Screw type self-balancing operation platform for side slope construction

An operation platform and screw-type technology, which is applied in the direction of infrastructure engineering, building structure support, building structure support, etc., can solve the problems of large investment in personnel and turnover materials, difficulty in scaffolding, waste of resources, etc., and achieve convenient operation and disassembly , Reduce construction labor force and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

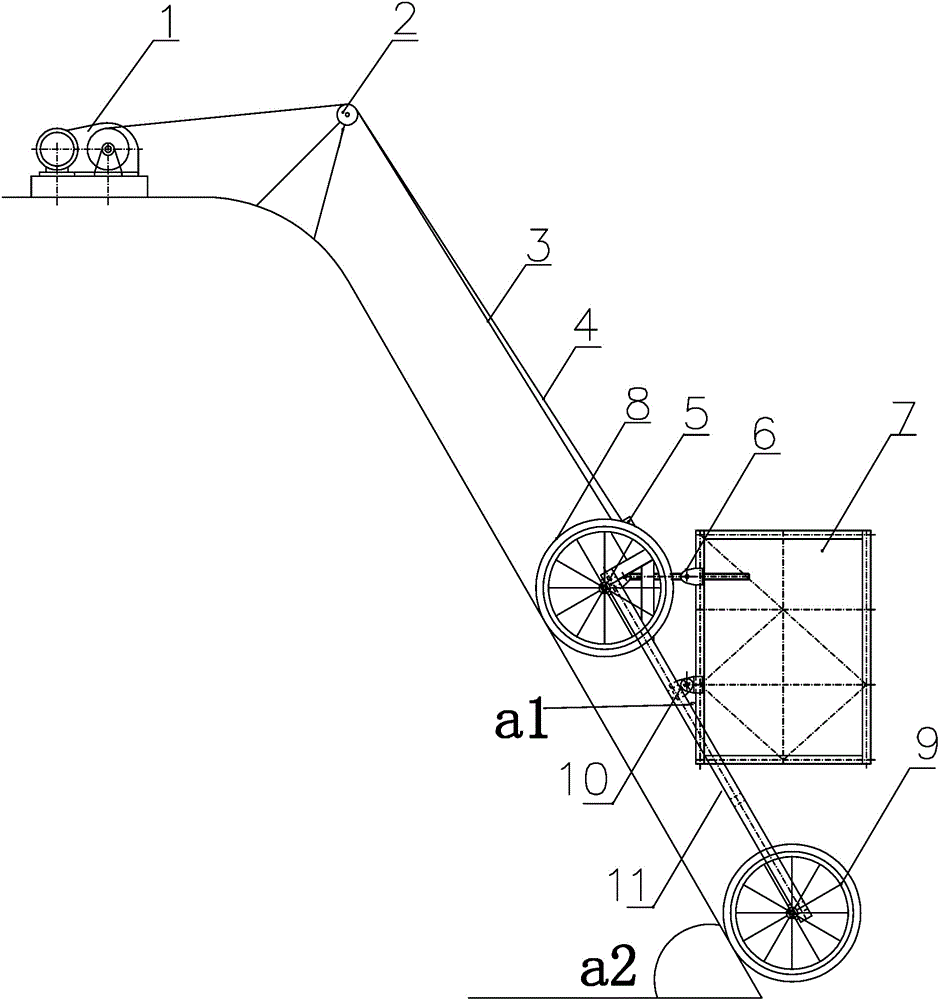

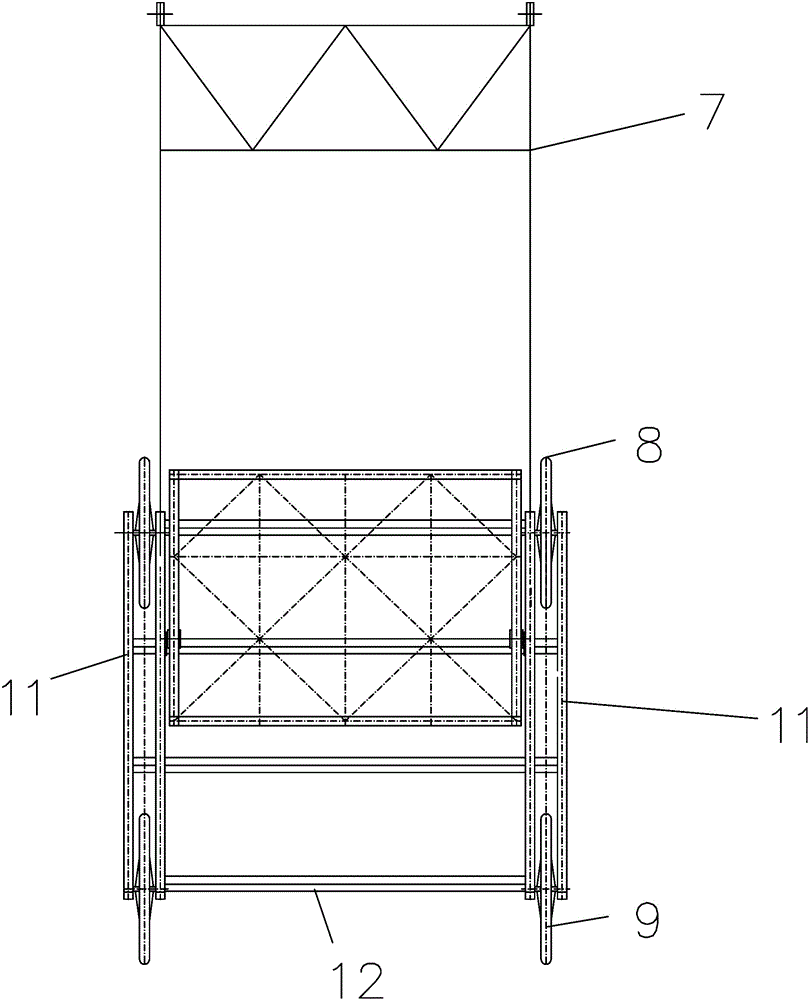

[0022] Such as Figure 1-5 As shown, a screw-type self-balancing operation platform for slope construction includes a hoist 1 and a fixed bracket 2 fixedly installed on the flat part of the top of the slope. The fixed bracket 2 is located below the hoist 1. The surface operation trolley is connected, and the other end of the steel wire rope is connected to the hoist 1 by bypassing the fixed pulley on the fixed bracket 2, which is characterized in that:

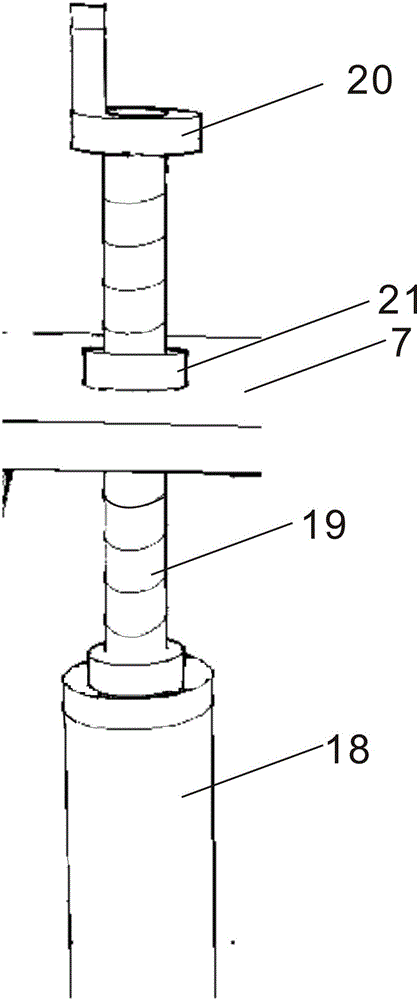

[0023] In the trolley for slope operations, front wheels 8 and rear wheels 9 are respectively installed at both ends of the rectangular frame body 12, and the front wheels 8 and rear wheels 9 on the same side are connected by transmission shafts 11, and the two sides of the square operation platform 7 are connected by screw rods. The structure is connected with the transmission shaft 11, and the screw structure is composed of the hinged structure 10 below and the nut transmission system 6 arranged horizontally near the front w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com