Quick die replacing device for prefabricated member hole and using method of quick die replacing device

A prefabricated and fast technology, applied in the directions of mold separation devices, mold fixing devices, manufacturing tools, etc., can solve the problems of not being able to achieve rapid disassembly and assembly stability at the same time, unfavorable rapid mold change and saving production costs, and cumbersome fixing of side molds. , to achieve the effect of being conducive to integrity and cleaning work, good fixing effect, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

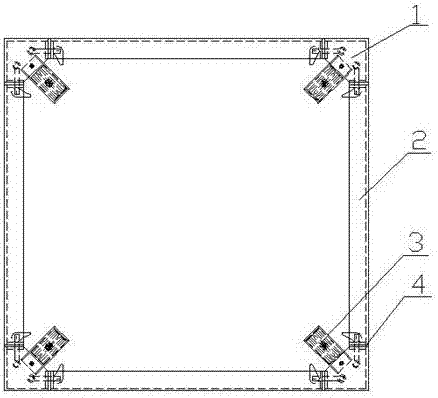

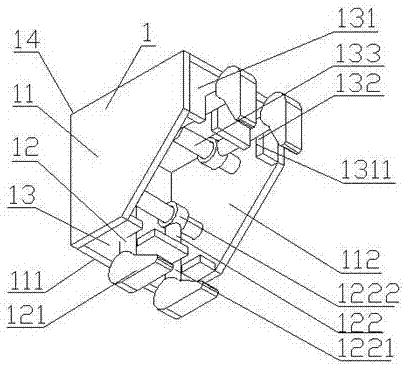

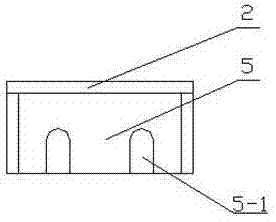

[0027] As shown in the attached figure: a quick mold change device for the opening of prefabricated parts, including side molds 2, the corner formed by two adjacent side molds 2 is connected and fixed by a quick buckle mechanism 1, and the quick buckle mechanism 1 is fixed on the table by a magnetic box 3 On the vehicle surface, the side molds 2 and the quick release mechanism 1 are arranged alternately to form a closed hole formwork structure. The end of the side mold 2 is provided with a connecting part 5 that is used in conjunction with the quick release mechanism 1. Between the quick release mechanism 1 and the connection part 5 Detachable connection.

[0028] The quick buckle structure 1 includes a housing 11, two sets of limiting mechanisms 13 installed in the housing 11 and two sets of fixing mechanisms 12. One end of the fixing mechanism 12 is connected to the limiting mechanism 13, and the other end extends out of the housing 11 for connection. The side mold 2 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com