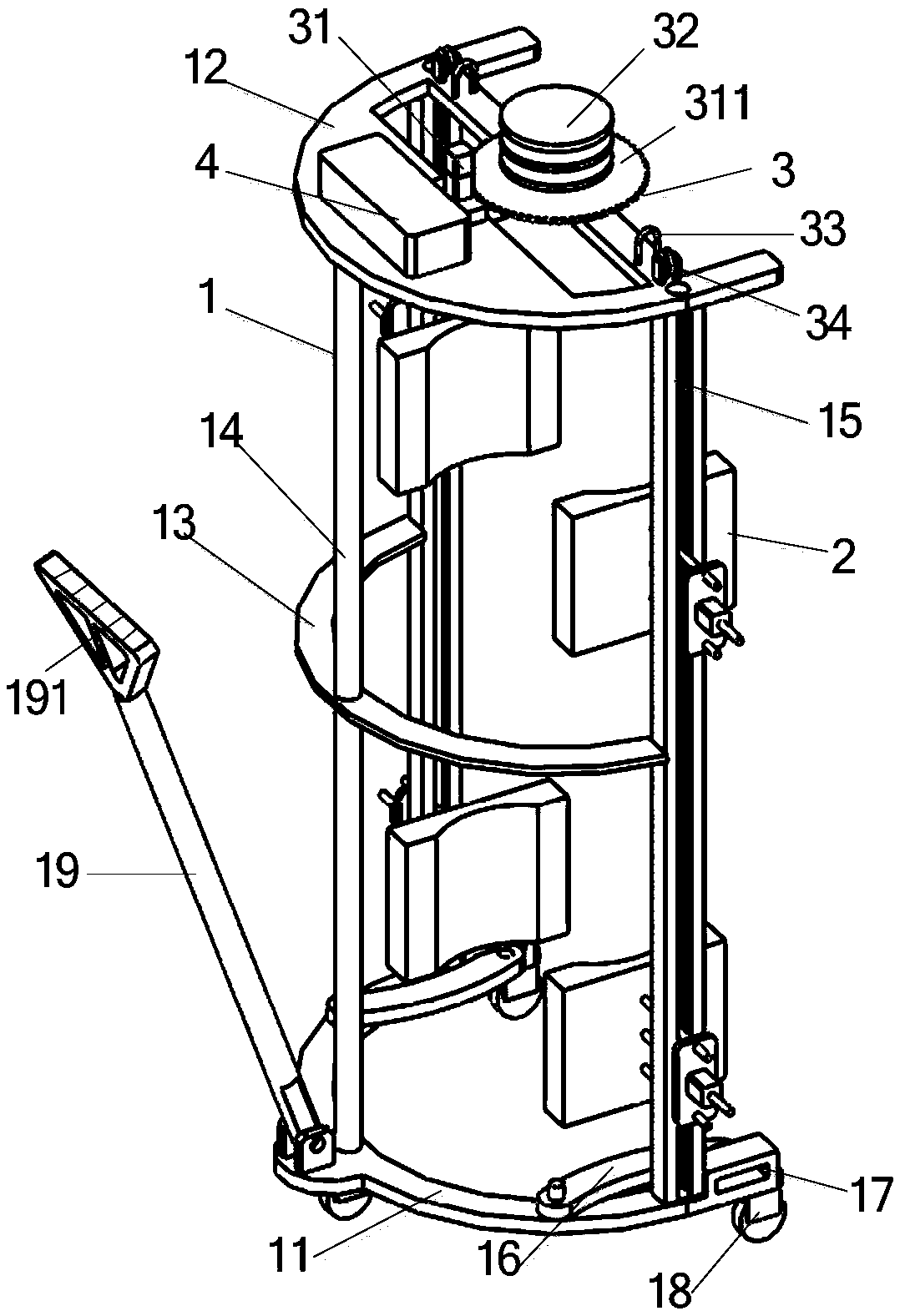

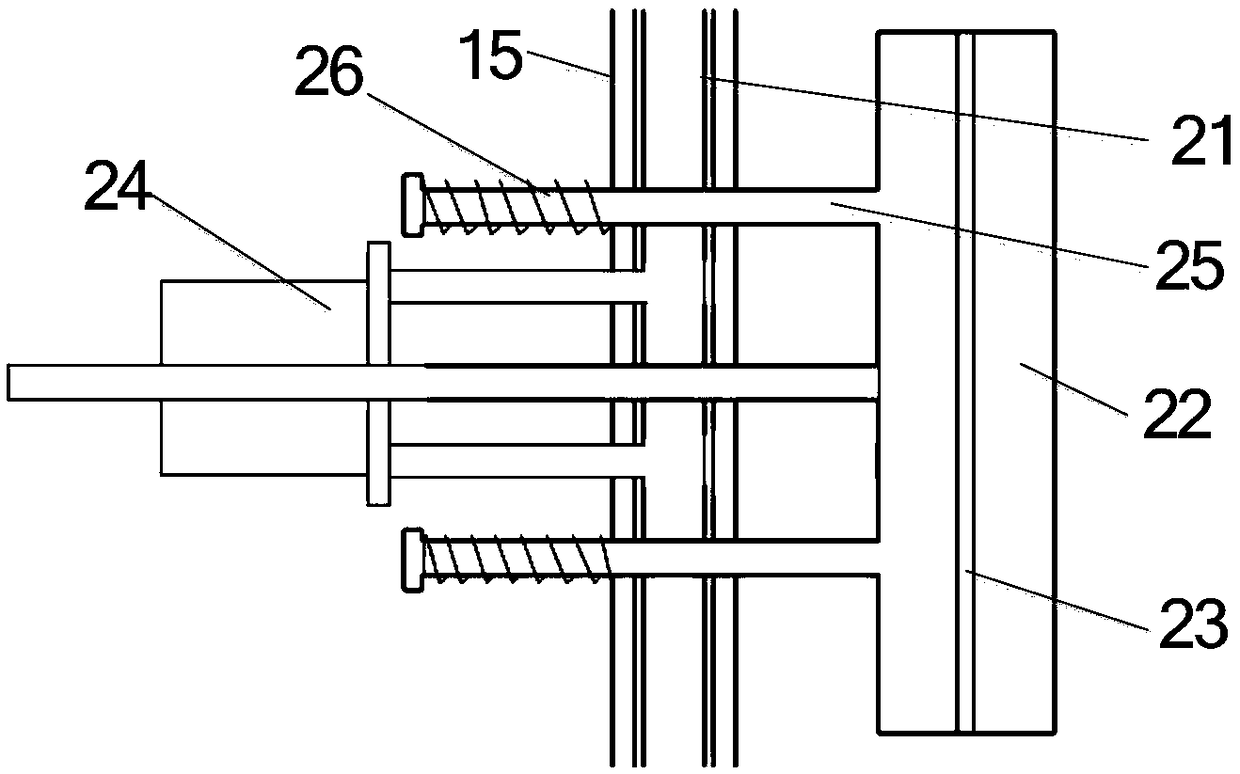

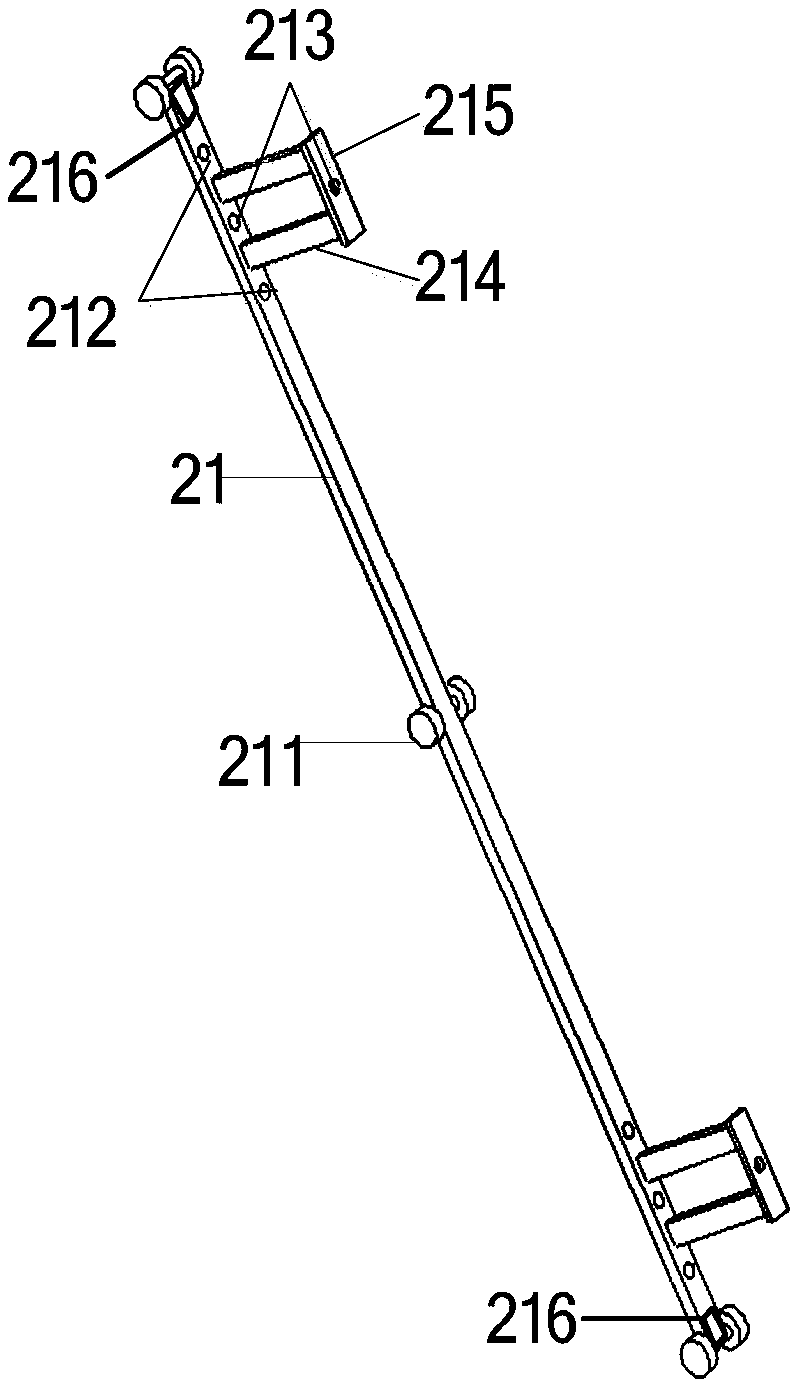

[0033] Such as figure 1 As shown, the oil drum handling device includes a frame 1 , a clamping part 2 and a lifting part 3 . The frame 1 is semi-cylindrical, the clamping part 2 is arranged symmetrically on both sides of the frame 1, the clamping part 2 is divided into upper and lower groups, the lifting part 3 is arranged on the upper end surface of the frame 1, and the rotation limiting device 4 is arranged on the The upper end surface is used to control the one-way rotation of the lifting part 3 . The frame 1 comprises a semi-arc bottom plate 11 arranged at the bottom, a top plate 12 is arranged directly above the bottom plate 11, and three uprights 14 are arranged between the bottom plate 11 and the top plate 12, and the three uprights 14 are respectively located in the middle and two ends of the bottom plate 11. The columns 14 at both ends of the bottom plate 11 are provided with guide rails 15 along the length direction of the columns, and the middle and both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com