A fast rotating and swinging impurity removal mechanism

A fast, oscillating axis technology, used in mechanical cleaning, textile and papermaking, dry goods handling, etc., can solve problems such as messy cloth, damage to the quality of textiles, damage to the surface of textiles, etc., to achieve accelerated air circulation, simple structure , the effect of convenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

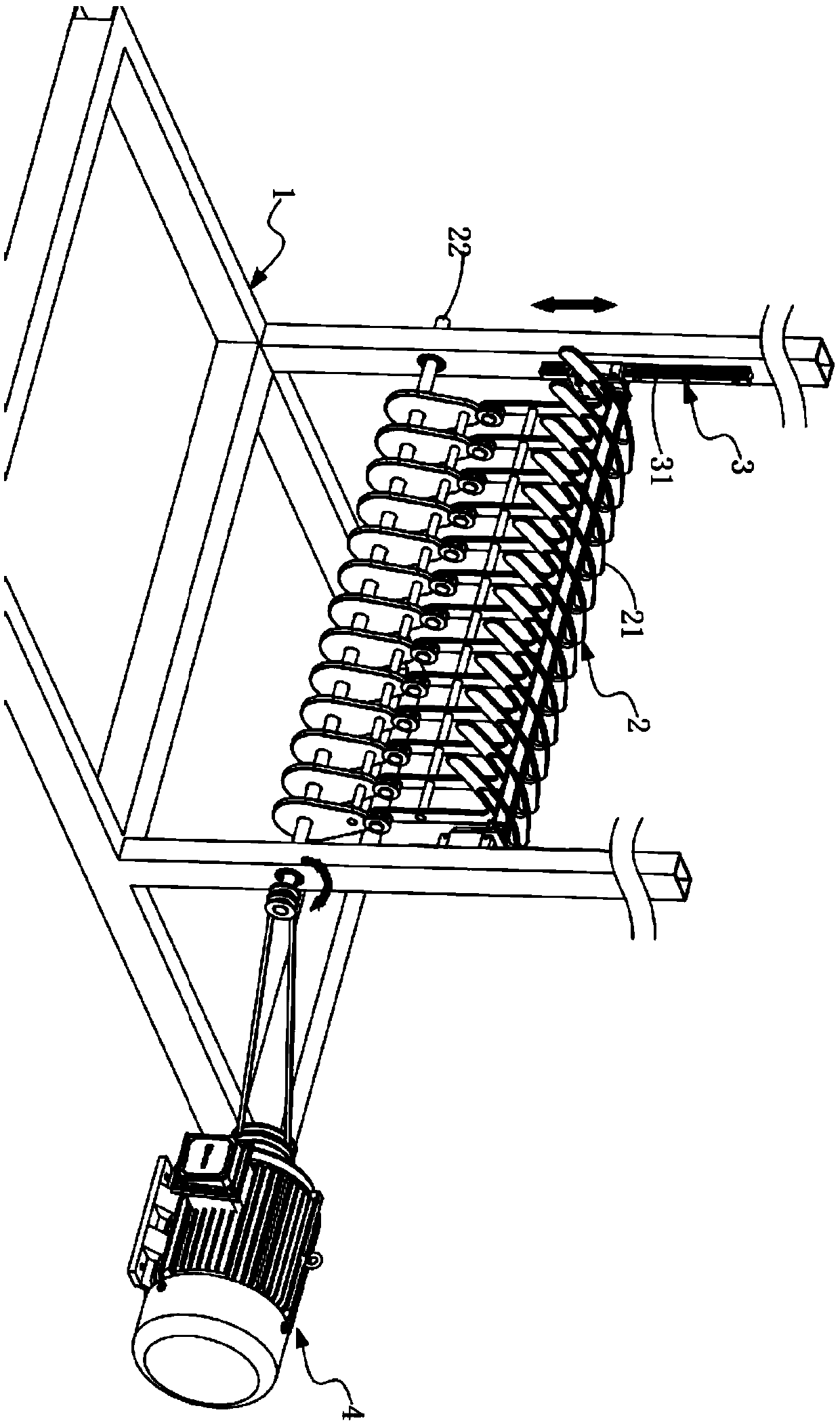

[0028] Such as figure 1 and figure 2 As shown, a fast-rotating swinging impurity removal mechanism includes:

[0029] Rack 1; and

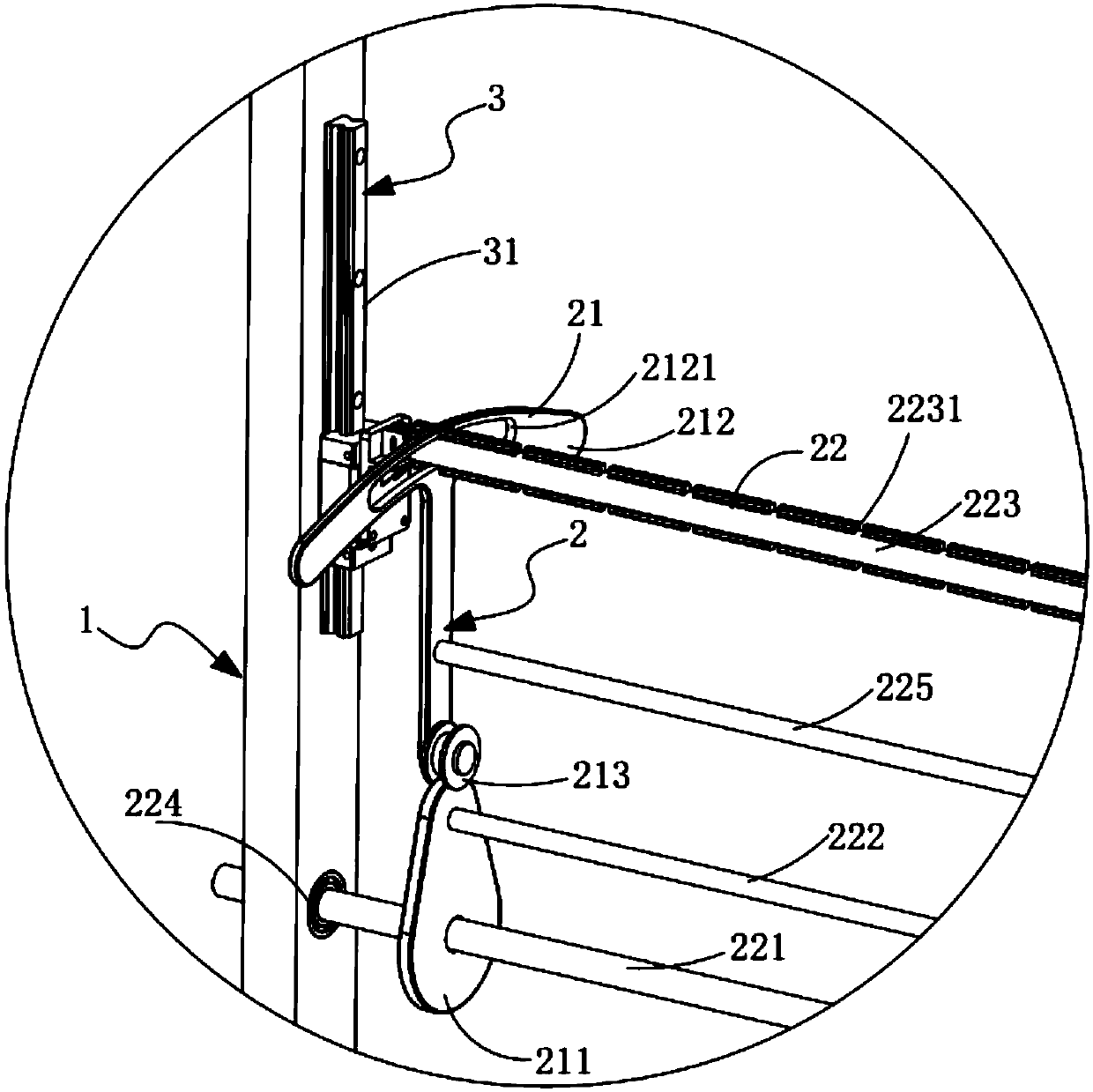

[0030] Rotation and swing assembly 2, the rotation and swing assembly 2 includes at least one rotation and swing unit 21 and a rotation and swing shaft group 22, the rotation and swing unit 21 is arranged on the frame 1 through the rotation and swing shaft group 22, the rotation and swing unit 21 Comprising a cam 211, a swing arm 212 and a roller 213, the cam 211 is arranged on the lower end of the frame 1, and a roller 213 is correspondingly arranged on its edge, the swing arm 212 is located above the cam 211, and its lower end is hinged to the Said roller 213;

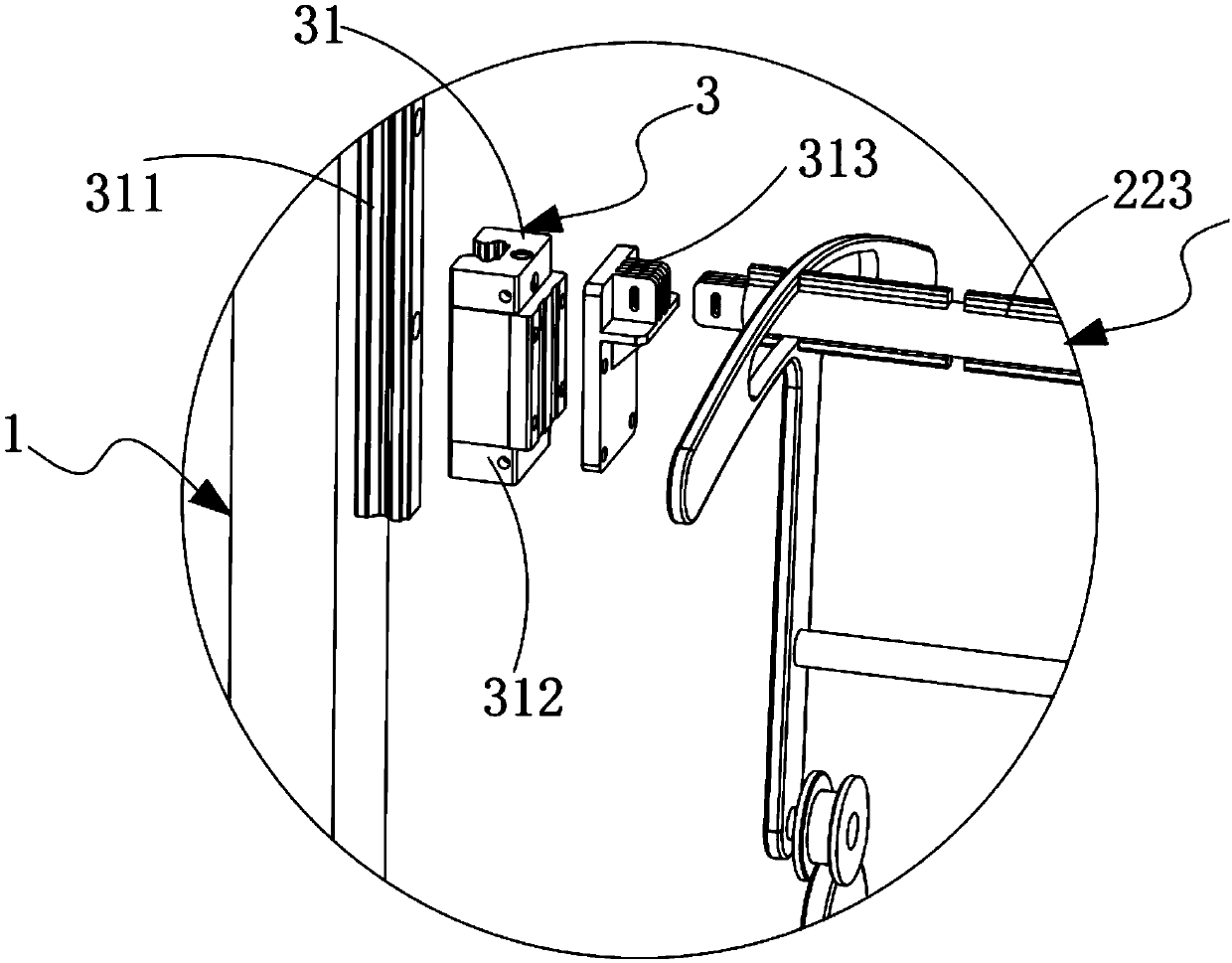

[0031] The guide assembly 3, the guide assembly 3 includes several guide units 31, the several guide units 31 are symmetrically arranged at the front and rear ends of the frame 1, and the guide units 31 are connected to the rotary swing shaft group 22 to swing Unit 21 for guidance. ...

Embodiment approach

[0035] As a preferred embodiment, the rotating and swinging shaft group 22 includes:

[0036] Camshaft 221, the camshaft 221 passes through the large round end of the cam 211, and the cam 211 is fixedly arranged on it, and its two ends are rotatably arranged on the frame 1, and the rotation of the camshaft 221 and the frame 1 The matching place is also provided with a ball bearing 224; and

[0037] The cam synchronous shaft 222, the cam synchronous shaft 222 passes through the small round end of the cam 211, and has an interference fit with it, the cam synchronous shaft 222 is arranged parallel to the cam shaft 221;

[0038] The swing arm shaft 223, the swing arm shaft 223 passes through the swing groove 2121, which is arranged in parallel directly above the cam shaft 221, and the fixed two ends of the swing arm shaft 223 are connected to the guide unit 31;

[0039] The swing arm synchronous shaft 225 is arranged in parallel between the swing arm shaft 223 and the cam shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com