Cooperation robot for vehicle production system and method for controlling the same

A production system and production method technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems such as increased operator load, difficulty in sharing multiple vehicle types, difficult position control, etc., to prevent shaking , Improve work stability and accuracy, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

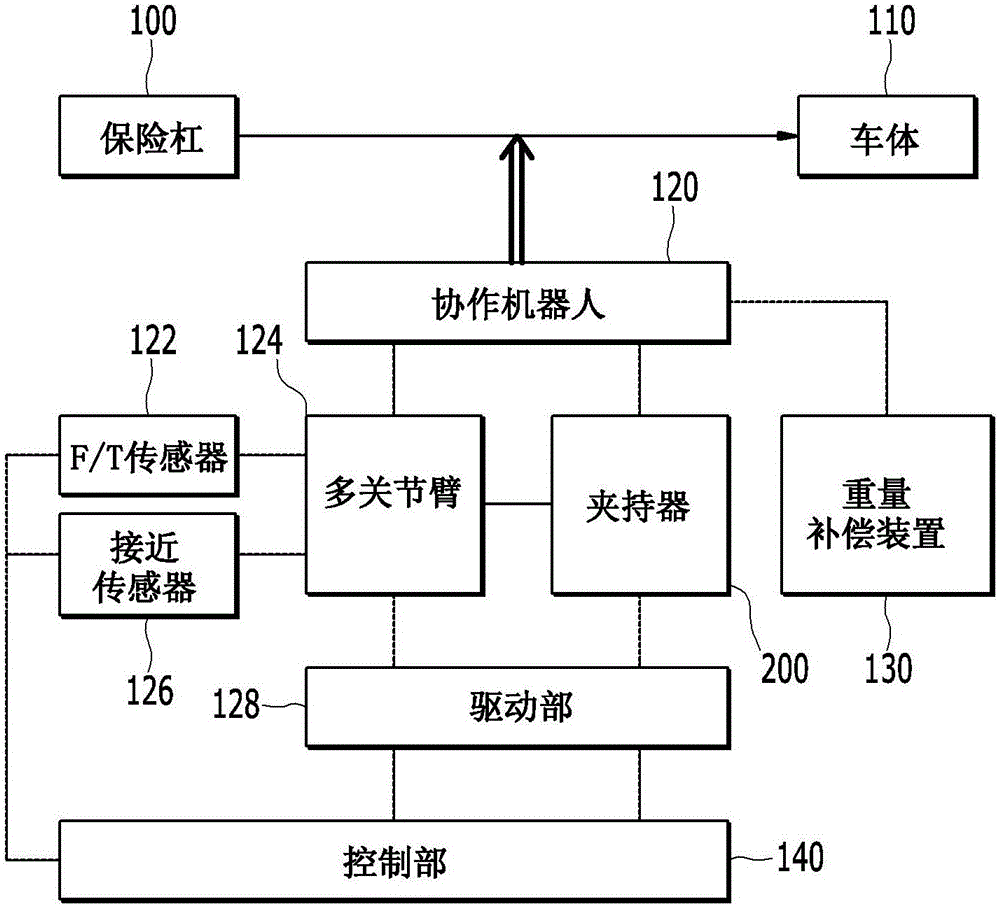

[0046] figure 1 It is a schematic configuration diagram of a vehicle production system using a collaborative robot according to an embodiment of the present invention.

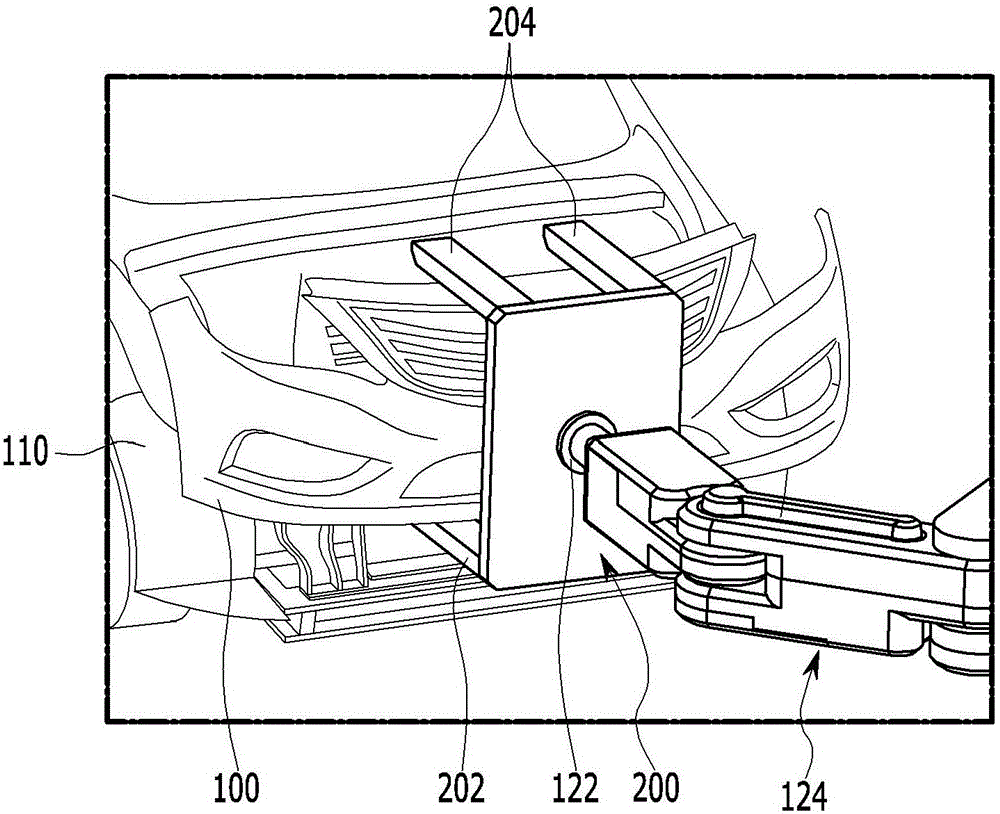

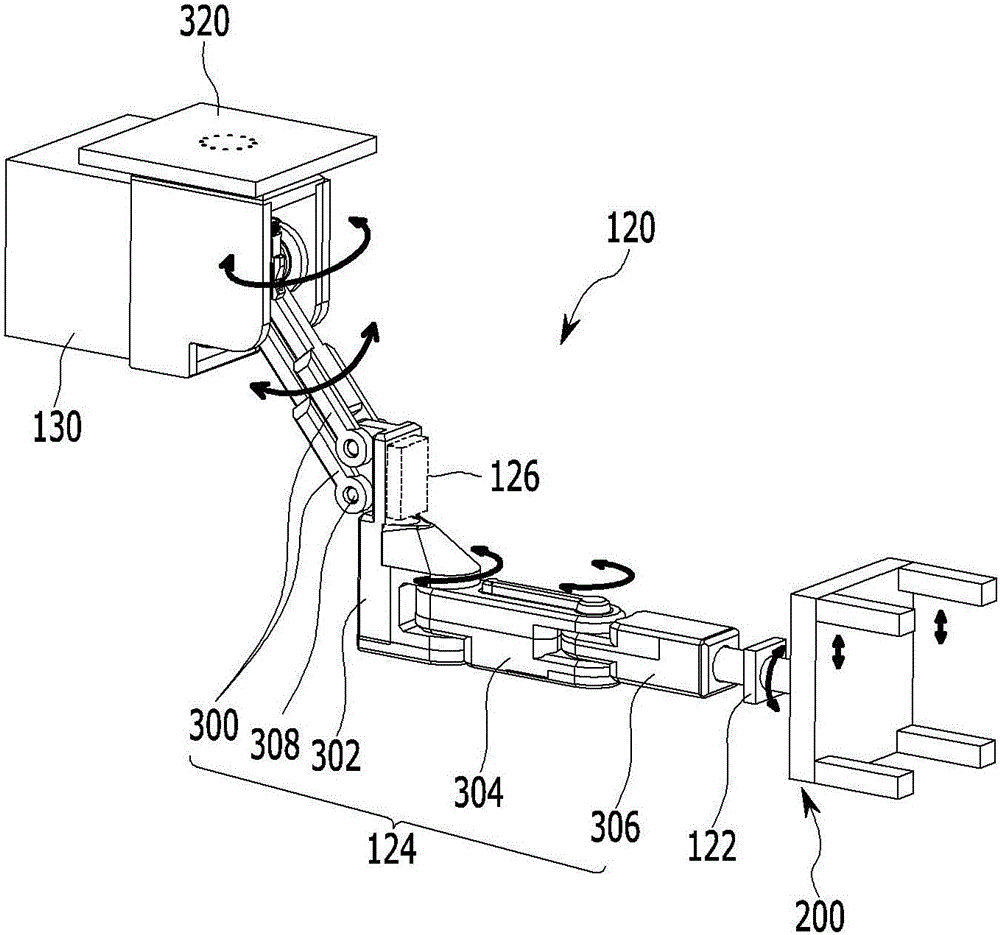

[0047] refer to figure 1 , the vehicle production system using a collaborative robot includes: a bumper 100, a car body 110, and a collaborative robot 120, and the collaborative robot 120 includes a multi-joint arm 124, a gripper 200, a weight compensation device 130, an F / T sensor 122, a proximity sensor 126 , a drive unit 128 and a control unit 140 .

[0048] The gripper 200 is mounted on one end of the multi-joint arm 124, and the drive unit 128 changes the position and rotation position of the gripper 200 in three-dimensional space through the multi-joint arm 124, and drives the gripper. The tool 200 is used to grab the above-mentioned bumper 100 .

[0049] The F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com