Front Service Adaptation and Fault Diagnosis Device for Industrial Cyber-Physical Systems

A technology of fault diagnosis device and physical system, applied in the field of industrial information physical interconnection, can solve problems such as poor versatility, inability to perform statistical analysis of data, model construction and optimization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

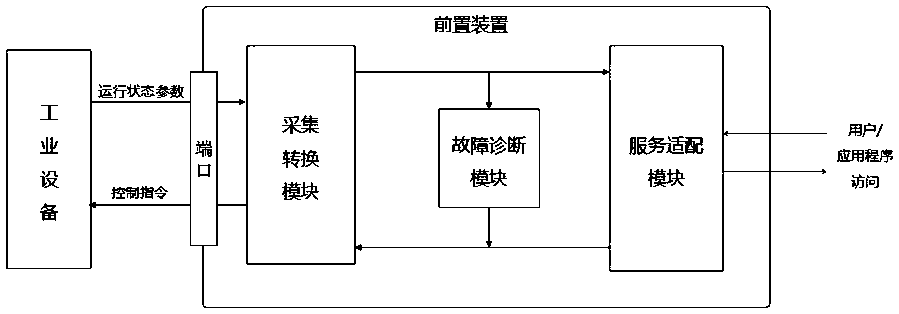

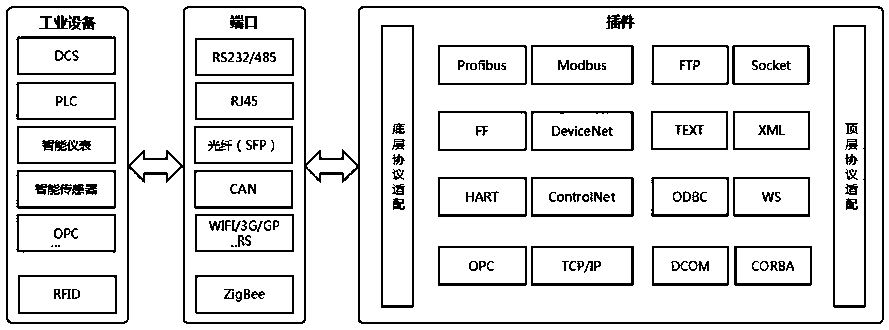

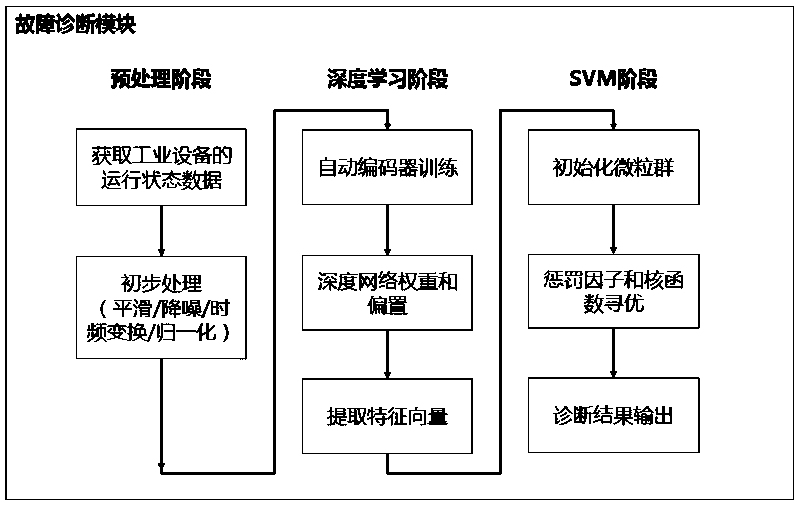

[0029] The change of operating state parameters of industrial equipment is a reliable basis for fault diagnosis. However, real-time data is unstable and unpredictable, and general embedded industrial control equipment has limited computing power and cannot complete fault model construction and real-time classification. For this reason, this embodiment designs a cyber-physical system interconnection terminal (pre-device) based on the x86 architecture, which is used to collect the operating status parameters of industrial equipment, perform real-time analysis and prediction of operating failures, and effectively adjust the work of industrial equipment. State, not only enables the front-end device of this embodiment to have the function of fault self-diagnosis, but also can convert the data command of the equipment layer into the recognizable serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com