Oil tank with oil baffle

A technology of oil baffles and fuel tanks, which is applied to the layout combined with the fuel supply of internal combustion engines, power devices, transportation and packaging, etc. It can solve the problems of brake vacuum booster failure, engine misfire, and engine inoperability, etc., so as to improve the clogging effect , Reduce scrolling noise and increase scrolling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

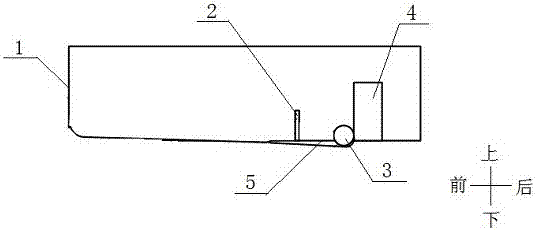

[0020] see Figure 1 to Figure 4 The shown fuel tank with the oil baffle includes a fuel tank 1, an oil baffle 2 and a small ball 3, a fuel pump 4 is arranged at the rear of the fuel tank, and the oil baffle 2 is close to the front side of the fuel pump 4 and runs through the fuel tank 1 are arranged on the left and right sides, the height of the oil baffle 2 is less than or equal to the height of the alarm liquid level of the fuel tank 1, the lower side of the oil baffle 2 is in close contact with the bottom of the fuel tank 1 and a through gap is provided, and the through gap is set at In the middle part of the lower side of the oil baffle 2, the oil baffle 2 is in the shape of a "several" and its opening faces away from the fuel pump 4, which is conducive to the return of the remaining oil at the front of the fuel tank 1 and makes it difficult for the remaining oi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap