Hydraulic pile driver for highway guardrails

A technology for road guardrails and piling machines, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of low drop hammer precision, lower construction quality, and low automation, and achieve high piling accuracy, quality assurance, and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further explained below in conjunction with the accompanying drawings.

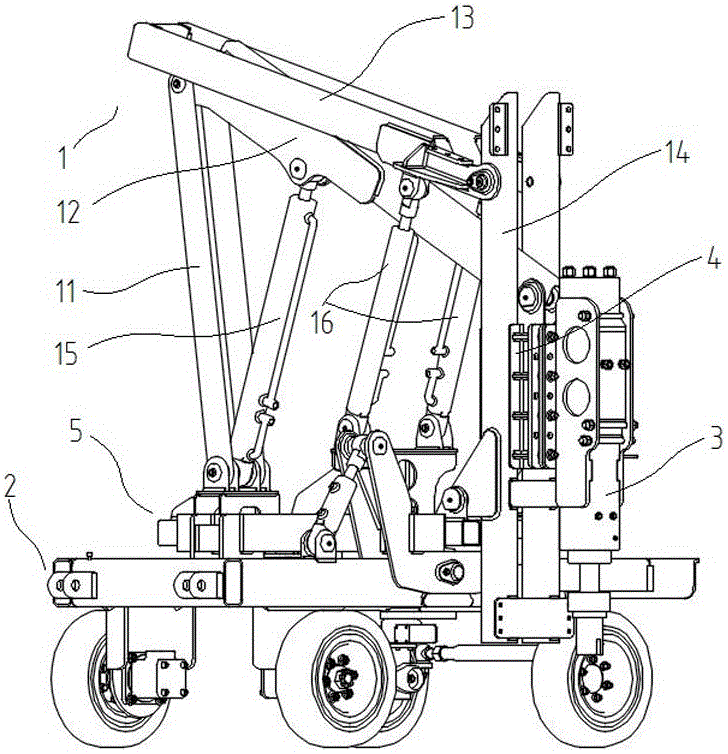

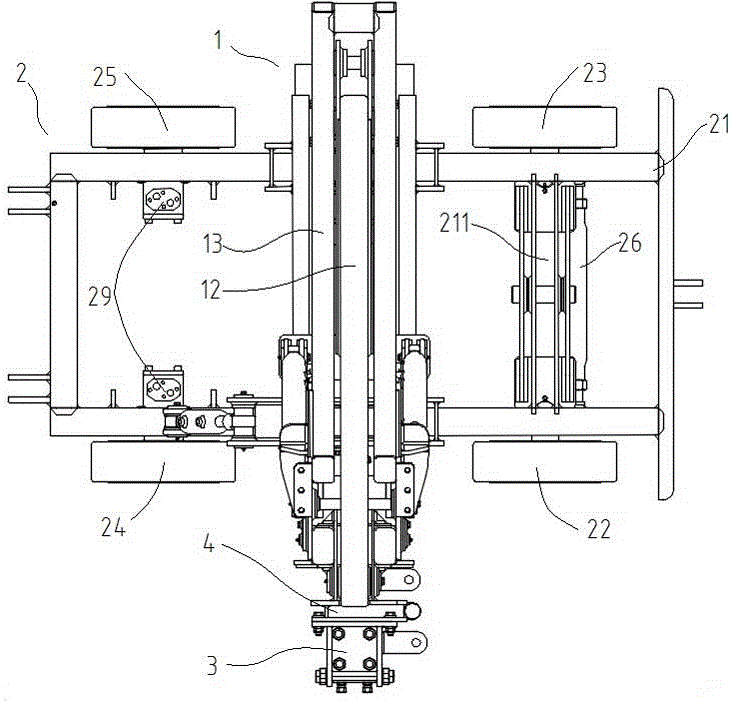

[0039] The road guardrail hydraulic pile driver of the present invention comprises a pile frame 1, a four-wheel chassis 2 for supporting the pile frame 1, a hydraulic hammer 3, a hinge type carriage 4 that drives the hydraulic hammer 3 to slide on the pile frame 1 and is arranged on The four-wheel chassis 2 is used to drive the telescopic mechanism 5 for adjusting the vertical and horizontal swing of the pile frame 1 in the horizontal plane; Figure 10 , the hydraulic hammer 3 includes a drill rod 31 and a drill cap 32; the telescopic mechanism 5 is provided with a guide rail cylinder ear plate 531, a swing arm cylinder ear plate 532 and a lower guide rail hinge plate 535;

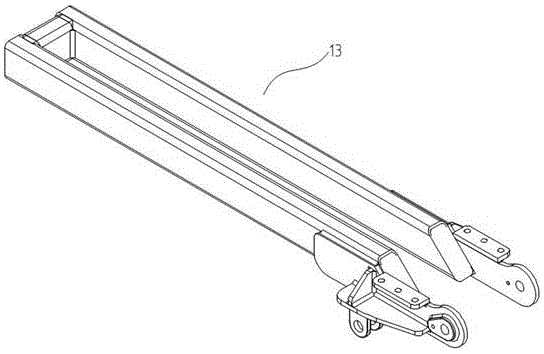

[0040] The pile frame 1 includes a connecting plate 11, a swing arm 12, an upper guide rail 13, a lower guide rail 14, a swing arm cylinder 15 and a guide rail cylinder 16;

[0041] One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com