Adobe stacking machine and adobe stacking method

A blank-stacking machine and brick-brick technology, applied in the field of automation machinery in the building materials industry, can solve the problems of increasing the overall height of the equipment, increasing the production cost, and brick-brick deformation, shortening the installation and debugging cycle, saving production costs, and avoiding blank collapse events. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in conjunction with specific examples now. The following descriptions are only preferred implementations, and of course the scope of rights of the present invention cannot be limited with this. Therefore, the equivalent changes made according to the technical solutions of the present invention still belong to the scope covered by the present invention .

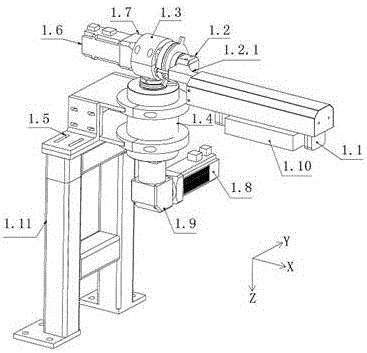

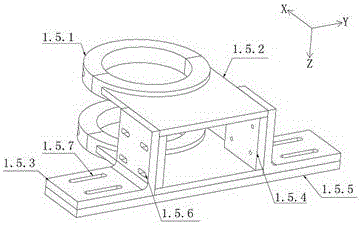

[0034] like figure 1 and Figure 4 As shown, the stacking machine includes a small manipulator 1, a conveying line 2, a large manipulator with a movable gantry 3 as a frame, and a control system. On the ground 17, both sides of the brick car track 14 are equipped with guide rails 4 parallel thereto, and one side of the guide rail 4 is provided with a small manipulator 1 sitting on the ground, and a movable gantry 3 is installed on the guide rail 4. The frame includes a lifting mechanism 6, an X-axis movement mechanism 7, a rotating mechanism 8, and a clamping mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com