A double-clamping coiling device for cold-rolled narrow steel strip

A technology of a coiling device and a clamping device, which is applied in the field of twice-clamping coiling devices, can solve the problems of large opening angle of the clamping tape head, complex clamping device fabrication, poor clamping effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

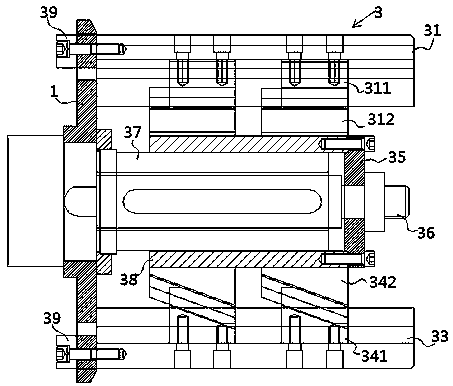

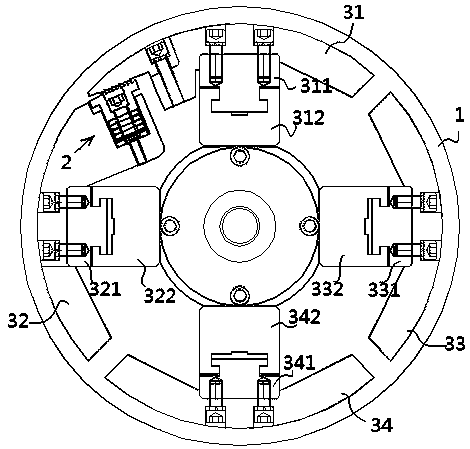

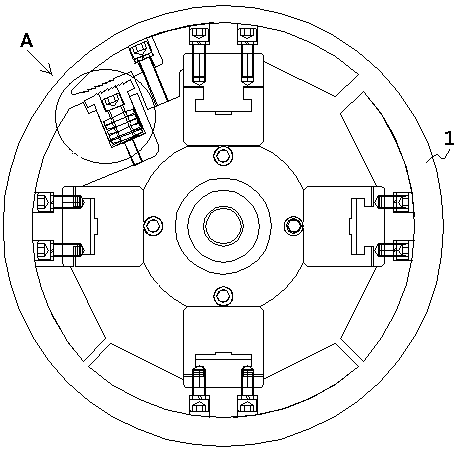

[0037] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a double-clamping coiling device for cold-rolled narrow steel strip in this embodiment includes a back plate 1, a clamping device 2, a reel 3 and a driving mechanism, and the driving mechanism is sequentially arranged from left to right Through the back plate 1 and the reel 3, there is a slider inside the reel 3. Under the action of the above-mentioned driving mechanism, the slider can move the slider along its corresponding chute, and can push the reel to make the positioning block 39 Sliding on the backboard 1 realizes expansion and contraction of the reel 3 , the clamping device 2 is obliquely embedded in the inside of the reel 3 and its outer surface coincides with the side of the reel 3 in the clamped state.

[0038] Reel 3 comprises fixed arc plate 31, jaw arc plate 32, first moving arc plate 33 and second moving arc plate 34, fixed arc plate 31 outer arc surface, jaw arc plate 32 outer arc surfac...

Embodiment 2

[0048] A double-clamping coiling device for cold-rolled narrow steel strip in this embodiment is basically the same in structure as in Embodiment 1, the difference is that the sliding direction of the slider 321 on the jaws is different from that in the horizontal direction. The included angle is 20°, and the included angle between the sliding direction of the first upper slider 331 and the horizontal direction is 15°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com