A Laser Beam Expander Transposition Mechanism

A technology of laser beam expander and stepping motor, applied in the field of laser beam expander, can solve the problem of low positioning accuracy, achieve the best effect, improve multi-level use, and reduce the number of repeated positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

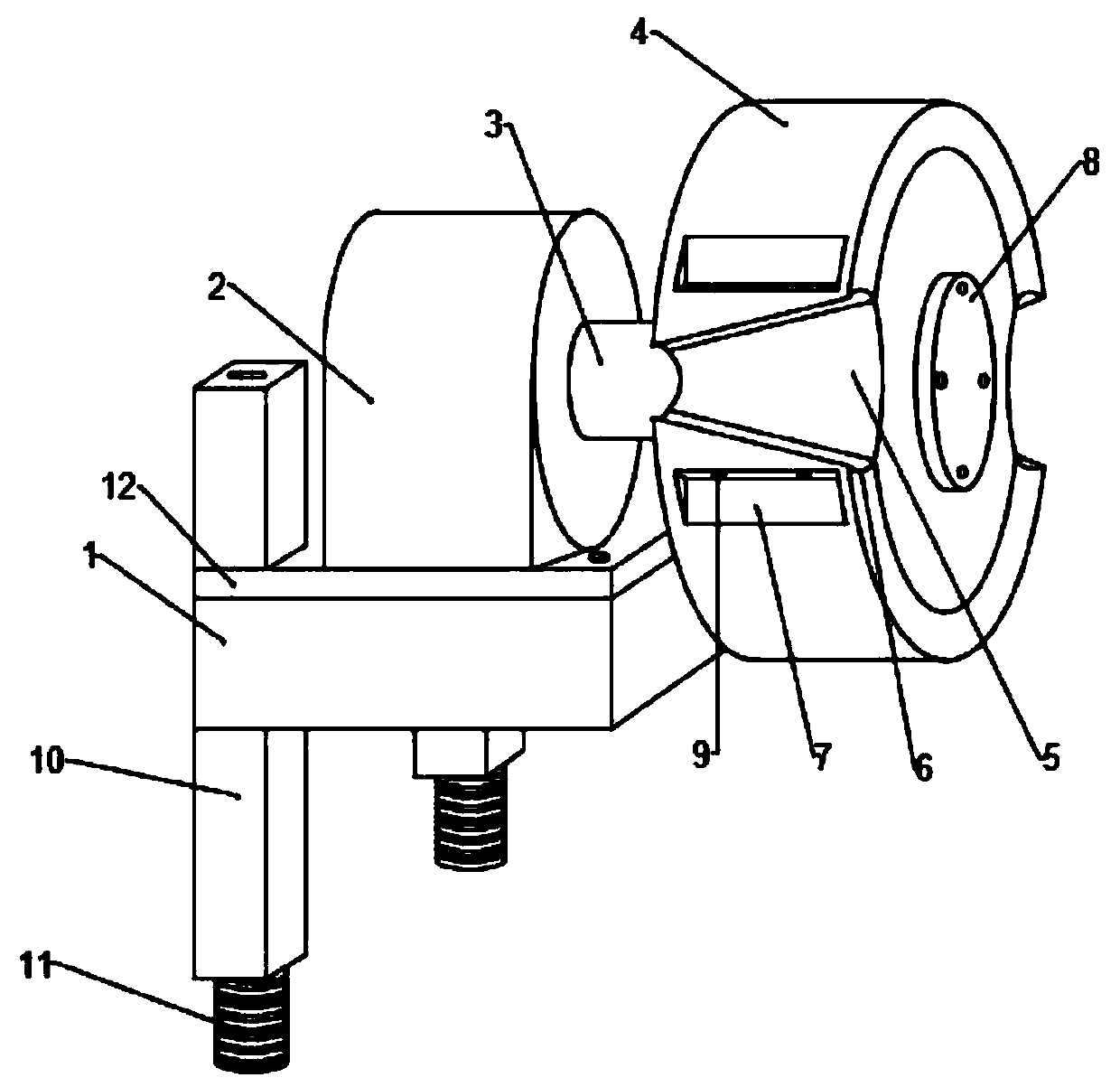

[0015] Such as figure 1 As shown, the present invention provides a technical solution, including a base 1, a cushion plate 12 is installed on the top of the base 1, and rectangular parallelepiped slide rails 10 are longitudinally installed at both ends of the left side of the base 1, so that The inside of the slide rail 10 is screwed with a lead screw 11, the top of the cushion plate 12 is equipped with a stepper motor 2, and the stepper motor 2 is connected with a transposition disc 4 through a coupling 3, and the A splined connection is adopted between the shaft coupling 3 and the transposition disc 4, and the main shaft of the coupling 3 traverses the transposition disc 4 to be connected with a disc-shaped shaft disc fixture 8, and the shaft disc fixation part 8 is fixed on the right side of the transposition disc 4 by screws, and the front and rear sides of the transposition disc 4 are provided with a trapezoidal mirror-expanding assembly groove 5, and the groove walls on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com