Potato planting machine

A potato planter and rack technology, applied in potato planters, planting methods, agricultural machinery and implements, etc., can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

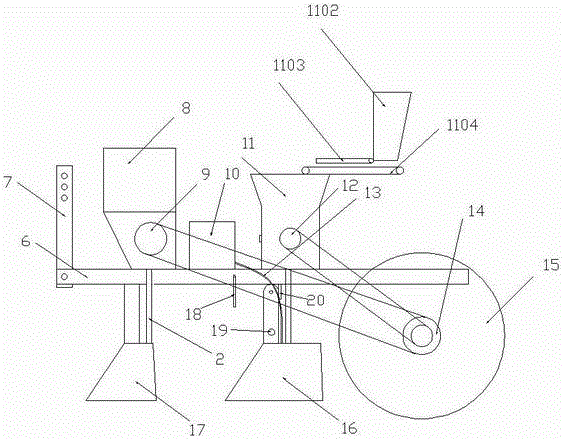

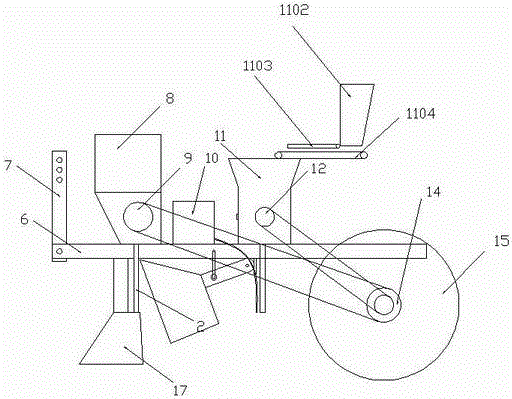

[0012] The specific implementation of the present invention is explained below.

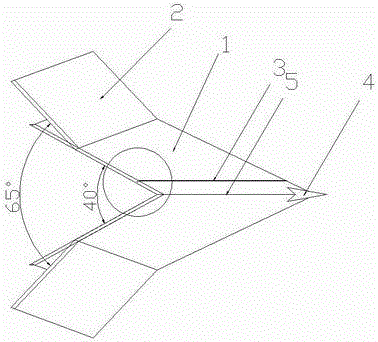

[0013] Such as figure 1 with 2 Shown, a kind of potato planting machine comprises frame 6; Be arranged on the fertilizer box 8 on the frame, be arranged on the fertilizer device in the fertilizer box, the fertilizer device sprocket wheel 9; Seed material box 11, be arranged on seed material Seed metering device in the box, seed metering device sprocket wheel; Water tank 10 and water pipe 13; Ground wheel 15; Sowing ditch opener 16; Installed on the frame 6, the upper end of the column is a semicircular head, the uppermost point of the semicircular head is against the frame 6, the center of the semicircular head has a pin hole, the pin passes through the pin hole of the column, and the two ends of the pin are fixed on On the fixed lug of the pin shaft that frame 6 extends downwards, the column can rotate around the pin shaft, and the baffle plate 20 that vertically downwards is arranged on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com