Automatic material sorting machine for testing charge and discharge and dormancy and operating method thereof

A charging and discharging, automatic technology, applied in the field of automatic testing and sorting equipment, to achieve the effect of easy industrialization, high degree of integration, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

[0025] Aiming at the problem of low efficiency of traditional manual testing and sorting, the designer of the present invention proposes an automatic sorting machine for charging, discharging and dormancy testing through creative research and innovation, and further provides an operation method of the device. Therefore, an effective technical solution is provided for the inspection of good products and the sorting of defective products for existing energy storage devices.

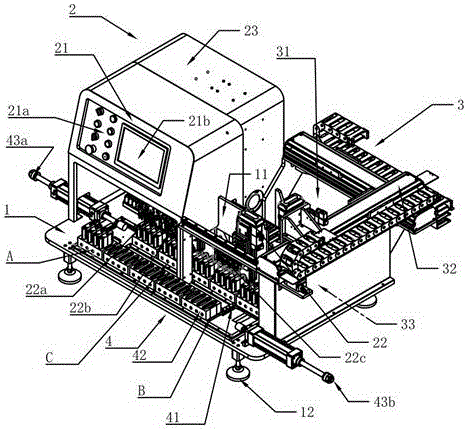

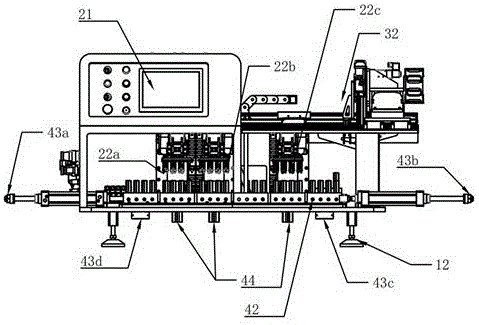

[0026] Such as figure 1 with figure 2 The three-dimensional structure sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com