Grain flat paving machine

A leveling machine and grain technology, applied in the direction of dryers, partial mixing dryers, dryers for static materials, etc., can solve the problems of low efficiency and high labor intensity, and achieve low labor intensity and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

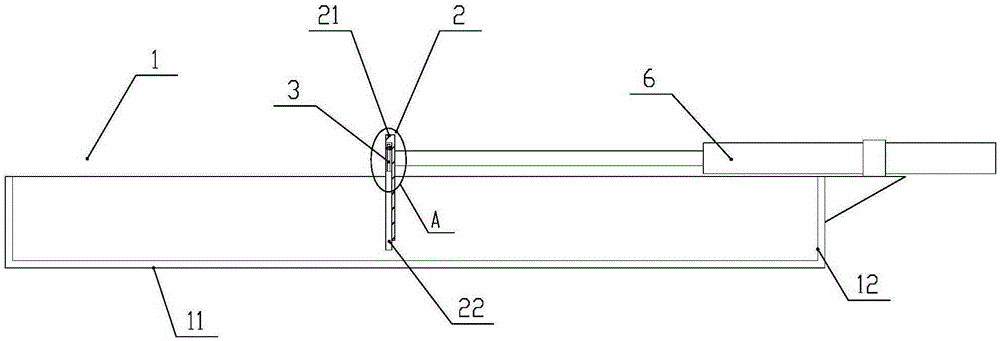

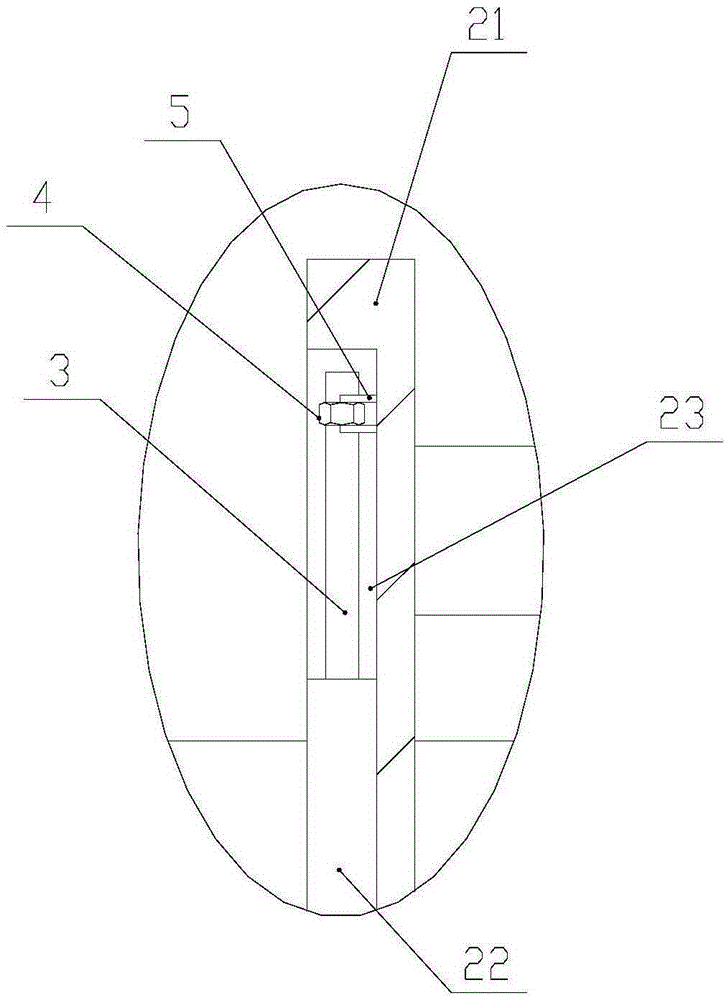

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the grain leveling machine of the present embodiment includes a grain drying tank 1, and the grain drying tank 1 includes a horizontal tank bottom 11 and a tank wall 12 around the tank bottom, It also includes a pusher plate 2 on the bottom of the tank 11 and a transmission mechanism for driving the pusher plate to reciprocate. The pusher plate 2 includes a fixed plate 21 and a sliding plate 22, and the fixed plate 21 is provided with a chute 23. The sliding plate 22 slides up and down in the sliding groove 23 . The pusher plate 2 is driven by a transmission mechanism such as a reciprocating mechanism such as a cylinder 6 to move linearly back and forth on the bottom of the tank, so that the grain in the sun-drying tank 1 is flattened. Since the sliding plate 22 can slide up and down, that is, the distance between the sliding plate 22 and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com