Fast air drying-type LCD screen automatic cleaning equipment

A technology for cleaning equipment and liquid crystals, applied in lighting and heating equipment, drying, dryers, etc., and can solve the problems of uneven distribution of waterproof materials, high labor intensity of liquid crystal screens, and infiltration of water into liquid crystal equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

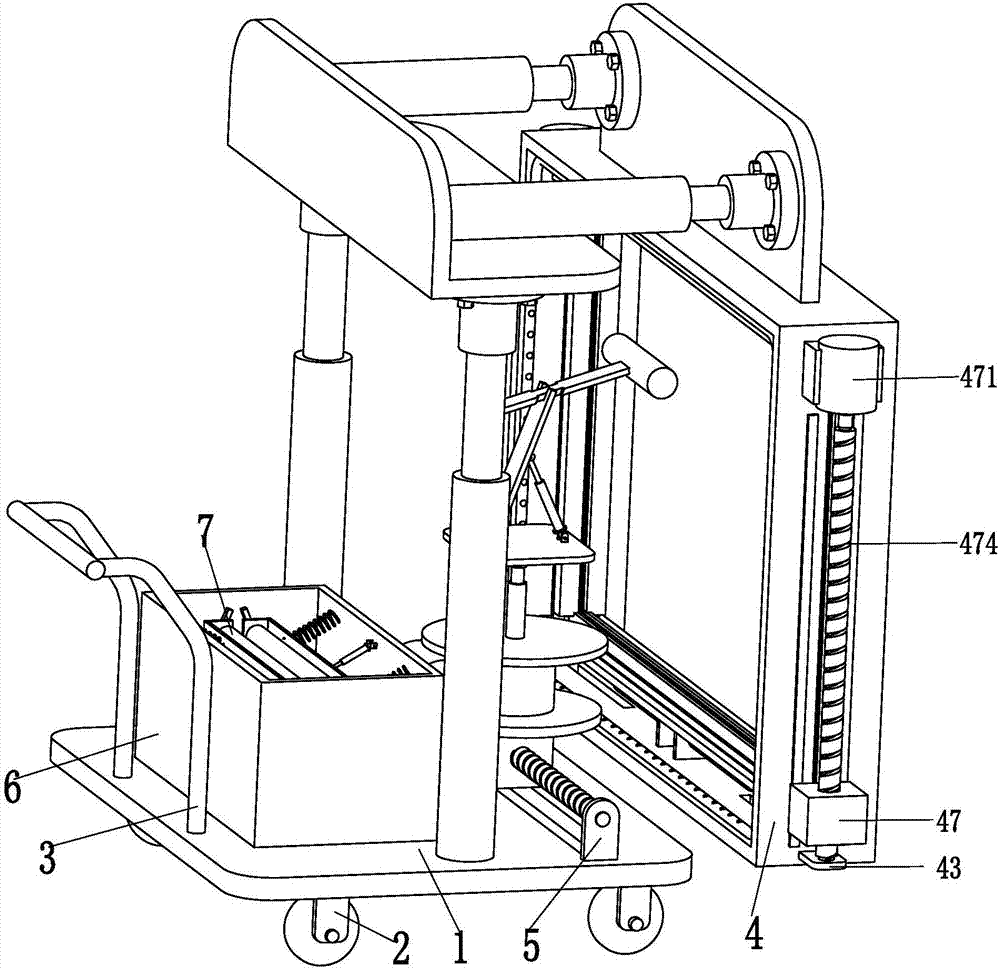

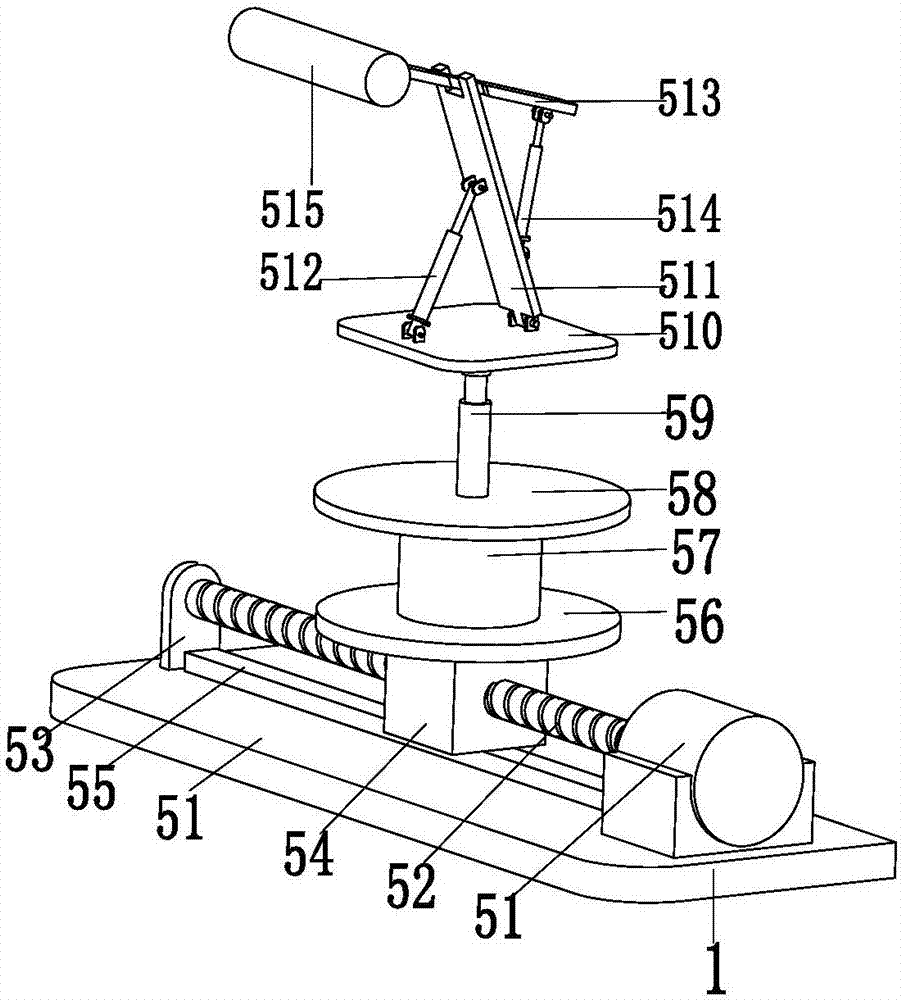

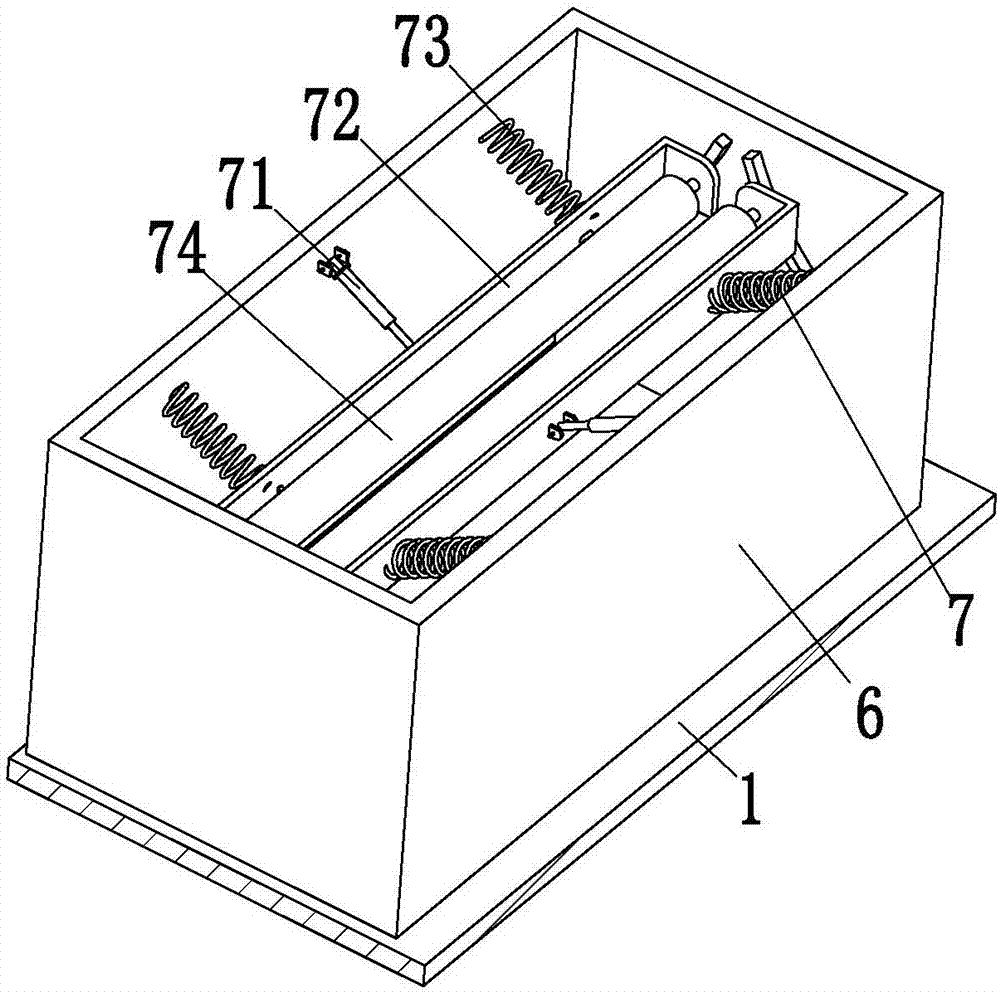

[0025] Such as Figure 1 to Figure 5 Shown, a kind of fast air-drying type LCD liquid crystal screen automatic cleaning equipment comprises base plate 1, and the lower end of base plate 1 is symmetrically installed with four universal wheels 2, and four universal wheels 2 can assist the present invention to move, and the rear end of base plate 1 Handlebar 3 is installed, and handrail 3 is convenient for staff to promote the present invention, and waterproof isolating device 4 is installed on base plate 1, and waterproof isolating device 4 can play the effect of waterproof isolation, and the front end of base plate is equipped with wiping device 5, and wiping device 5 The liquid crystal screen can be wiped. A water tank 6 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com