Automatic switchable box separation device

A box-dividing device and automatic switching technology, applied in the field of machinery, can solve the problems of affecting production efficiency, time-consuming and labor-intensive adjustment process, complicated logistics transportation, etc., and achieve the effect of flexible use, easy adjustment, and improved transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

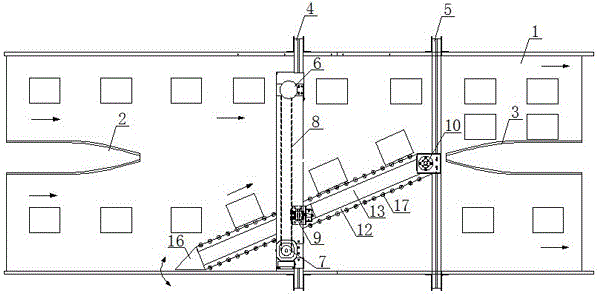

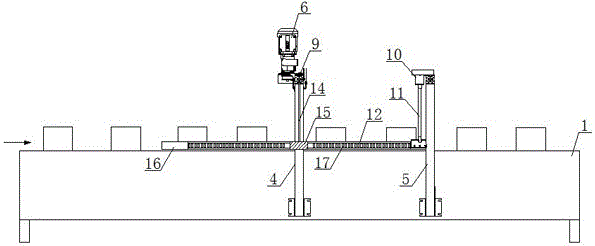

[0014] as attached figure 1 and 2 The shown automatic switchable case dividing device of the present invention includes a conveyor belt 1, a front partition 2, a rear partition 3, a front frame body 4, a rear frame body 5, a driving motor 6, and a tail wheel 7 , transmission chain 8, adjusting plate 9, rotating shaft 10, rotating rod 11, swing arm 12, chute 13, connecting rod 14, slide block 15, guide plate 16 and roller 17, the front and rear ends of described conveyor belt 1 are provided with The front partition 2 and the rear partition 3; the front frame body 4 and the rear frame body 5 are installed in the middle of the conveyor belt 1; the drive motor 6 is fixedly installed on the top of the front frame body 4; the tail wheel 7 passes through The transmission chain 8 is connected with the drive end of the drive motor 6; the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com