Construction method of subway slab track bed

A slab ballast bed and construction method technology, applied to roads, tracks, ballast layers, etc., can solve the problems of weak quality control means, poor construction operation environment, high labor intensity, etc., and achieve high concrete transportation efficiency and good construction operation environment , fast maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

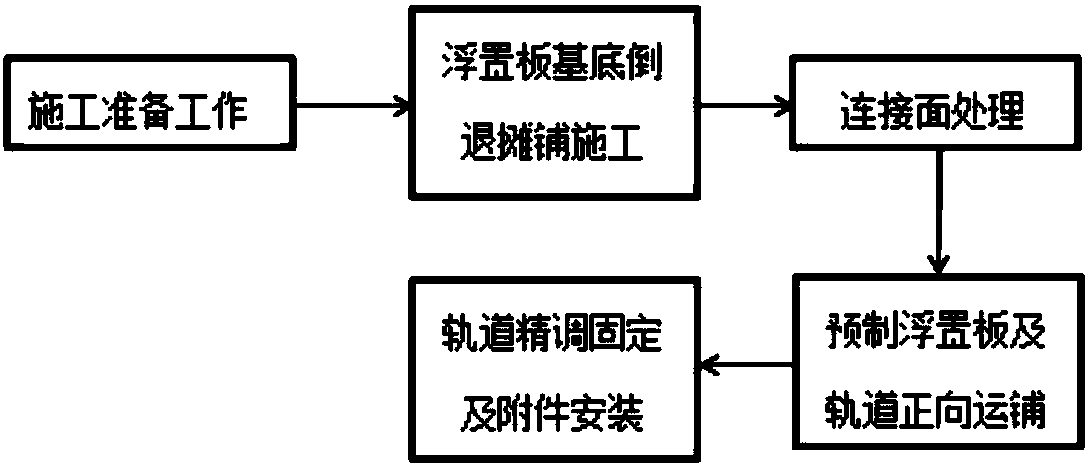

[0032] see figure 1 , The subway slab track bed construction method includes the following processes: construction preparation → floating slab base reverse paving construction → connection surface treatment construction → prefabricated floating slab and track forward laying → track fine adjustment and fixing and accessories installation.

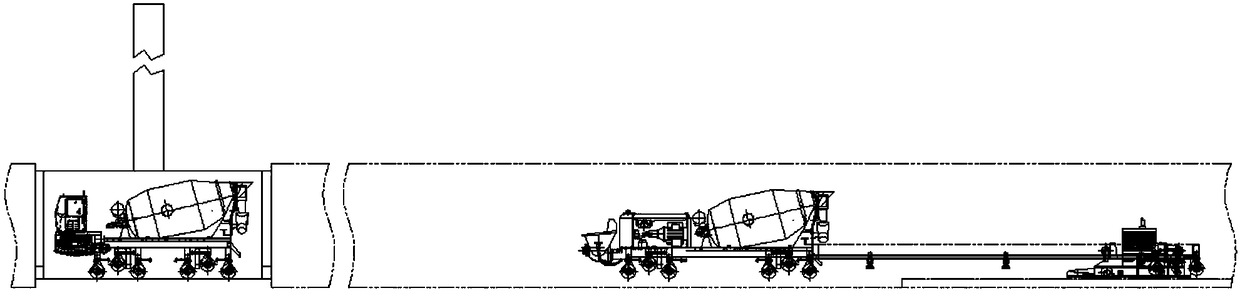

[0033] see figure 2 , a schematic diagram of the base reverse paving construction and the floating slab and track forward paving work of the subway slab track bed construction method, which is characterized in that the base reverse paving construction equipment includes a transport mixer truck 3, a storage truck 5 and a paver 7 ; Floating slabs and track forward laying equipment include laying machines 8 and 11 flat cars.

[0034] Referring to Fig. 3, the reverse paving construction of the floating slab base of the subway slab track bed construction method is characterized in that it comprises the following steps:

[0035] a. If Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com