A fully automatic snail shell breaking machine

A fully automatic, shell-breaking machine technology, applied in the processing of crustaceans, slaughtering, food science, etc., can solve the problems of hand muscle strain, high shell hardness, high labor intensity, etc., to reduce labor intensity and improve safety. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

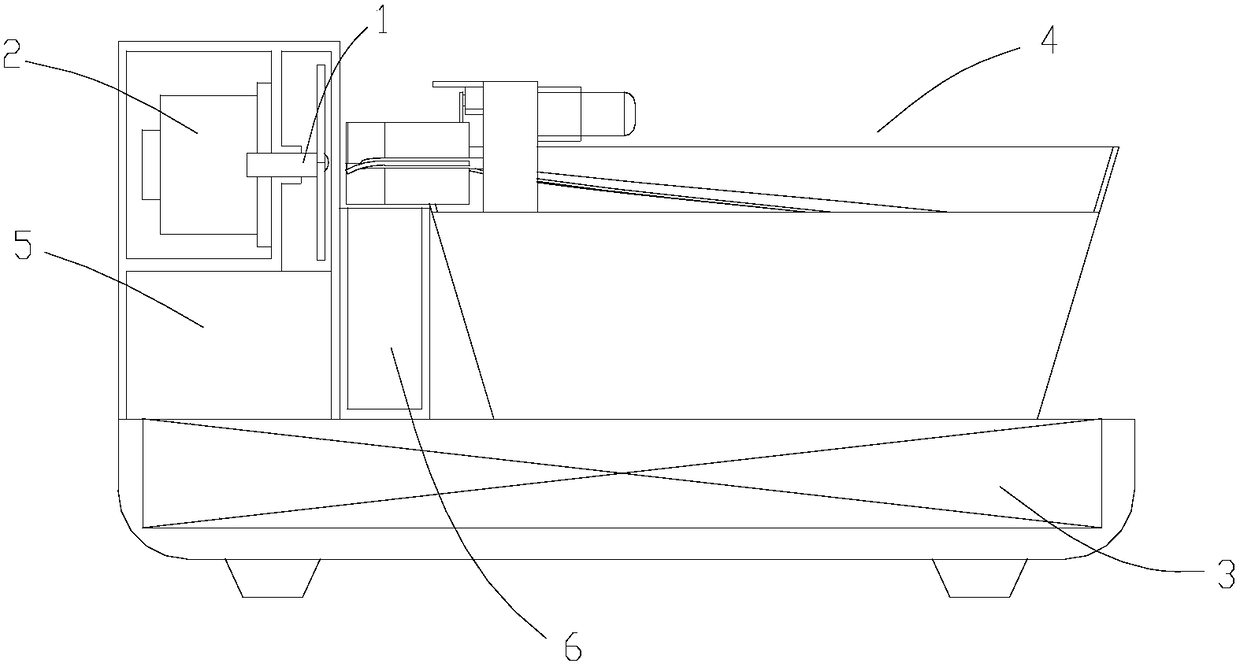

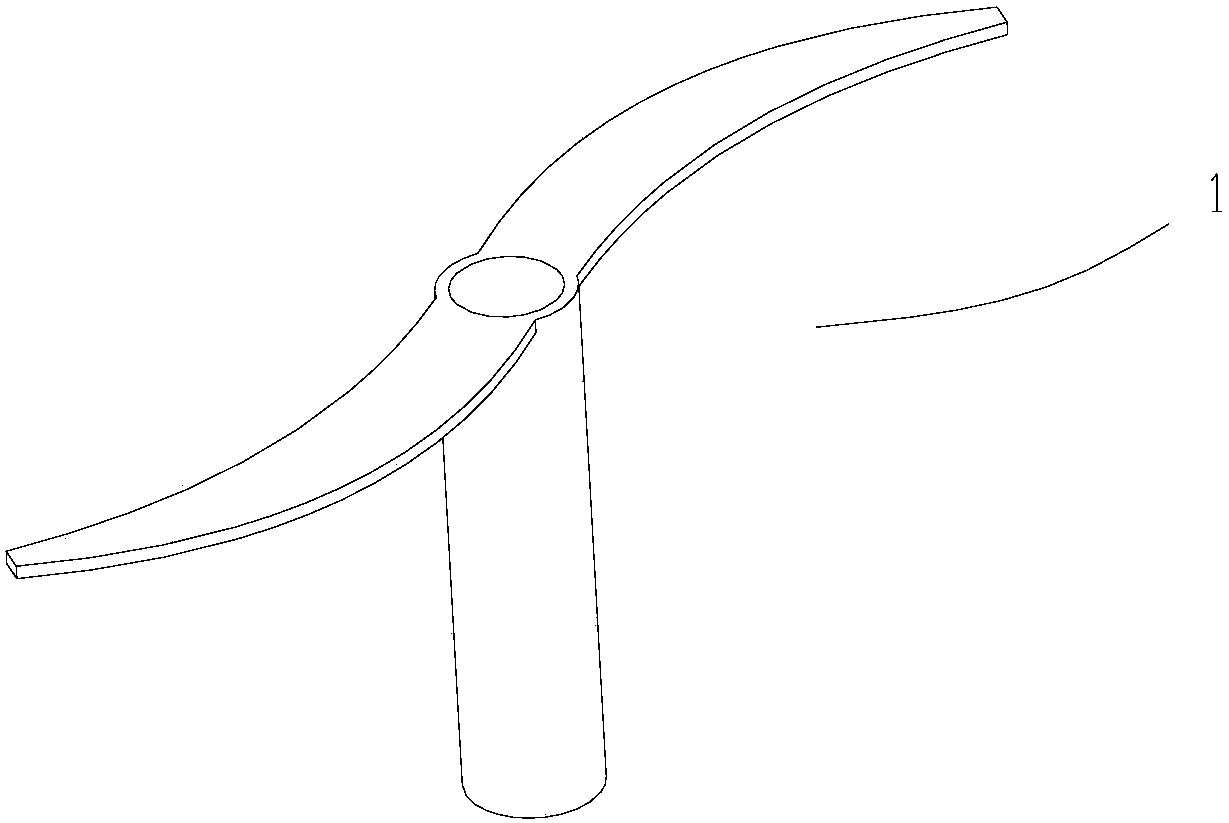

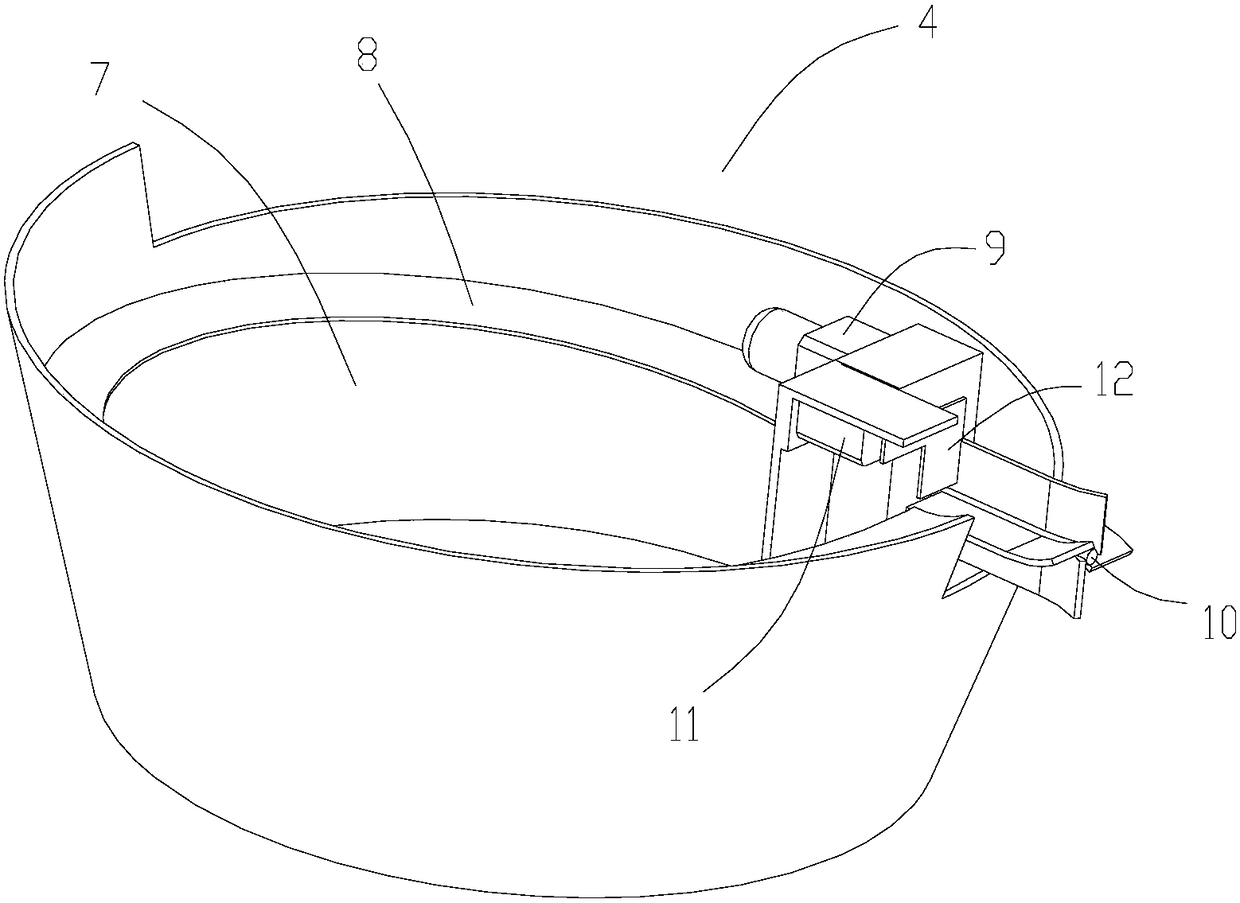

[0034] see Figure 1 to Figure 2 , the present invention discloses a full-automatic snail shell breaking machine, which comprises a case, a blade 1, a main motor 2, an electrical assembly 3, a feeding device 4, a crushing hopper 5 and a collecting hopper 6; the case is L-shaped and includes a The base and the host cavity standing on the upper part of the base, there is an L-shaped partition inside the host cavity, the partition divides the host cavity into a knife cavity for installing the blade 1 and a motor cavity for installing the main motor 2, the knife cavity The side of the blade is provided with a cutting hole for placing the shell; the bottom of the knife cavity is completely penetrated, and the broken shell bucket 5 is detachably installed directly below the knife cavity; 1 is installed in rotation on the partition, the blade is facing the side of the cutting hole; the main motor 2 is installed in the motor cavity and connected with the blade 1; the feeding device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com