High-speed railway turnout large-size component replacing and laying device and method

A technology for high-speed railways and large parts, which is applied in the field of high-speed railway turnout and large parts replacement equipment. It can solve the problems of failure to meet requirements, time-consuming, permanent deformation and laying accuracy of large parts and accessories of turnouts, and reduce labor intensity. Effects of shortening construction work time and improving quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing.

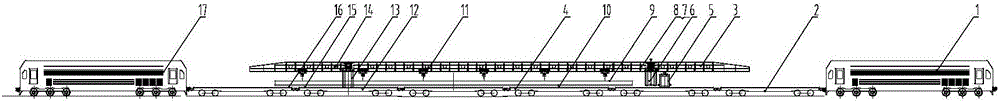

[0046] Such as figure 1 As shown, the present embodiment provides a kind of high-speed railway turnout large parts replacement equipment, which includes a traction rail car 1, a first flat car group 2, a second flat car group 4, a third flat car group 12, a power generation rail car 17. Machine arm 3, machine arm bogie 5, movable support 6, fixed support 13, lifting trolley 11, electrical control system 16. The first flat car group is used to support the arm transport bogie and the fixed pillar; the second flat car group is used for the transportation and recovery of large parts of the turnout; the third flat car group is used to support the fixed pillar, during the transportation and construction process Among them, the fixed pillar 13 is always supported on the third flat car group 12, the machine arm 3 is the main load-bearing structure, the lifting trolley 11 is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com