A method for producing starch-zinc complex nutritional enhancer by using pulsed electric field

A nutrient enhancer and pulse electric field technology, applied in the field of modified starch, can solve the problems of long reaction time between starch and metal, high cost of enzymatic degradation, and easy falling off of zinc ions, so as to improve the efficiency of coordination reaction and reduce the activation energy of reaction , The effect of shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

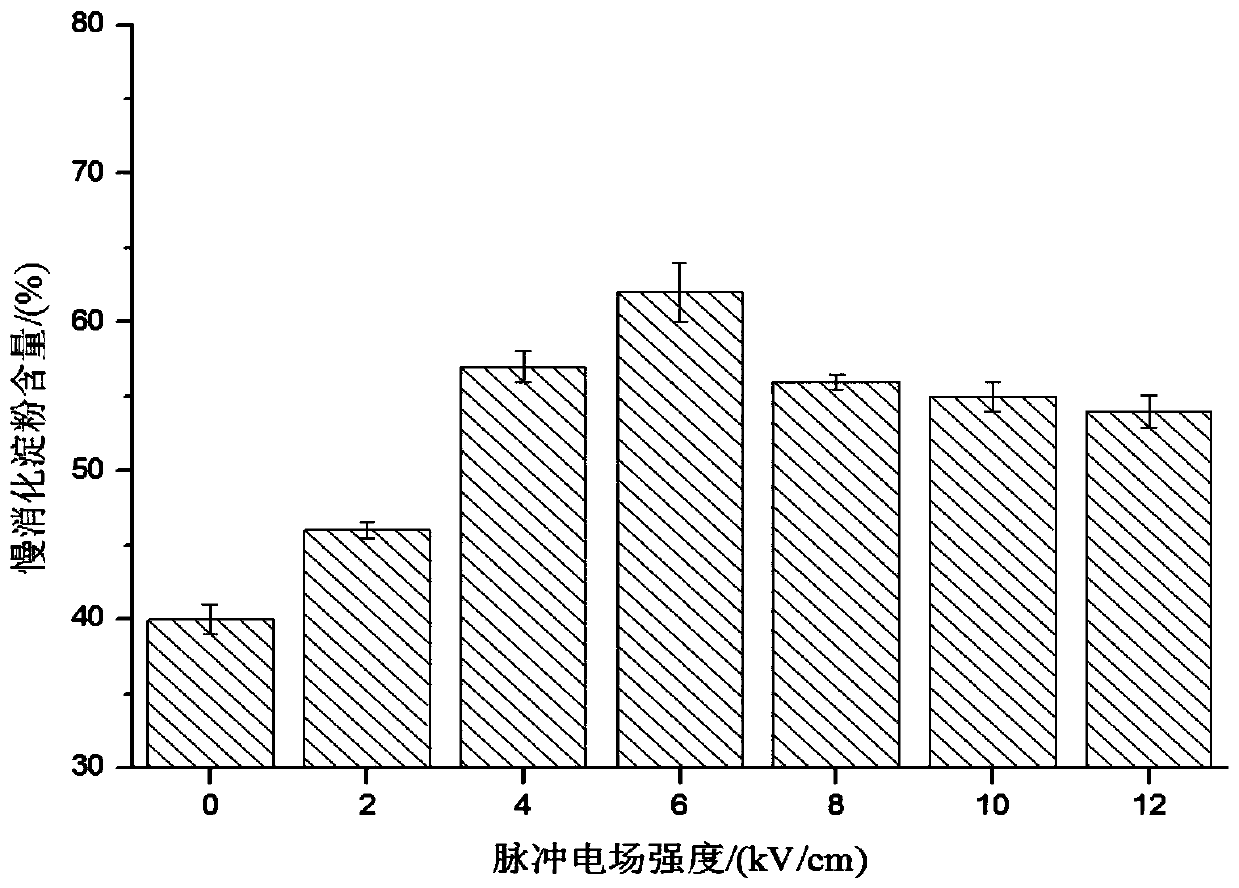

[0040] Rice starch and 0.02mol / L zinc acetate solution were configured as an emulsion with a concentration of 30% (w / v), mixed for 3 minutes, adjusted to pH 6.5 with sodium hydroxide solution, and chlorinated with 0.2mol / L Sodium adjusted the conductivity of the above solution to 0.5mS / cm, and then treated it with a pulsed electric field for 0.5 hours, wherein the pulsed electric field intensity was 4.0kV / cm, the pulse width was 40μs, and the flow rate was 100L / h, and it was washed with deionized water for several times until There is no free zinc, and finally washed with absolute ethanol, suction filtered, dried in an oven at 40°C, and then ground and dried at 80 mesh to obtain a starch-zinc complex nutrition enhancer with a zinc content of 140mg / g. The conversion rate was 40%, and the SDS was 57%, the data is shown in figure 1 , figure 1 Under the above conditions, the content of slowly digestible starch (SDS) in starch complexes under different pulse electric field intensi...

Embodiment 2

[0042] Potato starch and 2.0 mol / L zinc acetate solution were configured as an emulsion with a concentration of 10% (w / v), mixed for 3 minutes, adjusted to pH 7.0 with sodium hydroxide solution, and chlorinated with 0.3 mol / L Sodium adjusted the conductivity of the above solution to 1.0mS / cm, and then treated it with a pulsed electric field for 1.5 hours, wherein the pulsed electric field intensity was 6.0kV / cm, the pulse width was 40μs, and the flow rate was 200L / h, and it was washed with deionized water several times until There is no free zinc, finally washed with absolute ethanol, suction filtered, dried in an oven at 40°C, and then ground and dried at 60 mesh to obtain a starch-zinc complex nutrition enhancer with a zinc content of 220mg / g. The conversion rate is 78%, and the SDS is 60%, the data can be found in image 3 , image 3 Under the above conditions, the zinc content and conversion rate in the starch complex under different pulse electric field intensities.

Embodiment 3

[0044] Cornstarch and 2.0mol / L zinc acetate solution were configured as an emulsion with a concentration of 8% (w / v), mixed for 3 minutes, adjusted to pH 8.0 with sodium hydroxide solution, and chlorinated with 0.3mol / L Sodium adjusted the conductivity of the above solution to 2.0mS / cm, and then treated it with a pulsed electric field for 2.5 hours, wherein the pulsed electric field intensity was 6.0kV / cm, the pulse width was 40μs, and the flow rate was 100L / h, and it was washed with deionized water for several times until No free zinc exists, finally washed with absolute ethanol, suction filtered, dried in an oven at 40°C, then ground and dried at 80 mesh to obtain a starch-zinc complex nutritional enhancer with a zinc content of 230mg / g. The conversion rate is 80%, and the SDS is 62%, the data can be found in Figure 4 ,in Figure 4 Under the above conditions, the zinc content and conversion rate in the starch complex after different pulse electric field treatment times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com