Wiper cleaning pot and winding method thereof

A technology of washing pots and washing pots, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve problems such as unreasonable design of wiper washing pots, failure of car wipers, and affecting the use of cars, so as to improve adaptability, The effect of prolonging the service life and increasing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

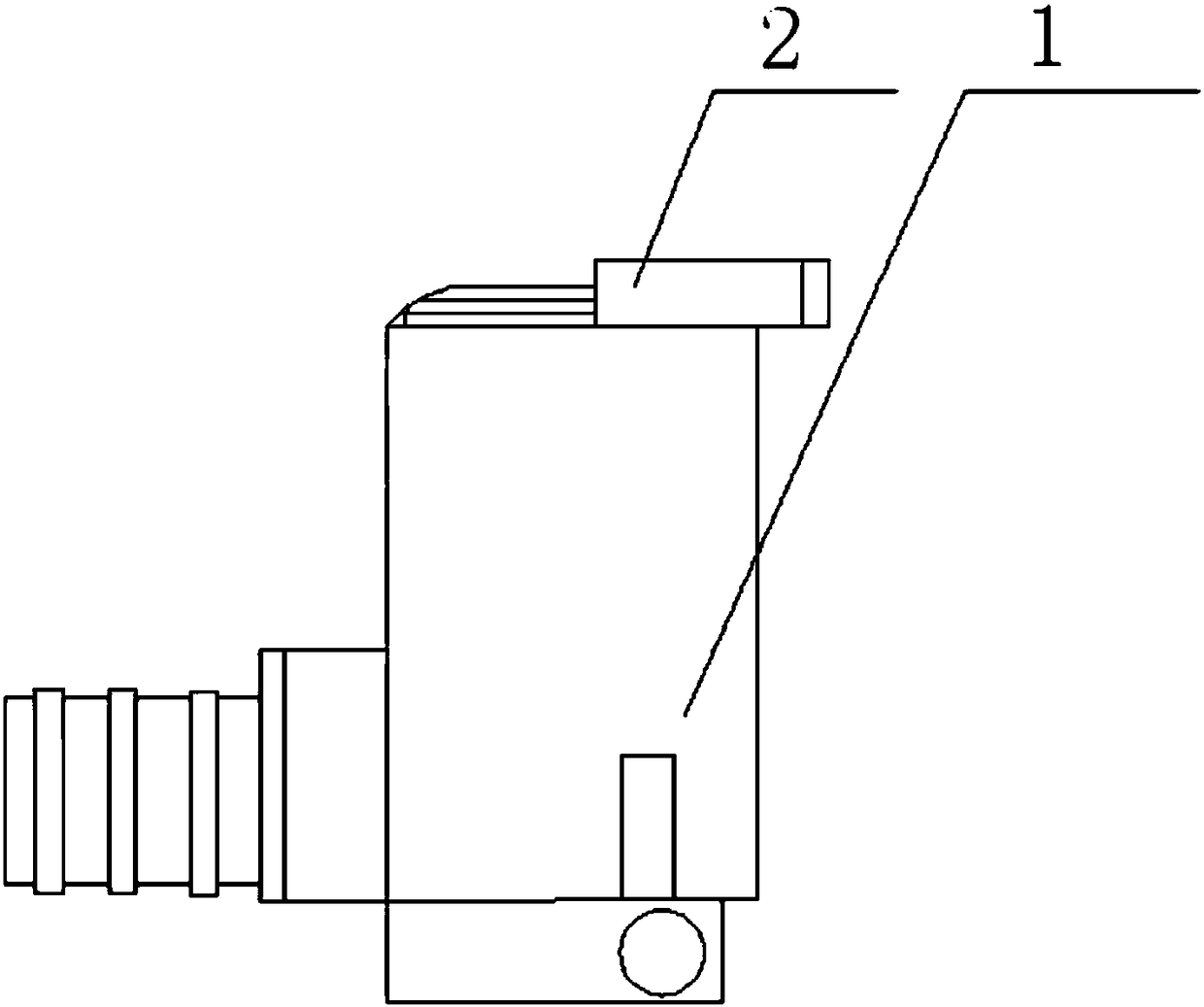

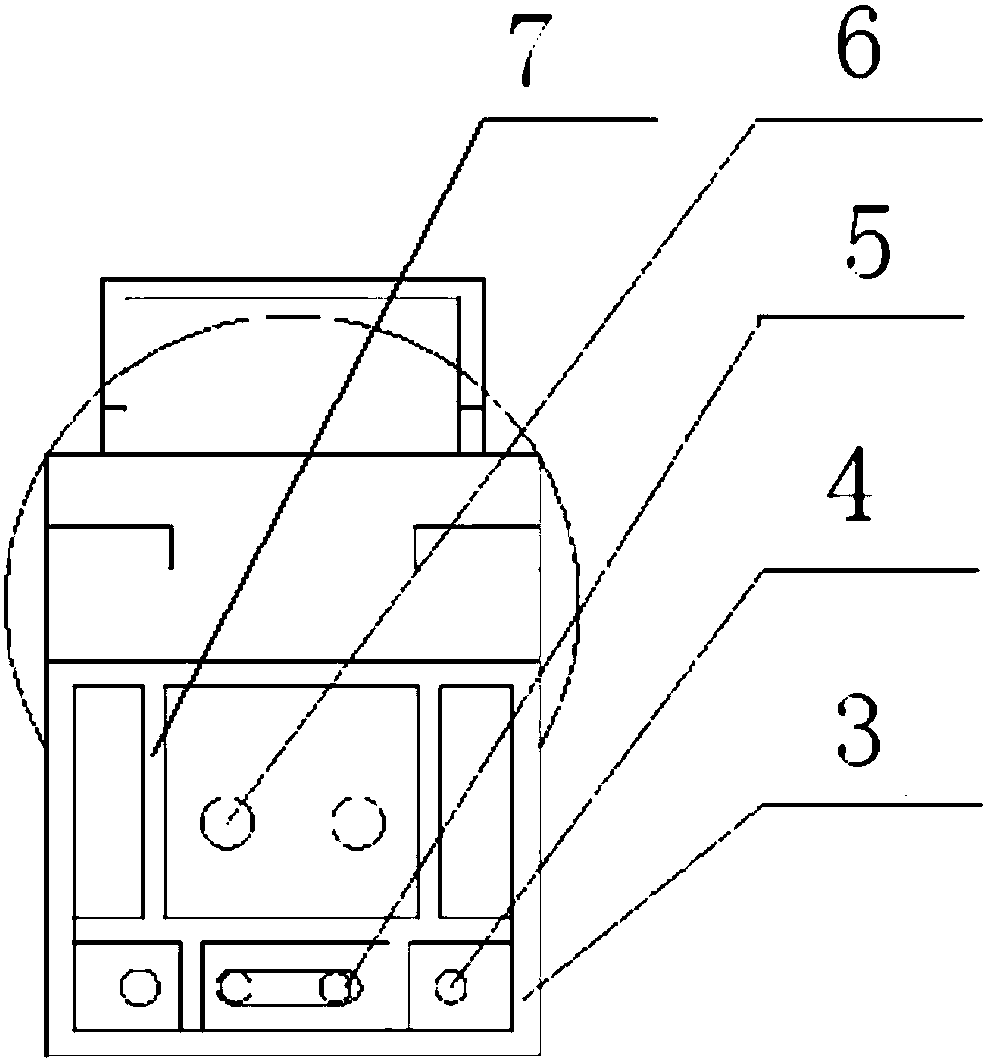

[0018] Please refer to figure 1 , 2 , a wiper washing pot, comprising a loose connecting wire winding device 2 and a pot body 1, the section of one end of the pot body 1 is provided with a winding device 2, and the winding device 2 includes a winding Wire block 3, card slot 7, wire outlet hole 5, threading hole 4 and wire inlet hole 6, described card slot 7 divides winding block 3 into four small pieces, described wire inlet hole 6, wire outlet hole 5 and There are two threading holes 4 respectively, and the described threading hole 6 is arranged in the small block above, and the described threading hole 5 is in the small block below, and the described threading hole 4 is symmetrically installed in the small block on both sides of the threading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com