A method of tuning chirped fiber grating based on plzt

A technology of chirped fiber gratings and fiber gratings, applied in the direction of optical fiber transmission, eliminating distortion/dispersion, etc., can solve problems such as hysteresis effect and oscillation, and achieve fast response, large tuning range, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

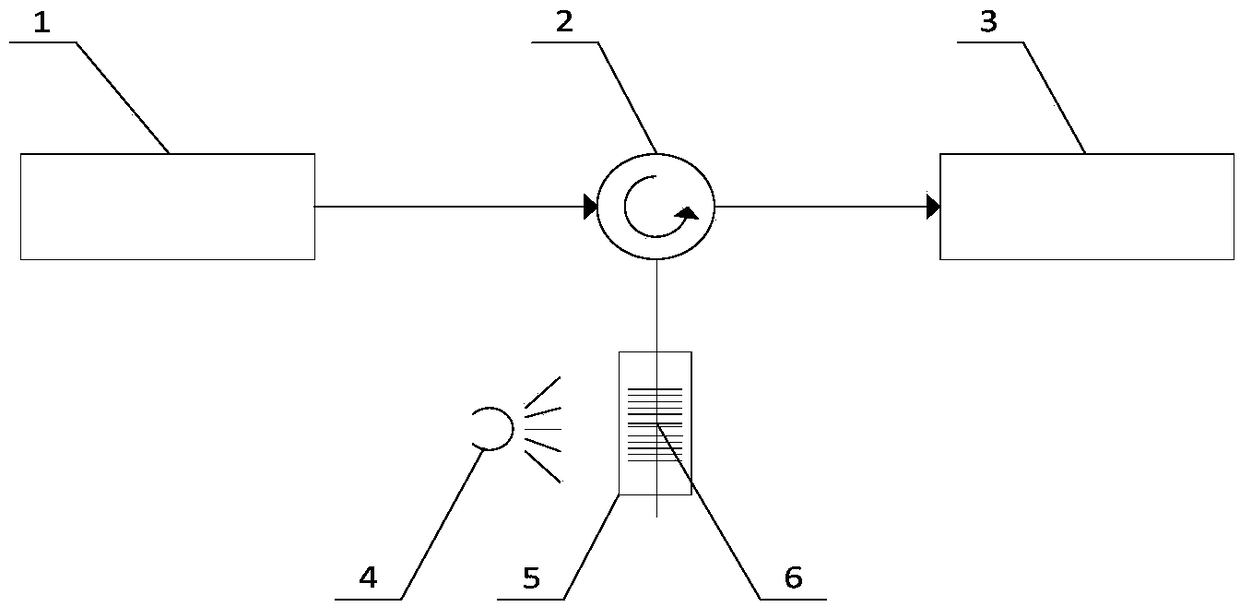

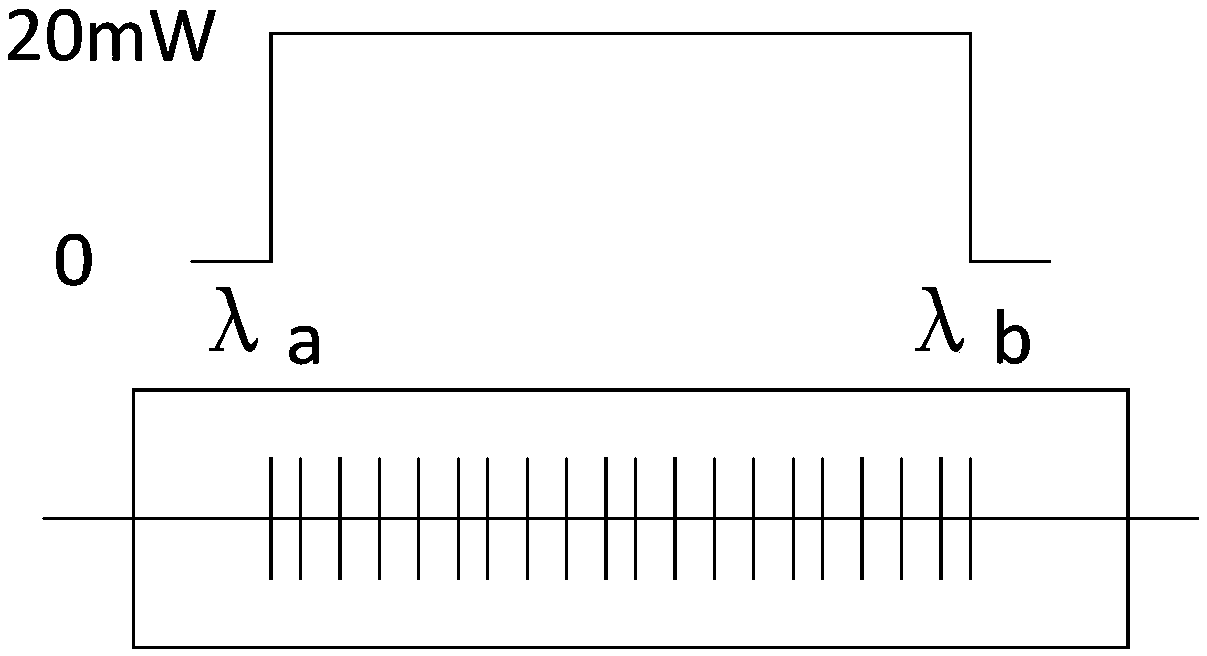

[0038] The central reflection wavelength of the linearly chirped fiber grating 6 tested in the experiment is 1550.9nm, the spectral width is 2nm, and the grating length is 10mm; the central wavelength of the wide-spectrum laser 1 is 1550.9nm, and the half-maximum spectral width is 69nm; the size of the PLZT ceramic sheet 5 is : 15mm×5mm×0.8mm (length, width, thickness); the size of the light source of the ultraviolet lamp 4 is: 30mm×20mm (length, width), and the maximum light intensity is 6000mW / cm 2 . Its test equipment such as figure 1 As shown, the method steps are:

[0039] Step 1: Build an experimental device based on PLZT ceramic chip tuning chirped fiber grating:

[0040] Use epoxy glue to glue the linear chirped fiber grating 6 horizontally on the middle position of the upper surface of the PLZT ceramic sheet 5 along the length direction; place the ultraviolet lamp 4 directly above the upper surface of the PLZT ceramic sheet 5 so that the output port of the light sou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com