Buffer anchoring tool

A buffer and anchoring technology, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to rotate and move the nut, and unable to tighten the nut, so as to achieve a simple and low-cost solution that does not affect the compression performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

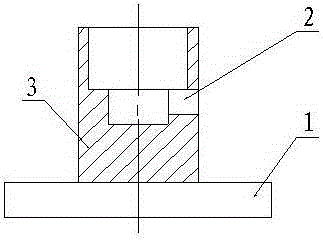

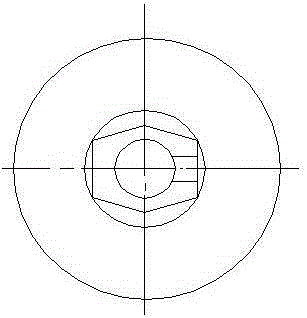

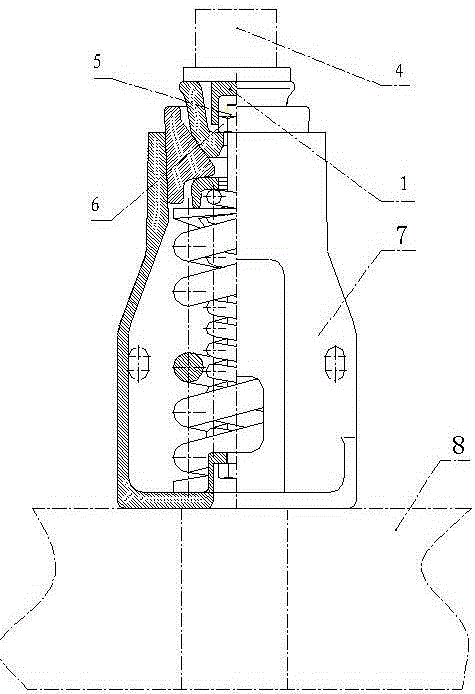

[0010] like figure 1 , 2 As shown, the anchoring tool of the present invention is fixed on a cylindrical seat 1 with an inner hexagonal sleeve 3, which is in a T shape as a whole, and the inner hexagonal sleeve 3 matches the shape of the nut 6 to be assembled. When assembling the buffer 7, the nut 6 is fixed on the nut 6 to be assembled through the inner hexagonal sleeve 3; an observation hole 2 is provided along the radial direction of the inner hexagonal sleeve 3, and the observation hole 2 is connected with the inner hexagonal sleeve 3. The inner holes of the hexagonal sleeve 3 are connected; through the observation hole 2, the number of teeth of the bolt 5 in the buffer 7 to be assembled can be observed to be screwed out of the buffer 7.

[0011] works like image 3 As shown, when in use, the buffer 7 to be assembled is hung on the press table 8, the nut 6 to be assembled is put into the installation position on the top of the buffer 7, and the anchoring tool of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com