Wire harness fixing hook installation error prevention device and wiring harness fixing hook installation method

A technology of wire harness fixing and installation method, applied in the direction of program control and electrical program control in the sequence/logic controller, can solve the problem of wrong and missing installation, the installation module cannot be visually or quantified, and the installation sequence cannot be fixed. problem, to achieve the effect of good practicability and beneficial installation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0042] The present invention will be described in detail below with reference to the accompanying drawings and examples.

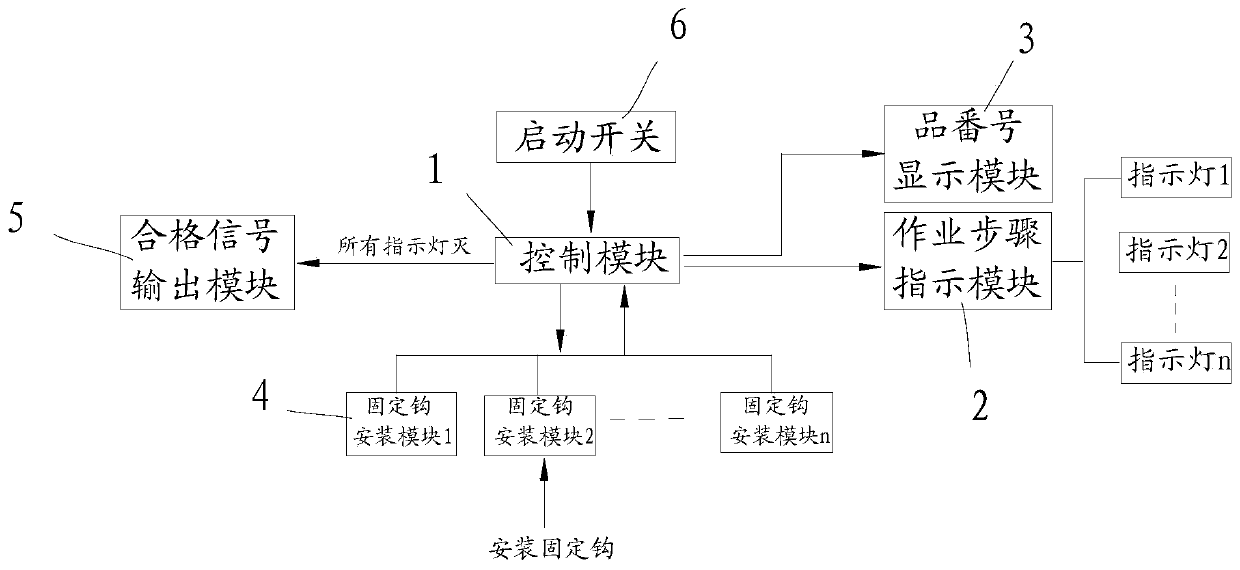

[0043] This embodiment relates to a wiring harness fixing hook installation error prevention device, such as figure 1 As shown in , it includes a control module 1, an operation step indication module 2 connected to the control module 1, a product number display module 3, a fixed hook installation module 4 and a qualified signal output module 5, and the fixed hook installation module is set to multiple , for installation of multiple harness anchors. Wherein, the operation step indication module 2 includes a plurality of first indication units that can be distinguished and can send indication signals under the control of the control module 1, and the fixed hook installation module 4 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com