A horizontal telescopic ultra-wide bridge inspection vehicle

A technology of bridge inspection vehicle and horizontal expansion, which is applied in the direction of bridges, bridge construction, bridge parts, etc. It can solve the problems that the inspection vehicle cannot meet the actual requirements, the inspection personnel have no safety guarantee, and the safety measures are not perfect, so as to reduce the casualties of inspection personnel , Improve operational safety and reduce casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

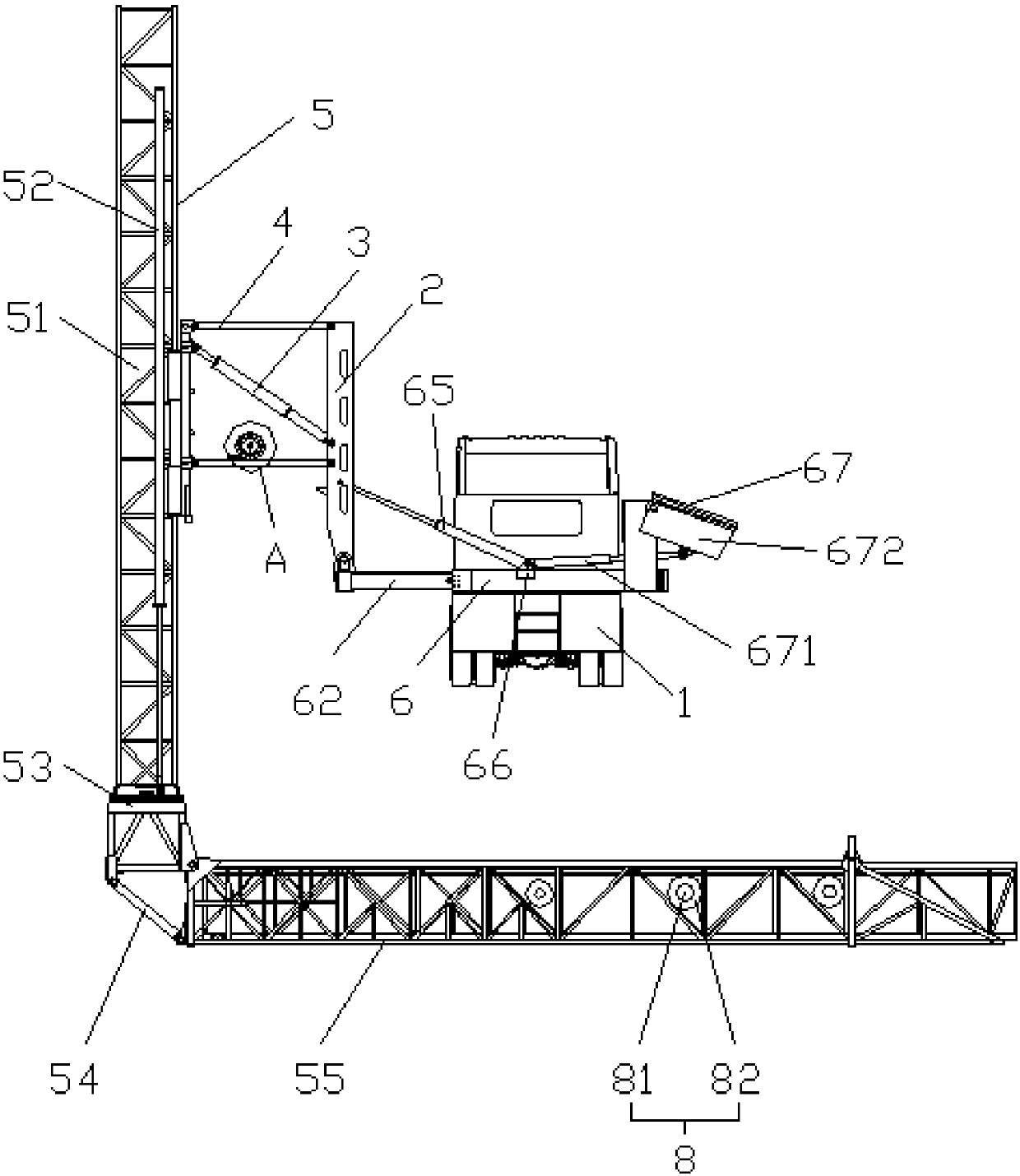

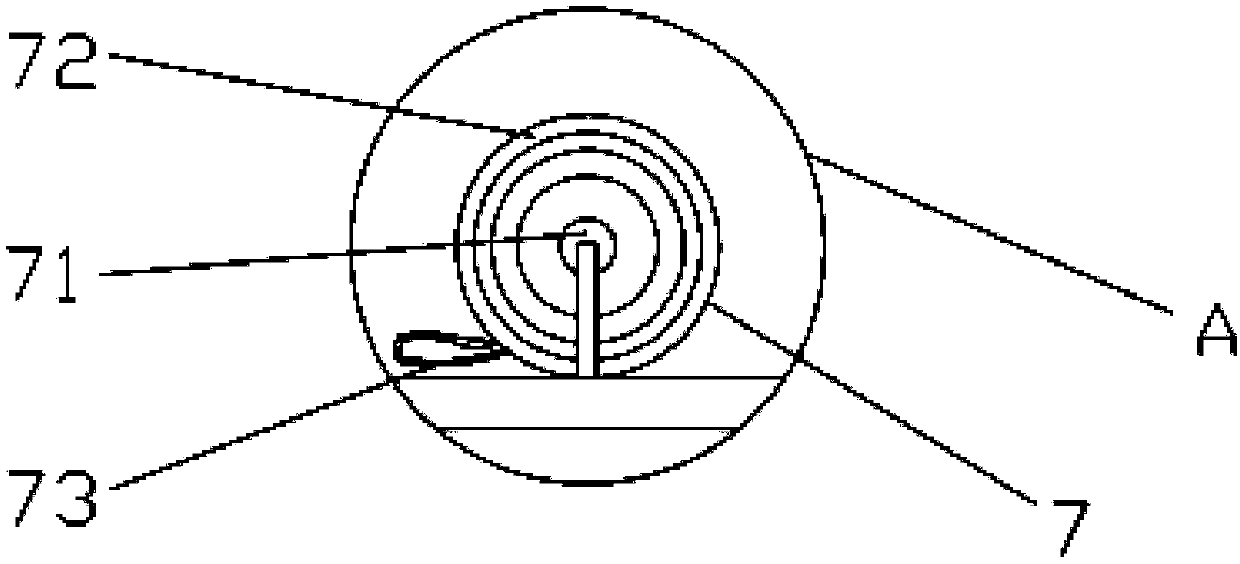

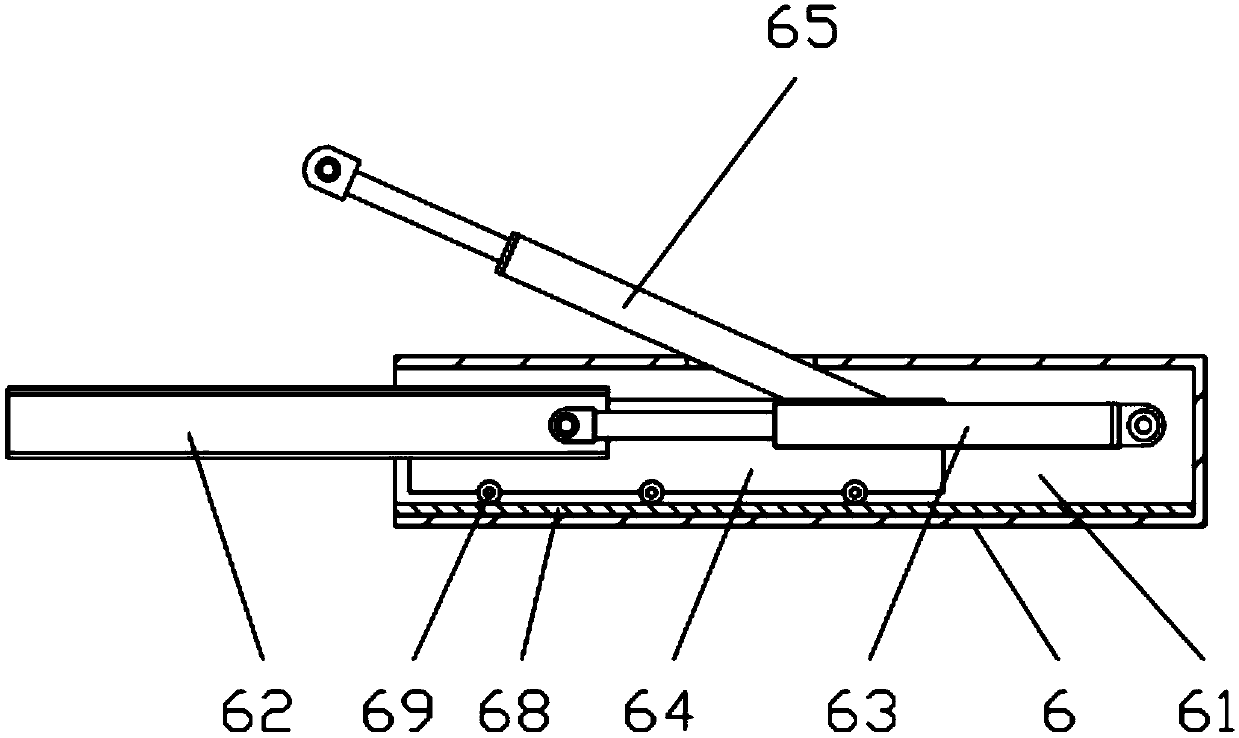

[0019] Such as Figure 1-4 As shown, a horizontally telescopic ultra-span bridge inspection vehicle includes a car body 1, an overturning platform 2, a connecting rod cylinder 3, a connecting rod 4 and a whole truss 5, and the overturning platform 2 passes through the connecting rod cylinder 3 and The connecting rod 4 is connected with the whole truss 5 to realize the turning over of the whole truss 5 . The car body 1 is provided with a large turntable 6, and the inside of the large turntable 6 is provided with a slideway 61, and the slideway 61 is provided with a telescopic arm 62 and a telescopic oil cylinder 63, and one end of the telescopic arm 62 is connected to the telescopic oil cylinder. 63 connection, the other end of the telescopic arm 62 is hinged with the overturning platen 2, and the telescopic oil cylinder 63 pushes the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com