Automatic rope stringing equipment

A rope threading and equipment technology, applied in the field of automatic rope threading equipment, can solve the problems of low labor cost, high operating cost, prominent contradictions, etc., and achieve the effects of easy operation adjustment and maintenance, stable processing quality and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

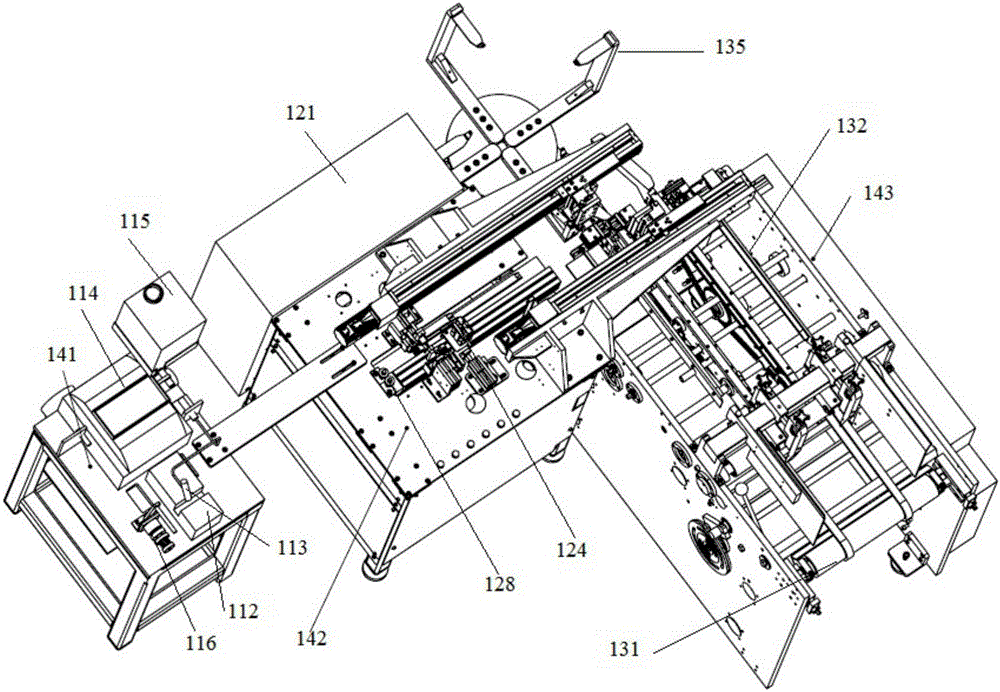

[0030] A kind of automatic rope-threading equipment, its structural diagram is as follows figure 1 As shown, it includes a heading machine unit 141 , a pull rope cutting rope threading unit 142 and a feeding and receiving unit 143 .

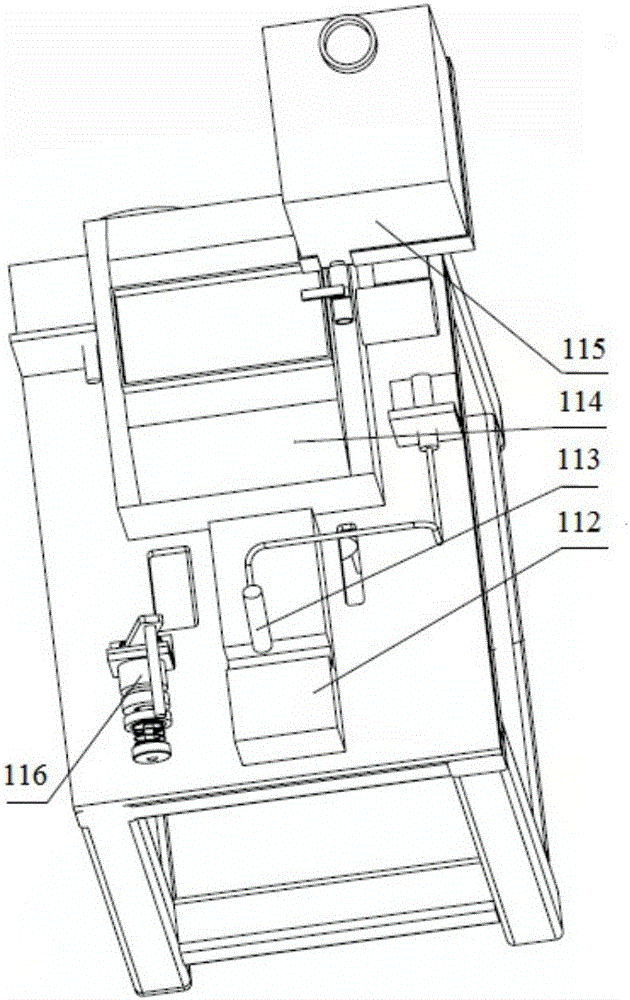

[0031] like figure 2 As shown, the header unit 141 includes a rope feeding mechanism, a rope tension control mechanism 116 and a rope end forming mechanism arranged on the frame. The rope feeding mechanism is a cam transmission box 114 installed on the header unit 141 frame, and the cam transmission box 114 is positioned at one side of the rope tension control mechanism; The glue head is connected with the solvent charging box through the infusion tube;

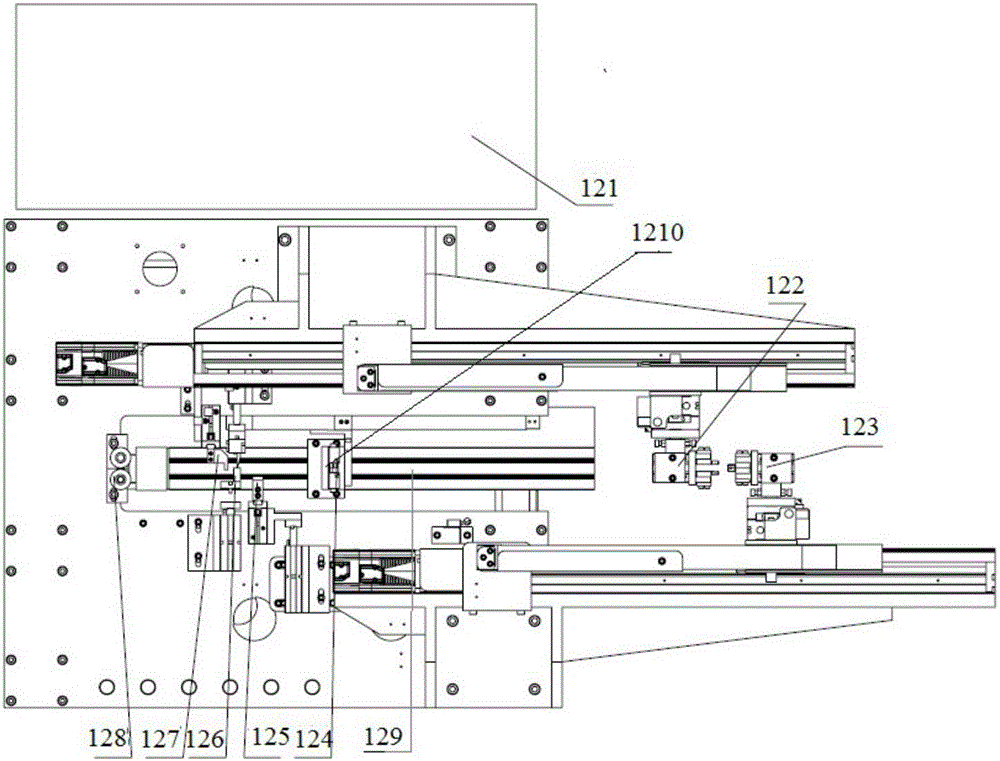

[0032] like image 3 As shown, the rope cutting and threading unit 142 includes a rope cutting device and a rope threading device arranged in sequence, and the rope cutting device is opposite to the rope end forming mechanism. The rope-stay cutting device comprises a rope-stay mechanism and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com