An automatic rail clamping and stepping device for inclined shafts of open rock tunnel boring machines

A tunnel boring machine and open-type technology, which is applied to the field of automatic rail clamping and stepping devices for inclined shafts of open-type rock tunnel boring machines, can solve the problems of personnel injury and construction failure, reduce stepping speed, increase labor force, etc., and achieve a simple structure. , compact space, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

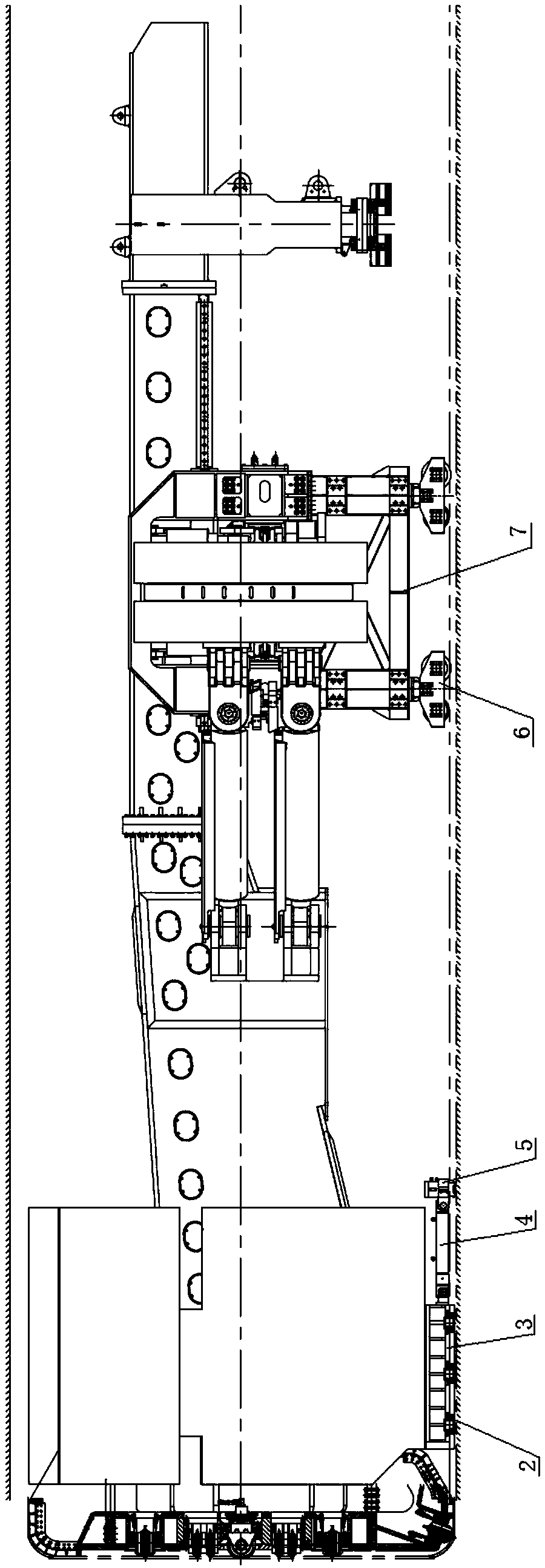

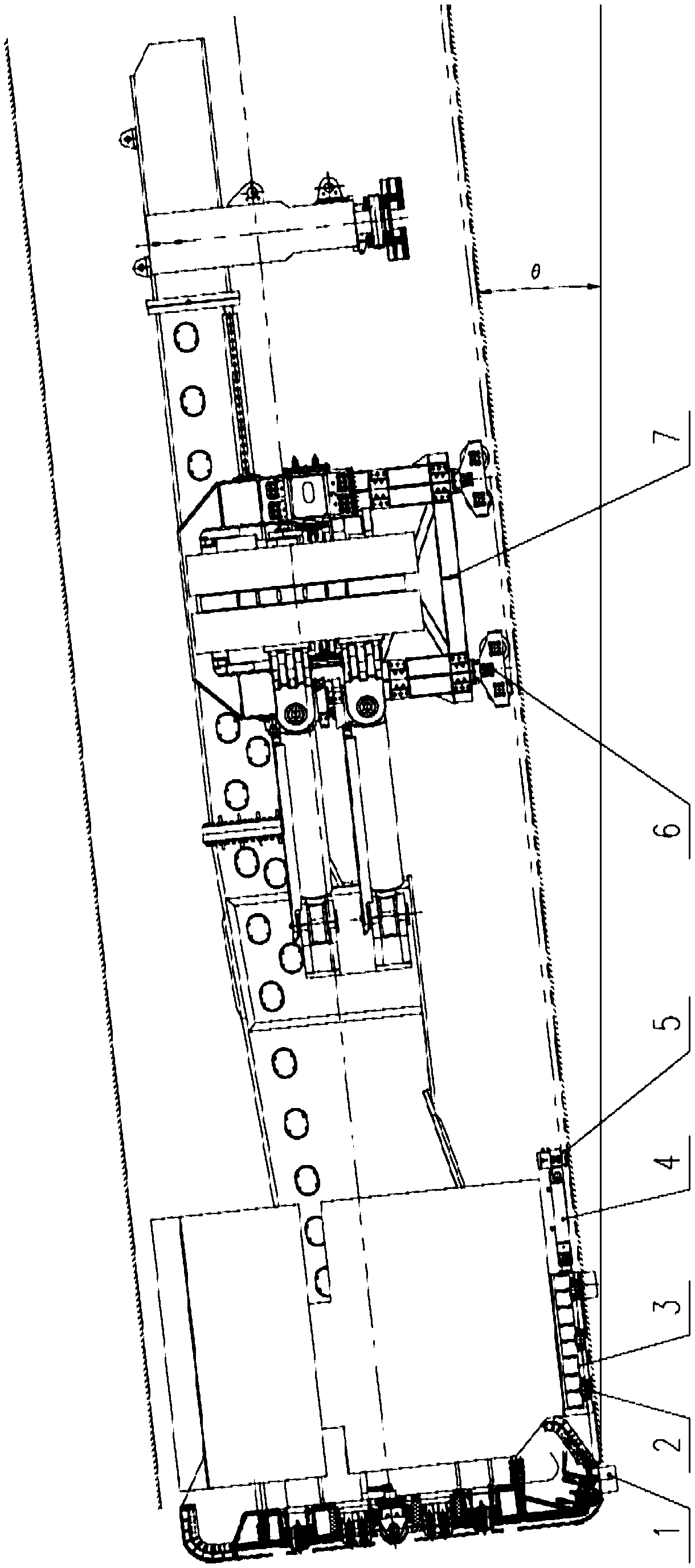

[0041] like figure 1 and figure 2 As shown, the present invention provides a first embodiment of an automatic rail clamping and stepping device for an inclined shaft of an open rock tunnel boring machine, which mainly includes: a guide block 1, a lateral guide wheel 2, a slide rail plate 3, and a stepping oil cylinder 4. Rail clamp 5, traveling mechanism 6, saddle frame support 7, hydraulic system pipeline 8, electrical control system, etc.

[0042] Specific as Figure 3 to Figure 7 As shown, the slide rail plate 3 is arranged under the bottom shield 9 of the TBM (Tunnel Boring Machine, full-face tunnel boring machine) main engine, the cutter head 10 is arranged in front of the bottom shield 9, and the running gear 6 and The saddle support 7 is arranged behind the bottom shield 9 in sequence.

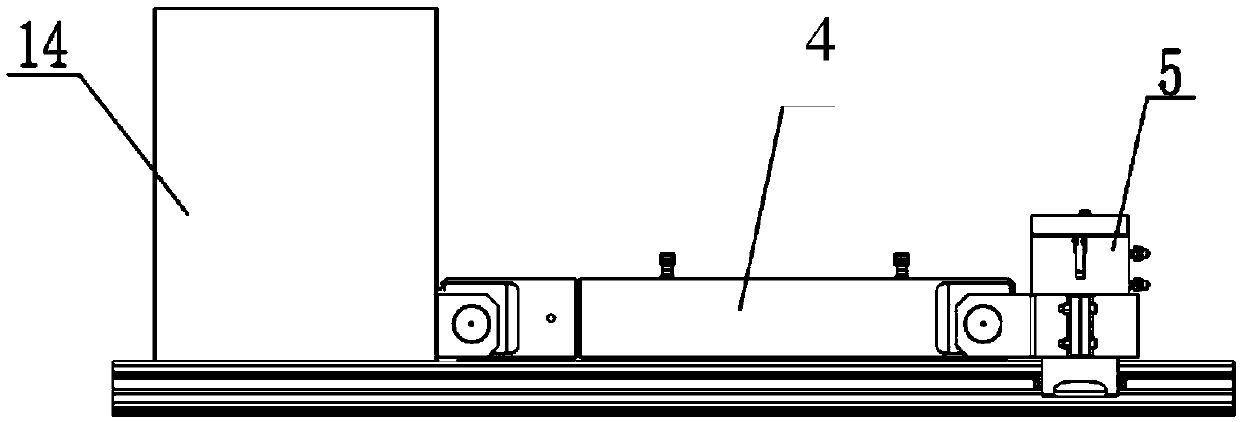

[0043] The rear of the slide rail plate 3 is connected with the rail clamp 5 through the stepping oil cylinder 4 . Specific as Figure 4 As shown, the rail clamp 5 mainly includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com