Grain crop seed testing platform in assembly line type operation, and application and preparation method thereof

An assembly-line, grain-based technology, applied in the direction of testing plants/trees, measuring devices, instruments, etc., can solve the problems that the steps are difficult to complete smoothly and continuously, affect the accuracy of the test species, and the work is cumbersome, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is illustrated below in conjunction with the accompanying drawings, but not as a limitation to the scope of the present invention.

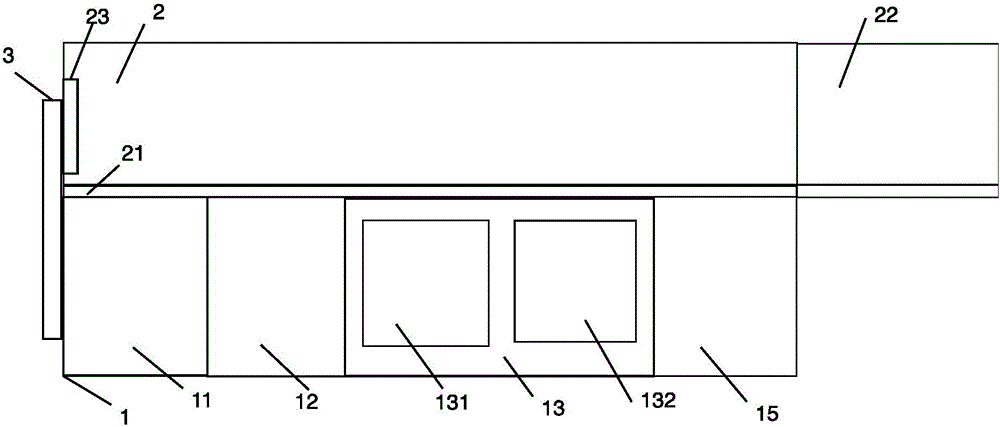

[0051] Such as figure 1, an assembly line operation platform for seed crop testing, characterized in that it includes a workbench body, the workbench body includes a seed test area 1; the seed test area 1 is along one end of the workbench body to The other end is a strip-shaped area, in which a threshing area 11, a cleaning area 12, and a weighing and counting area 13 are arranged adjacently in sequence;

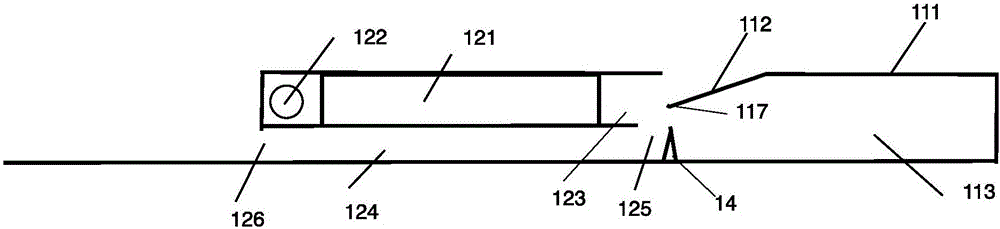

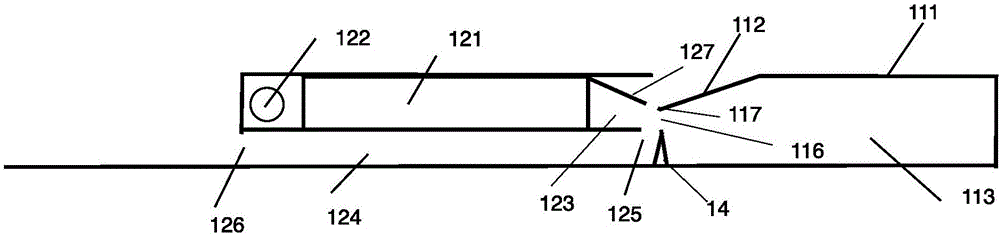

[0052] The threshing area 11 has an upper surface, an inner bottom surface, and an impurity collection bin 113 composed of the upper surface and the inner bottom surface;

[0053] The cleaning area 12 is a box-like structure with a top wall and an inner bottom surface, one side adjacent to the threshing area 11 and the opposite side open, and the channel between the openings is divided into bottom seed Channel 124...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com